TECHNICIANS' manual

- English -

33 di 52

Component Type of operation

Quarterly

Yearly

PRESSURE GAUGE AND

PRESSURE SWITCH

Check that the dosing device and pressure switch are working properly. X

VOLUMETRIC DOSING

DEVICE

Check and clean the volumetric dosing device by removing any oxidation from

the tips.

X

MOTOR PUMP Visually inspect the condition of the machine’s wires. X

If any work is carried out on the machine electronics

when the machine is still live, any guarantee will au-

tomatically be invalidated.

All original spare parts are available from the Manu-

facturer’s website. The Manufacturer may provide the

list of spare parts recommended for the maintaining

the various versions of the machine.

7.4.2 Maintenance after a short period of ma-

chine inactivity

“Short period of machine inactivity” refers to a period of time

exceeding one working week.

If the machine is switched back on after this period, all the wa-

ter inside the hydraulic circuits must be replaced as indicated

in para. 6.7 on page 28.

Furthermore, all periodic maintenance operations must be

carried out, see the previous paragraph.

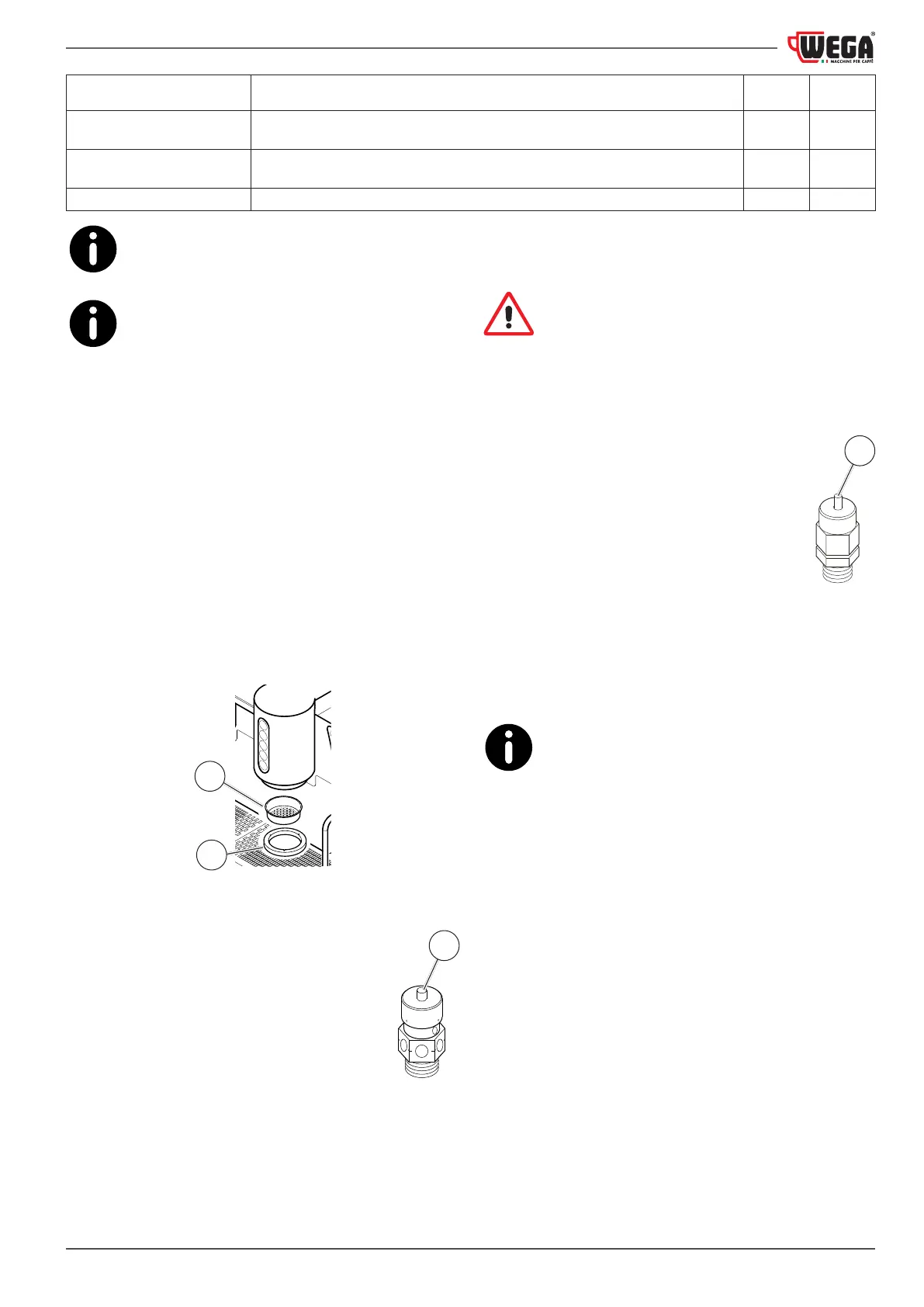

7.4.3 Dispensing group maintenance

Replace the dispensing group's shower screen (A) and group

gasket (B) on a quarterly basis (we recommend only using

original spare parts).

