TECHNICIANS' manual

- English -

15 di 52

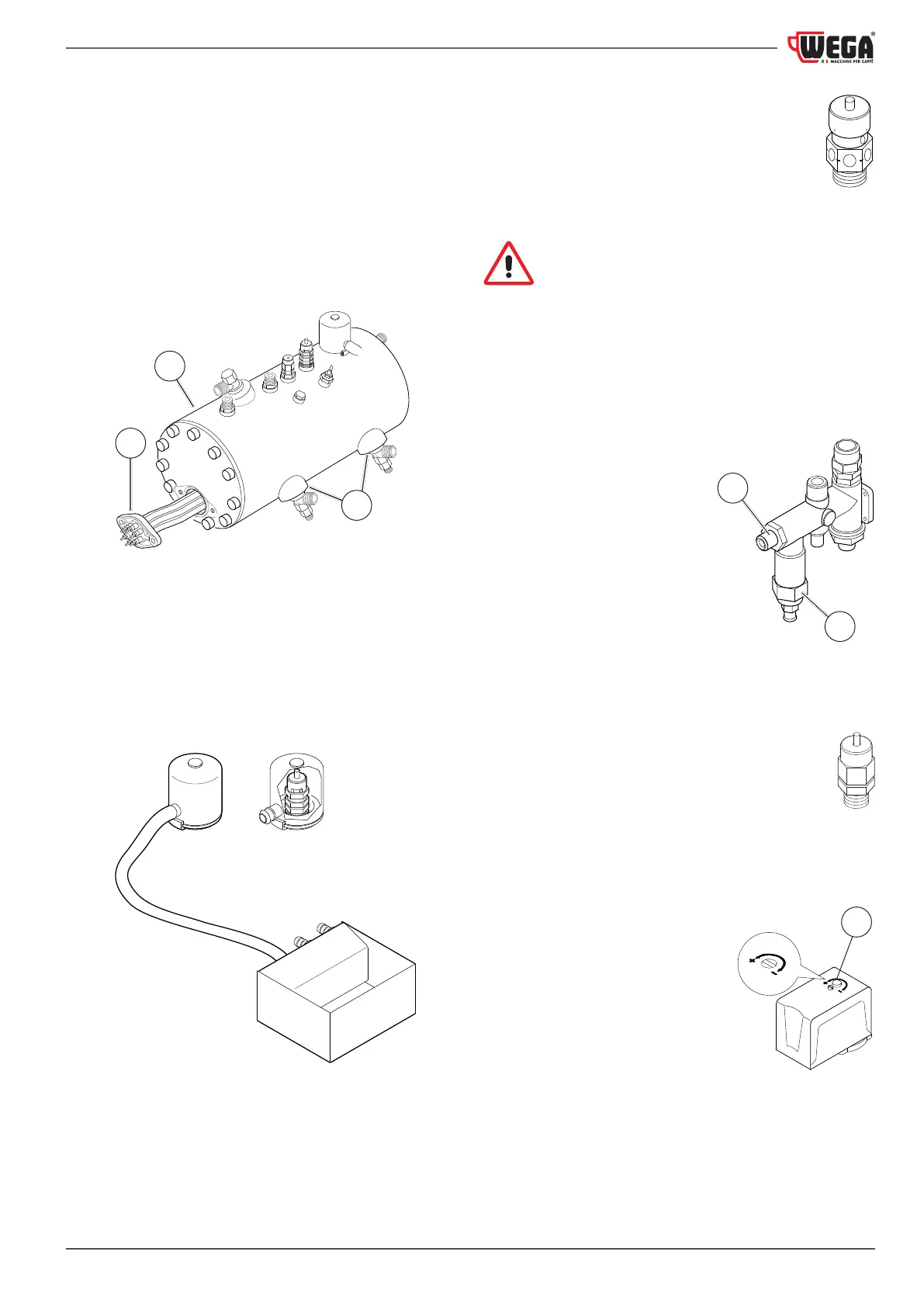

2.8.1 Heating unit

The heating unit is made of copper sheet metal (22). The

heat exchangers (B) are assembled onto this unit and are in

turn connected to the dispensing group. The water used for

dispensing coee is taken directly from the heat exchanger.

During the dispensing process, cold water is sent inside the

exchanger by means of the motor pump. Cold water and the

pre-existing hot water are mixed together inside the heat ex-

changer, in order to obtain the optimal water temperature for

coee infusion.

The heating unit is electrically heated by an electric heating

element immersed in the water (A).

B

A

22

2.8.2 Overflow device

The cover installed on the pressure relief valve makes it pos-

sible to collect any water and steam which may leak from the

heating unit due to a malfunction and channel it to the drain

tray, via a special hose.

2.8.3 Pressure relief safety valve

The pressure relief safety valve has a calibration of

0.19 MPa (1.9 bar) in order to ensure that the pres-

sure in the steam heating unit does not exceed 0.21

MPa (2.1 bar). Should a fault occur, the capacity of

the valve is such as to be able to eliminate all the

excess pressure in the heating unit.

