Do you have a question about the Wega MyConcept EVDP 2GR and is the answer not in the manual?

Explains the manual's structure, components, and reading conventions for clarity and understanding.

Provides instructions for proper storage of the manual to ensure its longevity and accessibility.

Details the process for updating the manual and outlines technician responsibilities for revisions.

Identifies the intended users of the manual and the operations assigned to them.

Explains uncommon terms, abbreviations, and pictograms used throughout the manual.

Explains where to locate the machine's identification data on the nameplate and conformity declaration.

Provides an overview of the machine's components, function, and compliance with EU directives.

Defines the specific uses the espresso machine is designed for and highlights prohibited uses.

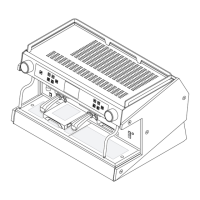

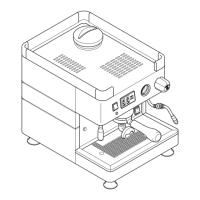

Illustrates and labels the external components of the espresso machine for identification.

Illustrates and labels the various internal components within the machine's structure.

Presents technical data in a table and explains the significance of the CE marking.

Outlines essential safety measures and compliance requirements for all handling operations.

Specifies the required Personal Protective Equipment (PPE) for safe transport of the machine.

Provides key technical specifications regarding the machine's dimensions and weight.

Instructions for safely unloading and handling the machine while it is still in its packaging.

Details the process for safely removing the machine from its packaging before installation.

General information regarding the proper storage of the machine before its installation.

Procedures for storing the machine safely after it has completed its operational life.

Essential safety measures and electrical system requirements for a secure machine installation.

Specifies the required Personal Protective Equipment (PPE) to be used during the installation process.

Defines the necessary environmental conditions, including temperature and humidity, for machine operation.

Guidelines for preparing the installation environment, ensuring adequate space and lighting.

Requirements for the support base to ensure stability, ergonomics, and safety for the machine.

Instructions and diagrams for drilling the support base to accommodate necessary connections.

Details the procedures for connecting the machine to the water supply, including materials and safety norms.

Instructions for safely connecting the machine to the electrical supply, including safety standards.

Important safety measures to observe during the machine's initial start-up and commissioning.

Steps involved in correctly preparing the filter holder for coffee dispensing.

Instructions on how to adjust the coarseness of coffee grounds using the grinder-dispenser.

Details on adjusting the milk temperature and foaming consistency using the autosteamer.

Procedures for correctly turning the machine on, off, and following display prompts.

Steps for replacing the water in hydraulic circuits during installation to ensure purity.

Instructions on how to access machine information, software versions, and serial numbers via the display.

Describes the two primary methods for accessing the machine's programming menu: USB stick and password.

Step-by-step guide for accessing programming functions using a USB stick.

Instructions for accessing programming features using a password, including password changes.

Summarizes the machine's programming sections, involved parameters, and planned operations.

Instructions on how to view and reset maintenance cycle data, water consumption, and grinder wear.

Allows programming of machine services, including boiler pressure, temperatures, and boost phase settings.

Enables programming and management of automatic washing cycles, including duration and intervals.

Enables viewing dispensing information such as time, flow, and temperature during coffee preparation.

Allows setting specific parameters for coffee dispensing, focusing on group and boiler temperatures.

Provides the functionality to select the preferred language displayed on the machine's interface.

Allows users to name and customize coffee blends, facilitating selection of preferred recipes.

Enables checking machine anomalies over time and resetting the alarm log by date or type.

Manages water softeners and filters, including displaying water consumption and programming replacement warnings.

Allows programming of all machine parameters, referring to the comprehensive parameter table.

Manages machine maintenance schedules, including cycles, dates, and dose configurations.

Facilitates software updates and data loading/saving using a USB stick connection.

Monitors real-time operating data such as temperatures, pressures, and flow rates.

Lists and allows resetting of partial and total counts for coffee and tea deliveries.

Checks boiler efficiency by monitoring temperature changes and performance over time.

Allows resetting of user, technician, or factory programming data to initial values.

Steps for connecting the machine to a WiFi network, including SSID choice and security settings.

Essential safety measures to be followed during all maintenance and cleaning operations.

Specifies the required Personal Protective Equipment (PPE) for performing maintenance and cleaning tasks.

Details routine maintenance tasks, their frequency, and type of intervention for machine components.

Procedures for maintaining the machine after periods of inactivity lasting over one week.

Procedures for maintaining the machine after extended inactivity periods exceeding one month.

Weekly cleaning procedures for the perforated disk and containment ring of the dispensing group.

How to perform checks on the pressure relief safety valve to ensure its proper operation.

Instructions for checking the non-return drain valve's functionality for correct machine operation.

Procedures for maintaining the water filter, including hardness detection and bypass configuration.

Step-by-step guide for regenerating the water softener to maintain its effectiveness.

A comprehensive guide to troubleshooting common machine problems and their corresponding corrective actions.

General instructions and specific procedures for cleaning various parts of the coffee machine.

Detailed procedures for cleaning the cappuccino maker after use to ensure hygiene and performance.

Daily and weekly cleaning instructions for coffee filters and their respective holders.

Instructions for performing both scheduled daily and manual washing of the dispensing groups.

Daily cleaning procedures for the steam nozzle and autosteamer to maintain optimal function.

Information regarding the replacement of components and the availability of original spare parts.

Lists common alarm codes, their potential causes, and recommended actions for resolution.

Procedures for handling short periods of machine inactivity, including reactivation steps.

Procedures for handling extended periods of machine inactivity, including disconnection and draining.

Instructions for dismantling the machine, referencing the installation procedure in reverse.

Guidelines for the proper disposal of the product, particularly within the European Union.

Information regarding the internal button lithium battery and its environmentally compliant disposal.

Diagram illustrating the connections and layout of the electronic control unit.

Diagram showing the connections between the control unit and various machine components.

Diagram detailing the display control unit and its wiring connections to the groups.

A comprehensive diagram illustrating the flow and components of the machine's hydraulic system.

| Number of Groups | 2 |

|---|---|

| Power | 3700 W |

| Voltage | 230 / 400 V |

| Weight | 73 kg |

| Product Type | Espresso Machine |

| Model | MyConcept EVDP 2GR |

| Brand | Wega |

| Frequency | 50/60 Hz |

| Material | Stainless steel |

| Dimensions (depth) | 570 mm |

Loading...

Loading...