20 Repairs: Information and Instructions

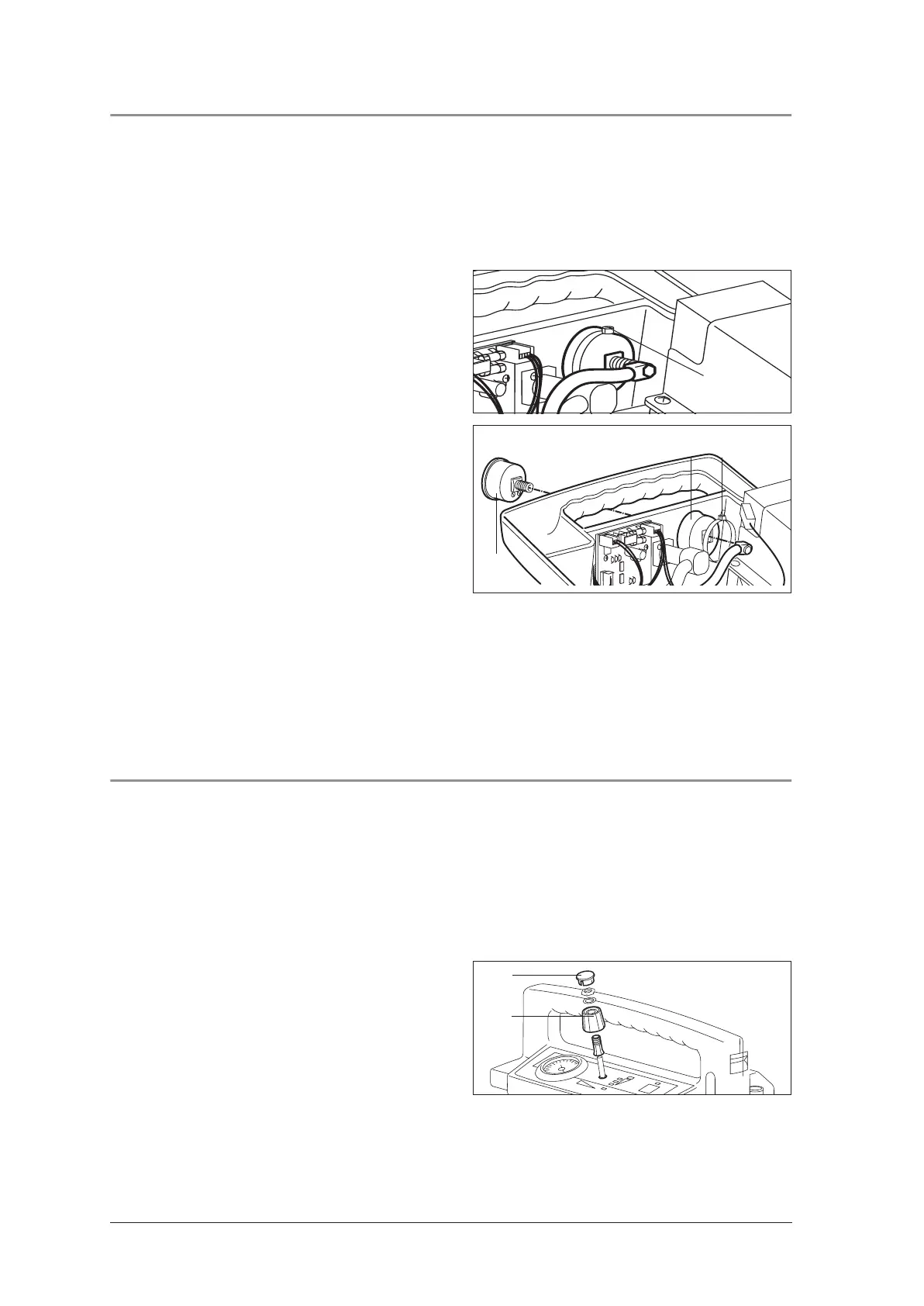

8.10 Fitting new pressure gage

Tools and equipment required:

• Phillips screwdriver size 2.

1. Open the device (see ”8.2 Opening the de-

vice“ on page 12).

2. Use a 7mm open-end wrench to unscrew the

tube connection from the pressure gauge.

3. Cut open cable tie 43.

4. Carefully push faulty pressure gauge upward

out of resilient ring 42.

5. Using a little methylated spirits, carefully insert

the new pressure gauge 1 downwards into the

resilient ring 42 (making sure to align it correct-

ly). Roll the rubber cuff onto the pressure gauge

with your fingers.

6. Secure the pressure gage by fitting cable tie

43 around the resilient ring.