The safety valve should be checked regularly as indi-

cated in Chap. "7. MAINTENANCE AND CLEANING" on

page 31.

2.8.4 Multifunctional dispenser

It consists of an expansion valve and an internal check valve.

• Expansion valve (A): The cold water sent from the pump to

the heat exchangers is heated. This heating causes an in-

crease in the volume of water. To

limit pressure increases in the

hydraulic circuit, the valve limits

the maximum internal pressure

of the circuit to 1.2 MPa (12 bar).

• Internal check valve (B): Its

function is to prevent water

from backflowing into the ma-

chine’s internal hydraulic circuit

from the heat exchangers.

2.8.5 Negative pressure valve

The purpose of the negative pressure valve is to pre-

vent liquids from back-flowing through the steam

nozzle when they are being heated. Furthermore, the

excess air inside the heating unit is removed during

the machine's heating phase.

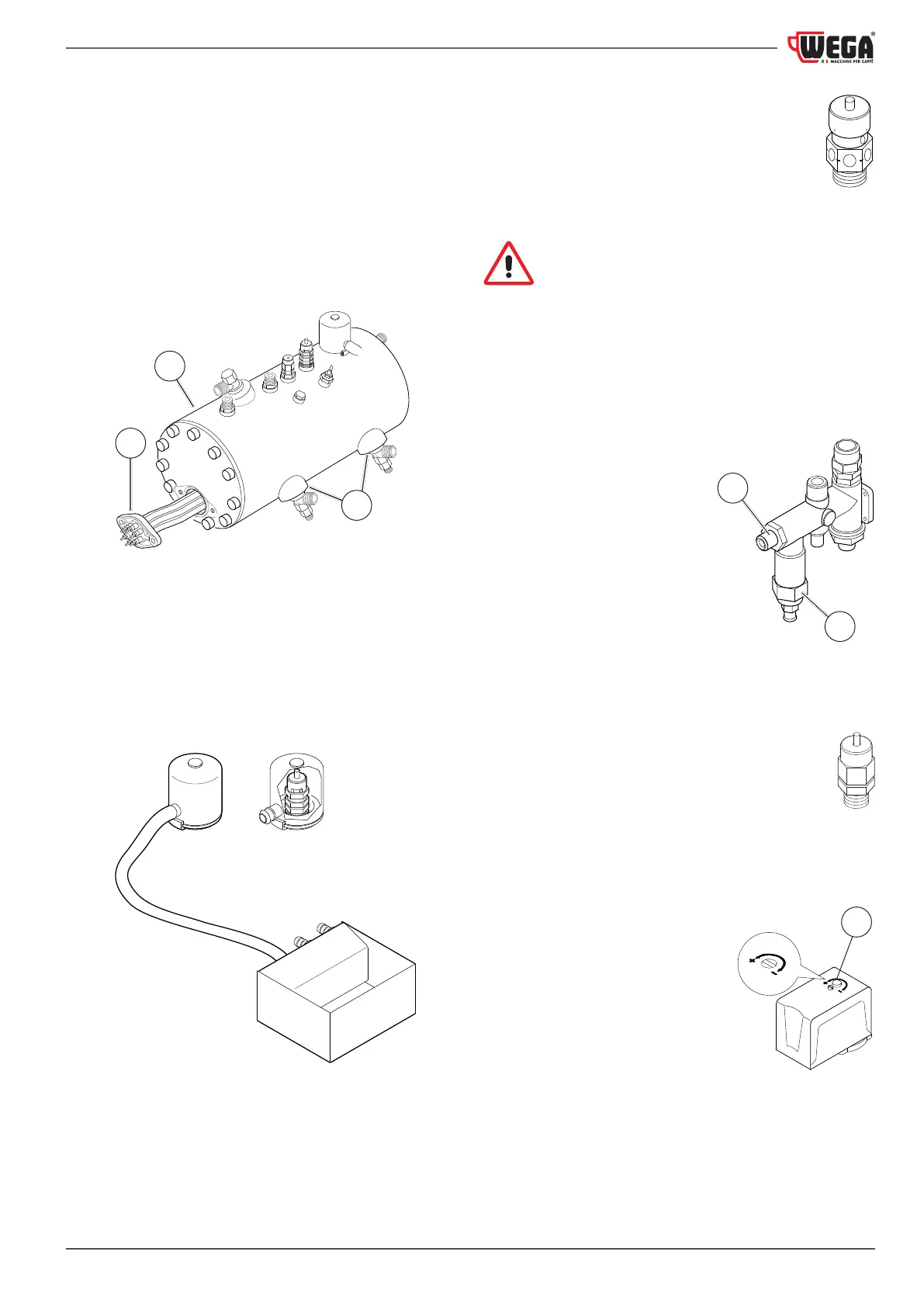

2.8.6 Pressure switch

The pressure switch makes it possible

to control the heating unit pressure by

activating or bypassing the heating ele-

ment in the heating unit. Any pressure

switch calibration can be carried out

with the machine in operation by turn-

ing the screw (A) located on the body of

the component.

B

A

A

Loading...

Loading...