39

8

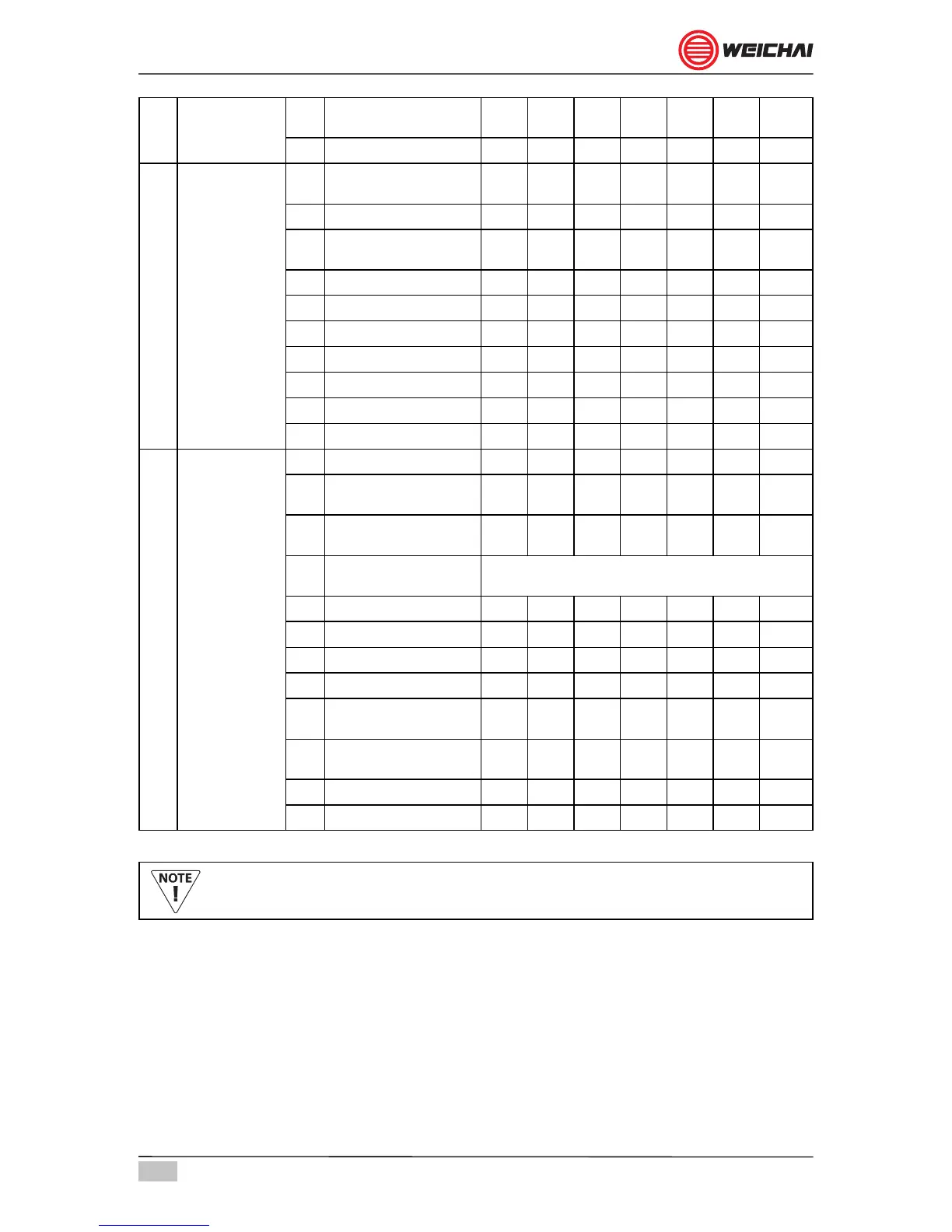

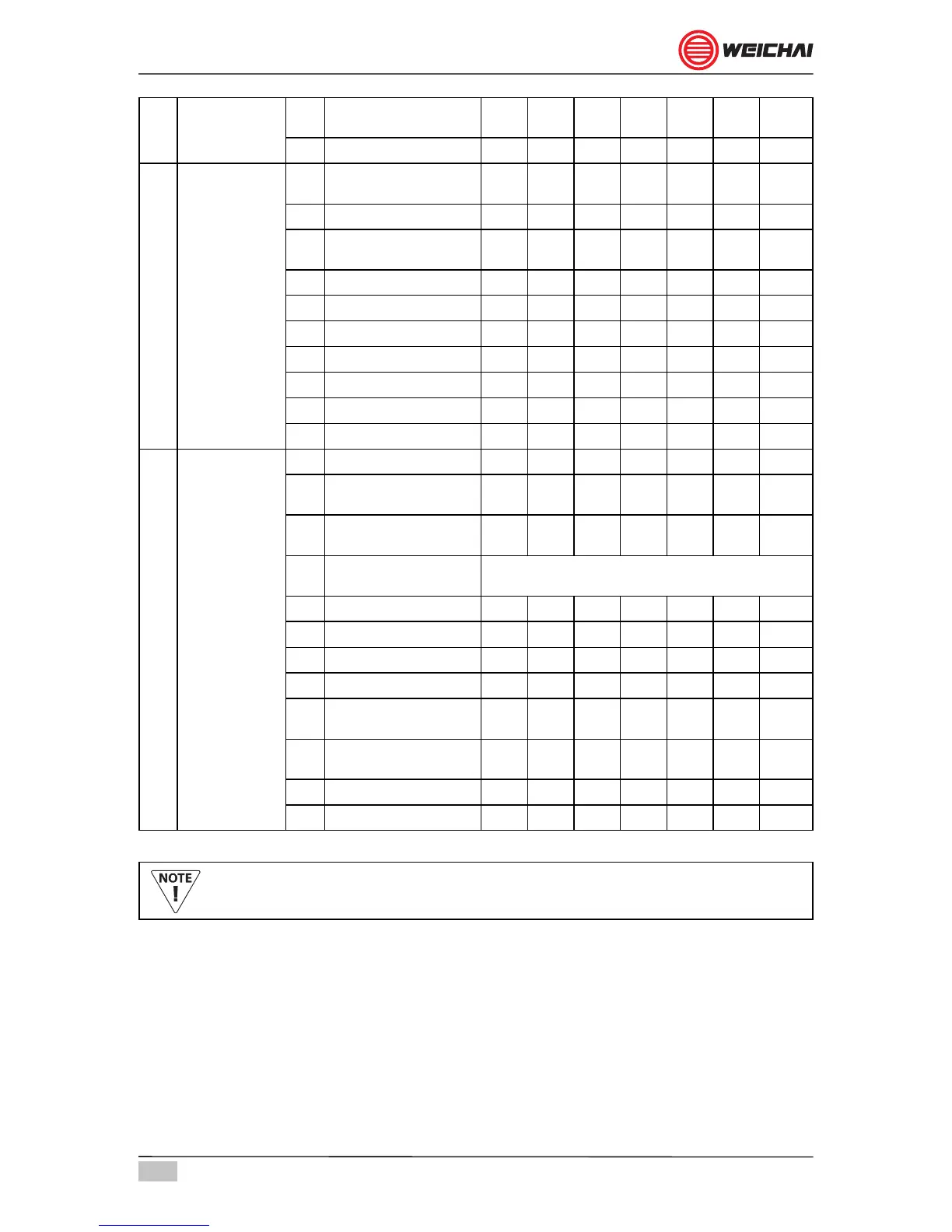

MOVING

ELEMENT

7

CONROD BIG END

BEARING

I R

8 CONROD I I

9

CRANK CASE

- CAM SHAFT

- CRANK

SHAFT - GEAR

TRAIN

1

MAIN BEARINGS &

THRUST BEARINGS

R

2 CAM BUSH BEARING R

3

BEARINGS RELATED

TO GEAR TRAIN

R

4 OIL SEALS R R

5 TAPPET I I

6 CAM SHAFT I

7 CRANK SAHFT I

8 CAM & IDLE GEAR I

9 ROLLER BEARING R

10 FASTNERS I

10

OTHERS SUB

ASSEMBLIES

1 FAN BELT M M R R R R

2

BELT TENSIONOR

PULLEY

R R

3

FLEXIBLE HOSES AND

CLAMP

C C C C C R R

4

SET OF O RINGS AND

GASKETS

REPLACE EVERY TIME WHEN REMOVED

5 STARTER MOTOR M M M M I&S I&S

6 ALTERNATOR M M M M I&S I&S

7 DISPLAY MONITOR M M M M I&S I&S

8 WIRE HARNESS M M M M I&S I&S

9

FUEL SHUT OFF

SOLINOID

M M M M I&S I&S

10

ENGINE STOP

SOLINOID

M M M M I&S I&S

11 VIBRATION DAMPER M M M M I&S I&S

12 GAS OIL SEPARATOR C C C I&S

Table 5.2

Replacement period of engine oil varies according to the operating

conditions as below.

Normal operating condition (the above-listed is normal operation condition, when the oil consumption

is normal): the ambient temperature is normal, and fuel with sulfur content lower than 0.5% (by

weight) is used. Adverse operating condition (oil consumption is high):

1. In tropical climate or cold zone (temperature exceeds +30° or lower than -10°), the oil

drain period shall be half of that un der normal operation condition.

2. When sulfur content of fuel with is 0.5~1.5%, the oil drain period shall be half of that under

normal operation condition.

3. In adverse operating condition with A+B, the oil drain period shall be one fourth of that

under normal operation condition.

Loading...

Loading...