6.3.1.1 Injection Equipment

For gas operation:

When running in gas mode the main components are the gas admission valves and the smaller

needle in the dual fuel injection valve.

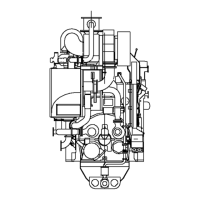

Gas admission valve

The gas admission valves are working as the engine speed regulator and are controlling the

amount of gas fed to each cylinder of the engine. The valve is located on the cylinder head

and the gas is fed into the inlet channel of the cylinder head. The main gas valve is a direct

actuated solenoid valve. The engine automation system (UNIC) adjusts the amount of gas fed

to individual cylinders.

On-engine MCC de-gassing valve (formerly called “venting valve”)

The Main Combustion Chamber line de-gassing valve (MCC) is one of the venting valves of

gas system. Other venting valves are placed in the external gas system. MCC de-gassing

valve is on-engine, at end of gas manifold. Line engines have internally one MCC de-gassing

valve. Vee engines have internally two of them, one per bank. An MCC de-gassing valve

releases the gas pressure when changing from gas mode to diesel mode, or backup mode,

or at engine stopping in gas mode. It acts shortly also at gas mode initiation. It acts also at

automation purging.

When operating the engine in gas mode, the gas is injected through gas admission valves into

the inlet channel of each cylinder. The gas is mixed with the combustion air immediately

upstream of the inlet valve in the cylinder head. Since the gas valve is timed independently of

the inlet valve, scavenging of the cylinder is possible without risk that unburned gas is escaping

directly from the inlet to the exhaust.

6-14 DBAD209883

Wärtsilä 46DF Product Guide6. Fuel System

Loading...

Loading...