A

B

7.4.4 SAFETY VALVE check

The pressure relief valve is one of the main com-

ponents for machine safety. Therefore, it is impor-

tant to carry out the following checks:

First check:

• Remove the machine's upper grille.

• Use pliers to pull the valve pin (C) upwards.

• If the pin will not budge, it probably means

that the valve is encrusted with limestone and must be

replaced.

Second check:

• Turn the machine o.

• Close o the pressure switch contacts.

• Turn the machine back on and wait for the pressure in the

heating unit to rise.

• Check that the valve is working correctly at the maximum

pressure of 0.19 bar (1.9 bar).

If any malfunctions are detected, the valve must be

replaced. Only use the Manufacturer's original Safety

Valves.

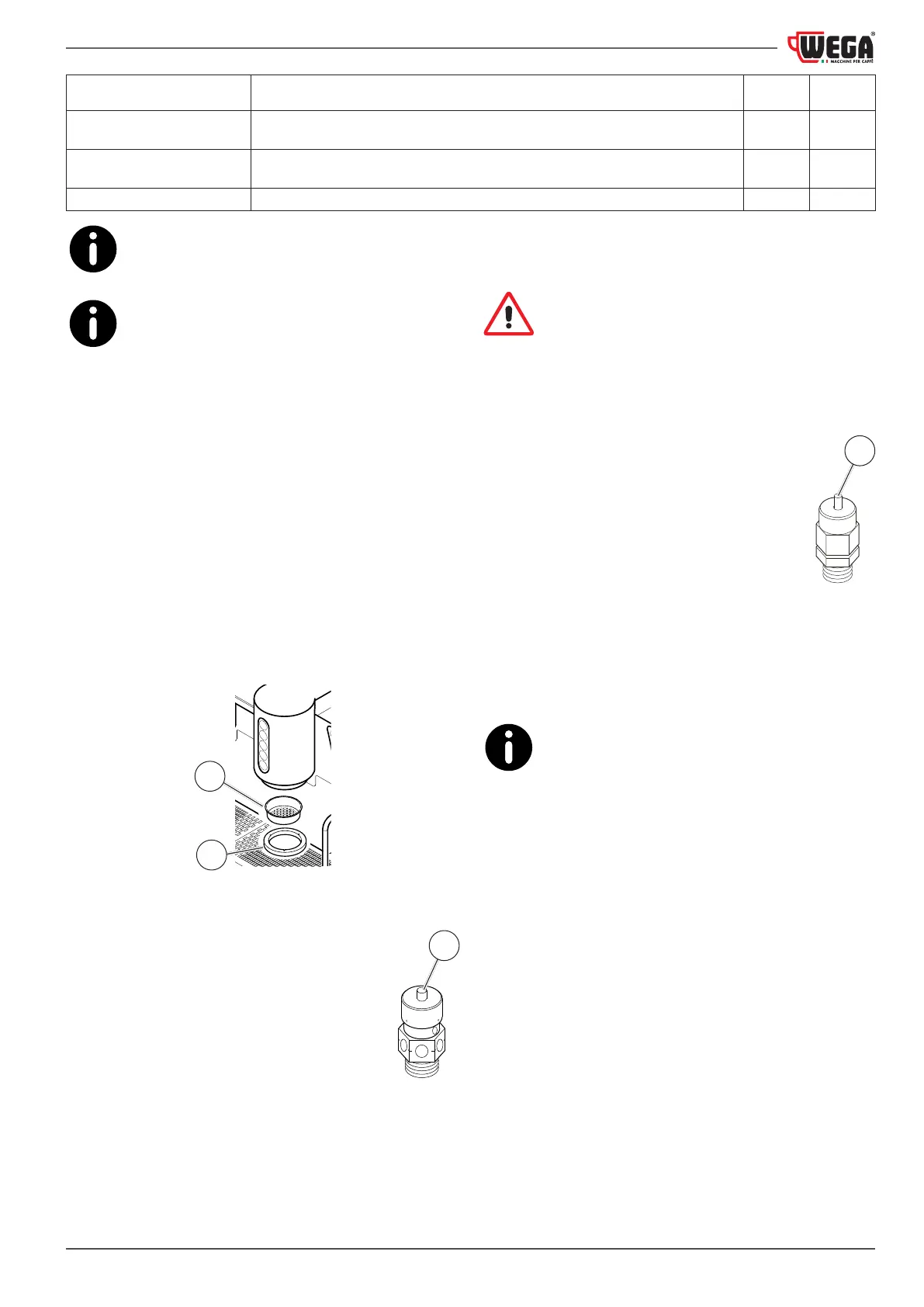

7.4.5 NEGATIVE PRESSURE VALVE check

First check :

• Remove the machine's upper grille.

• Use pliers to push the valve pin (D) downwards.

• If the pin will not budge, it probably means that

the valve is encrusted with limestone and must

be replaced.

Second check:

• Turn the machine o.

• Open the steam valves and release all the pressure from

inside the heating unit.

• Turn the machine back on and check that the valve is clos-

ing normally.

If any malfunctions are detected, the valve must be

replaced.

C

D

Loading...

Loading...