40

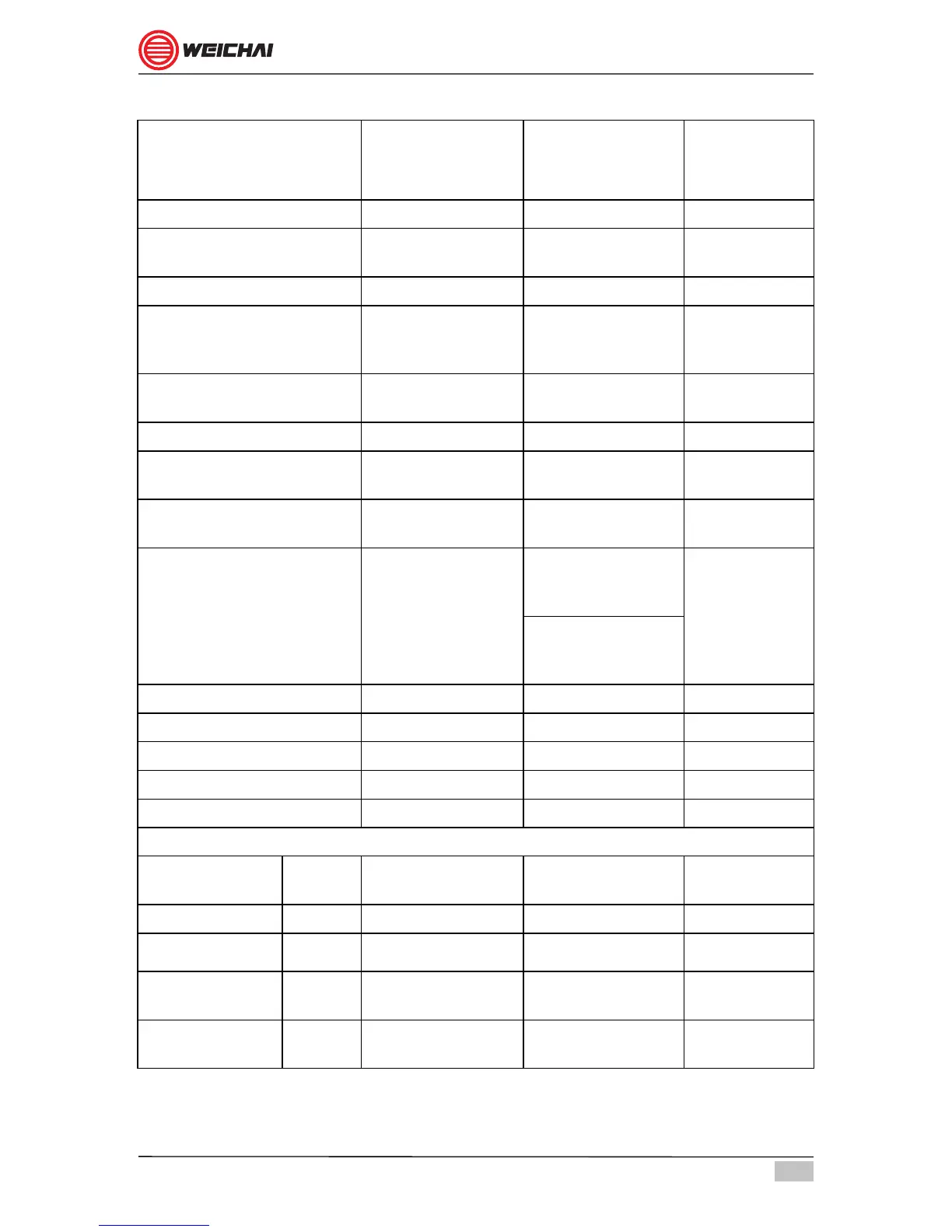

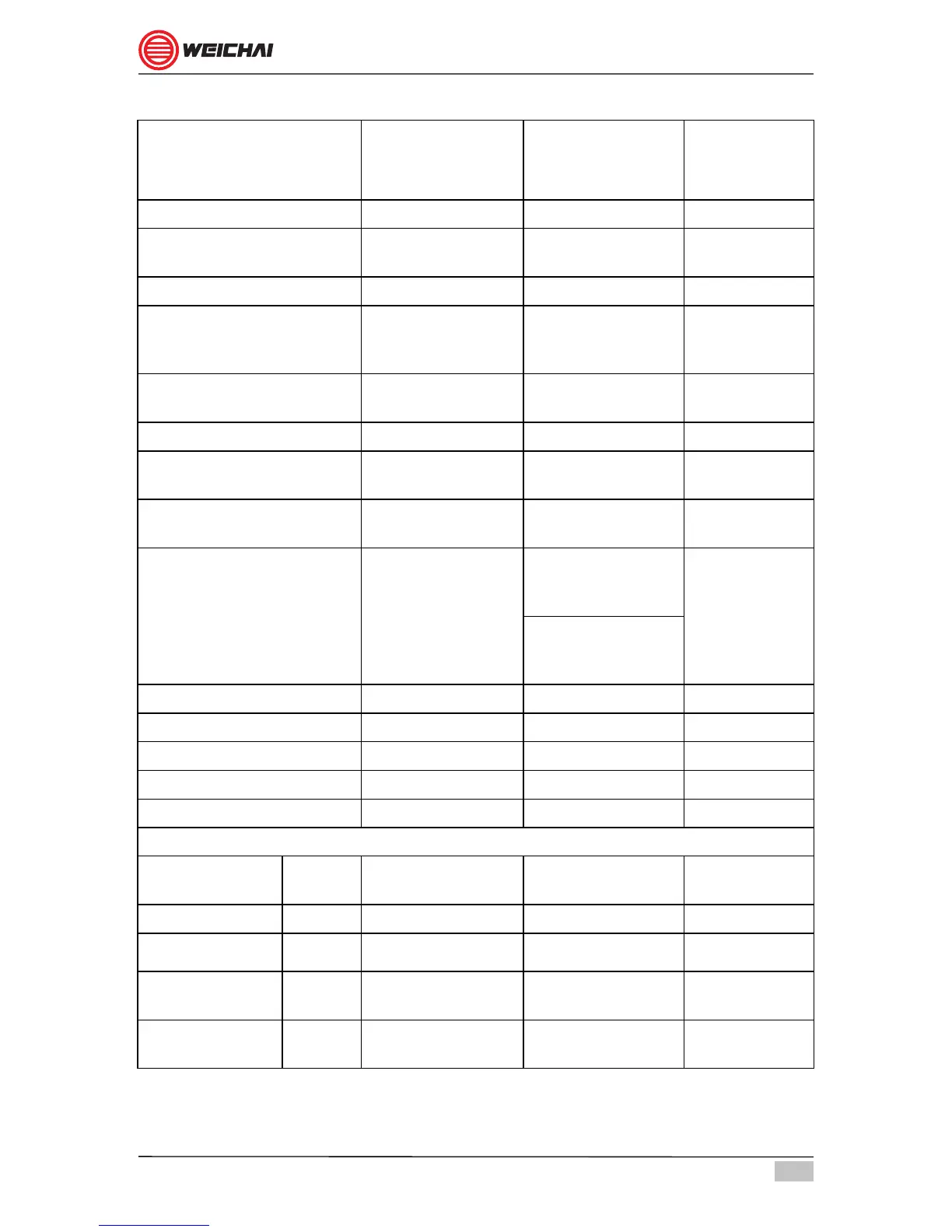

TIGHTENING TABLE AND TORQUE VALUES FOR MAIN FASTENERS

DESCRIPTIONS

SPECIFICATIONS

(SIZE – GRADE)

REQUIREMENTS

ALLOWABLE

TIMES

TO REUSE

Main bearing bolt M18X169 - 10.9 140N.m+210° 2

Crankcase secondary bolt M8X 25 - 8.8

M8X210 - 8.8

8N.m+30

2

Cylinder head main bolt M14X185 - 10.9 60N.m+2×120° 3

Cylinder head secondary

bolt

M12×1.5X195 - 8.8 20+10N.m Seal

with Loctite 262

Sealant

3

Cylinder head secondary

nut

25N.m+2×120°

3

Crankshaft pulley bolt M12×1.5X75 - 10.9 45N.m+135° 2

Bolt for tensional

vibration damper

M10X30 - 8.8 15N.m+30°

2

Flywheel bolt M16×1.5X

120-10.9

105N.m+270°

2

Connecting rod bolt

M14×1.5X

67.5 - 10.9

115N.m+90°

(Manual

tightening)

0

80N.m+153°

(Automatic

tightening)

Idler gear bolt pin M12×1.5X90 - 10.9 105N.m 0

Injector clamping bolt M8X50 - 8.8 8N.m+90 3

Camshaft gear bolt M8X30 - 8.8 8N.m+120° 2

Piston cooling injector bolt M10X25 30N.m 0

Exhaust manifold bolt M10X65 15N.m+60° 2

Standard torque table

Bolt size Grade Torque value Grade

Torque

Value

Standard M6 bolt 8.8 8 Nm 10.9 13 Nm

Standard M8 bolt

8.8 22 Nm 10.9 31 Nm

Standard M10

bolt

8.8 39 Nm 10.9 58 Nm

Standard M12

bolt

8.8 70 Nm 10.9 100 Nm

Table 5.3

Loading...

Loading...