45

Daily Repair and Maintenance

Aer adjustment is completed, if feel it is not appropriate to the gap between

plaorm and nozzle, please re-calibrate each posion.

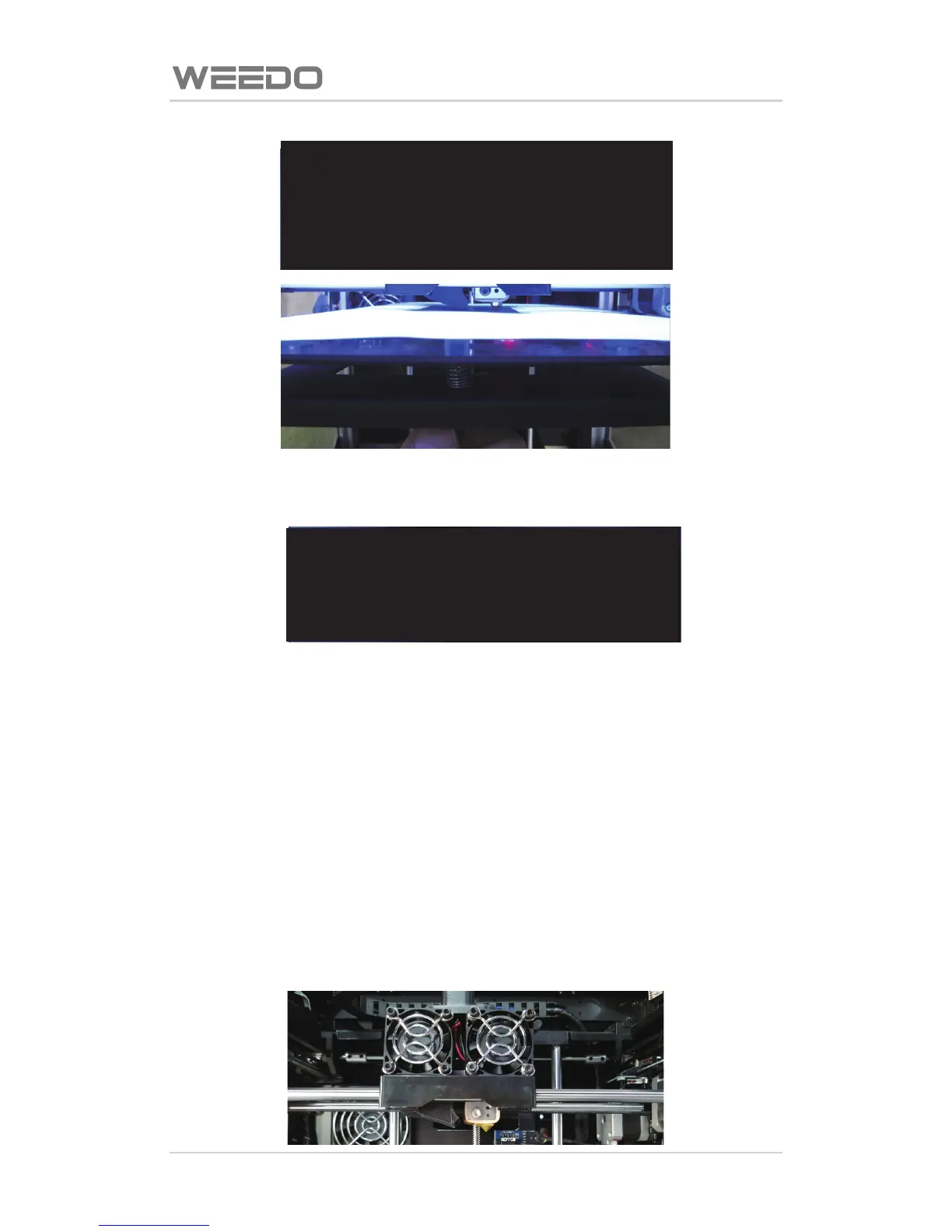

7.1.5. Opcal Sha and Screw Rod Maintenance

In the process of using printer, the two direcons of X and Y depends on the

precise guide rail and sha X screw rod to ensure stable and precise

reclinear moon. Aer add silicon grease lubricaon, it can reduce the

fricon and lower the wear of mechanical moving parts, thus it must be

performed with regular maintenance. It is suggested to perform once

maintenance aer use 1000 hours.

Maintenance method: take out the lubricaon silicon grease from the

accessories box in accompany with printer, and evenly paint them on the

screw rod and opcal sha, and then start the equipment to make each sha

perform full trip for about several mes and to make the silicon lubricaon

grease even distributed on the surface of each sha.

Finished, Press OK

Calibration Complete Press

To Continue

Loading...

Loading...