Repairs: Information and Instructions 21

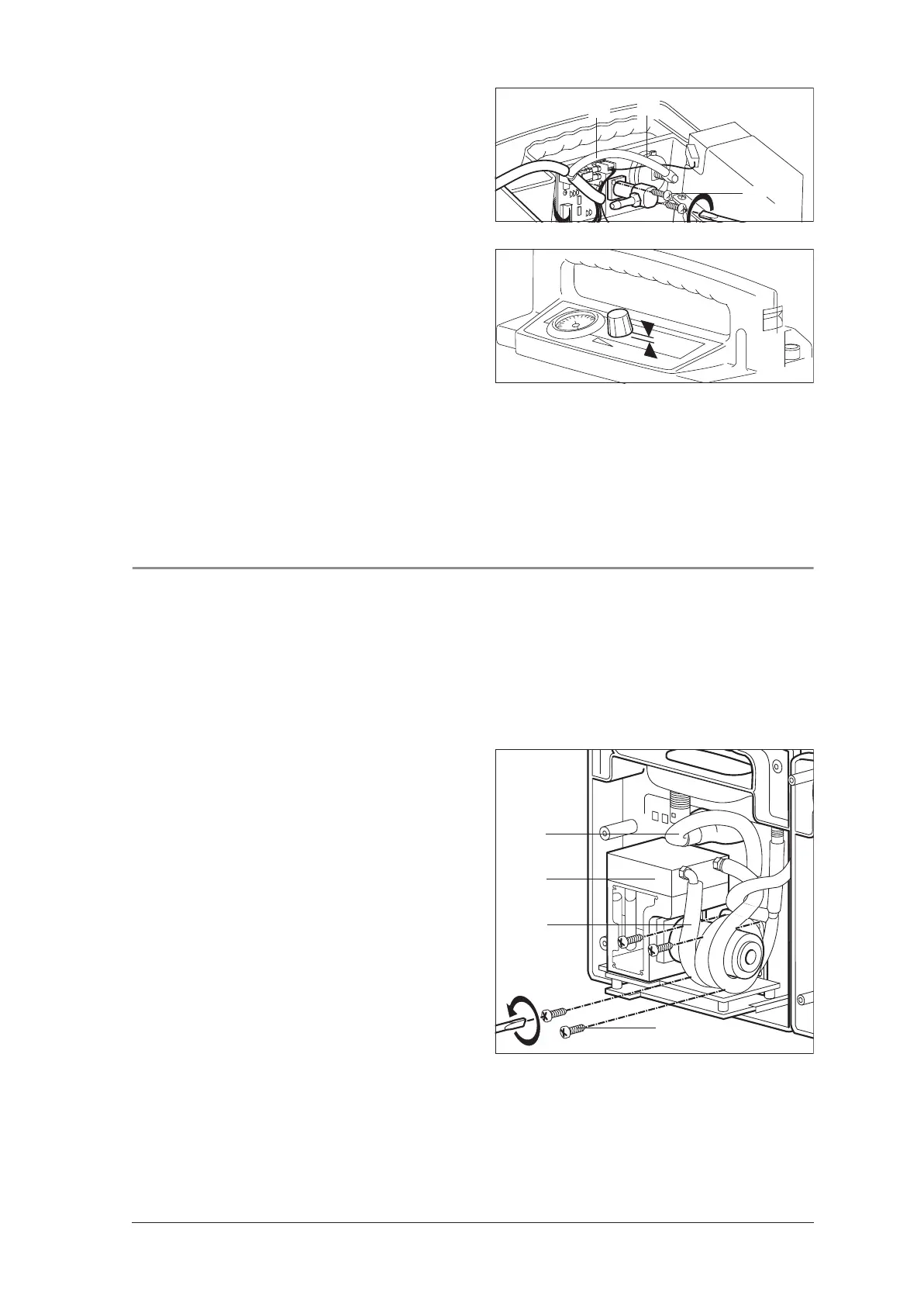

4. Remove tube 58 from vacuum regulator.

5. Unscrew the 2 cylinder-head screws 47 and

remove the faulty vacuum regulator.

6. Fit the new regulator unit 46 in reverse order.

7. When replacing the knob, ensure that the gap

between knob and keyboard membrane (with

the spindle screwed in) is approx. 1.0 mm.

8. Use a 10 mm tubular wrench to tighten the nut

securing knob 44.

9. Insert cap 45 (slit in cap must match ridge in

knob).

10. Close the device (see ”8.3 Closing the de-

vice“ on page 13).

11. Perform a functional check (see ”6.2 Perform-

ing the functional check“ on page 8).