7. Attach the tube connector to the pressure

gauge using a 7mm open-end wrench.

8. Close the device (see ”8.3 Closing the de-

vice“ on page 13).

9. Perform a functional check (see ”6.2 Perform-

ing the functional check“ on page 8).

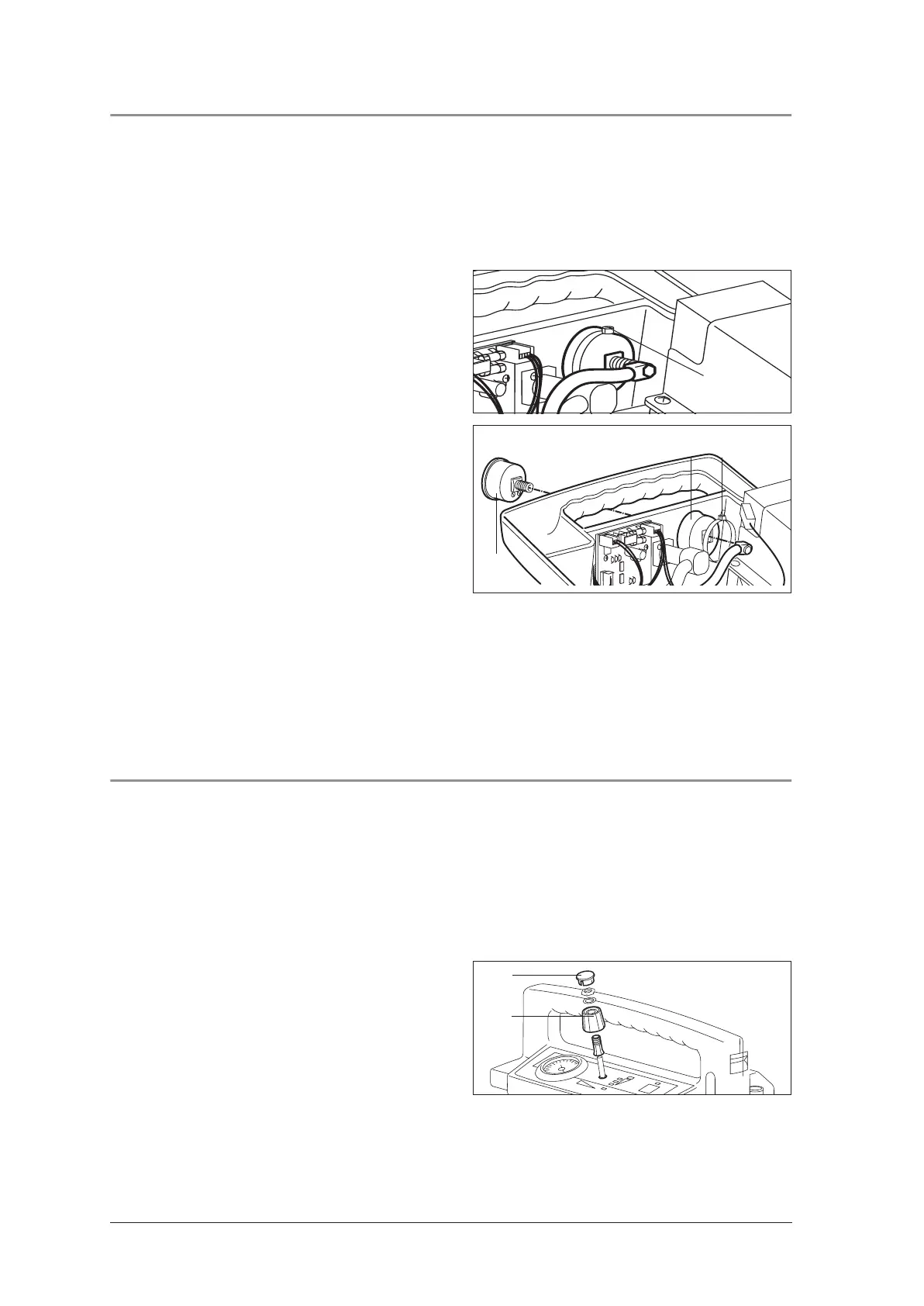

8.11 Fitting new vacuum regulator

Tools and equipment required:

• Phillips screwdriver size 2,

• Tubular wrench, 10 mm.

1. Open the device (see ”8.2 Opening the de-

vice“ on page 12).

2. Carefully remove cap 45 of knob 44, using a

razor blade (for example).

3. Use a 10 mm tubular wrench to unscrew the

knob.

43

42

1

43

45

44

Loading...

Loading...