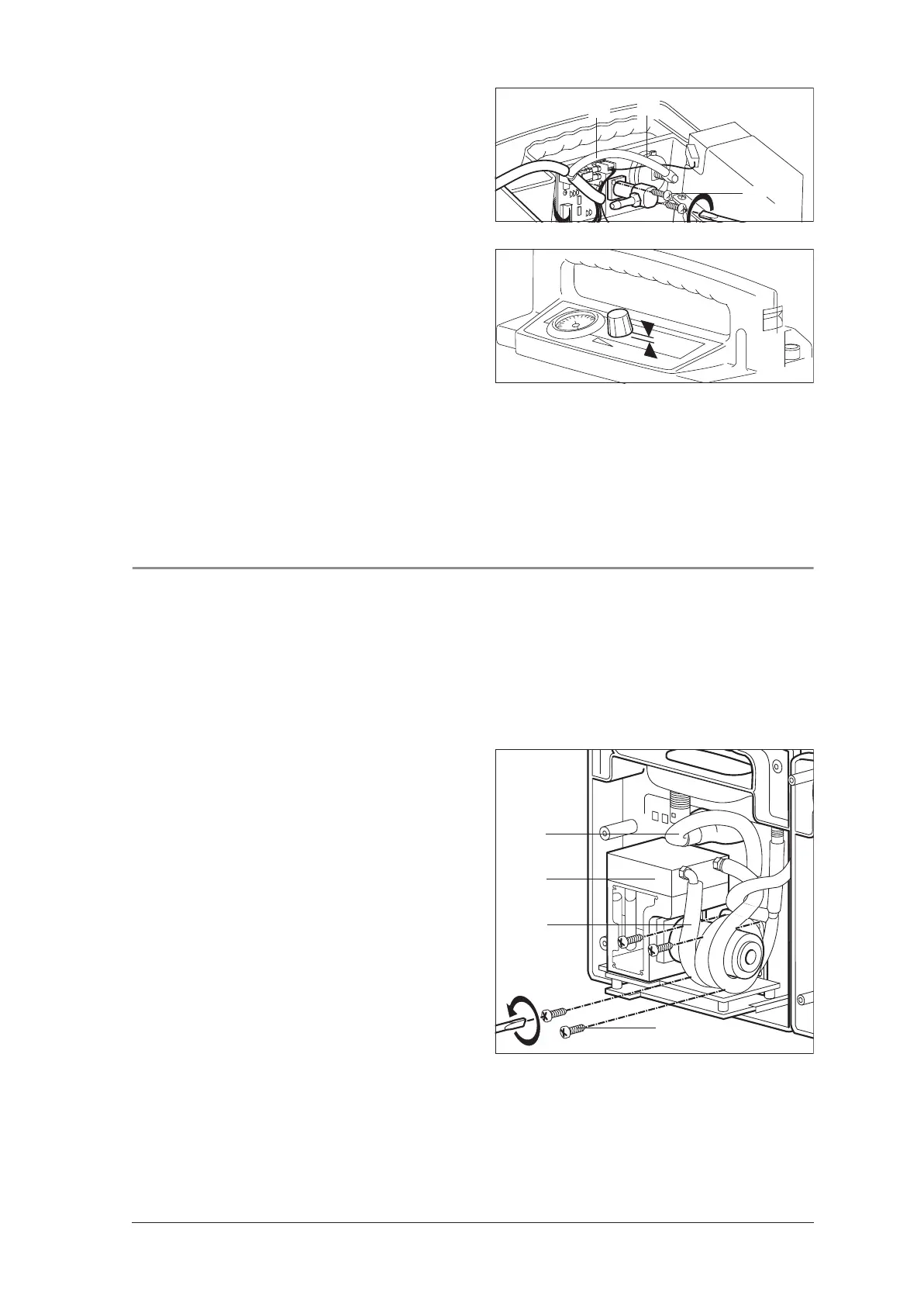

8.12 Fitting new pump

The pump is only available as a complete replacement unit.

Tools and equipment required:

• Phillips screwdriver size 2.

1. Open the device (see ”8.2 Opening the de-

vice“ on page 12).

2. Detach silicone fabric tube 56 from inlet port of

pump.

3. Detach rolled-up silicone tube 57 from muffler

connection.

4. Unscrew 4 screws 41 from support.

5. Detach tube 57 from faulty vacuum pump, at-

tach it to outlet of new pump 44 and wind it

round motor.

6. Finish fitting the new vacuum pump in reverse

order.

7. Close the device (see ”8.3 Closing the de-

vice“ on page 13).

8. Perform a functional check (see ”6.2 Perform-

ing the functional check“ on page 8).

47

46

58

1mm

57

56

41

44

Loading...

Loading...