.

26 © Weldclass 2019 | E.&O.E. | Edition 2.2

7.1 MIG Welding

WARNING! Before changing the feed roller or wire spool, ensure that the mains

power is switched off.

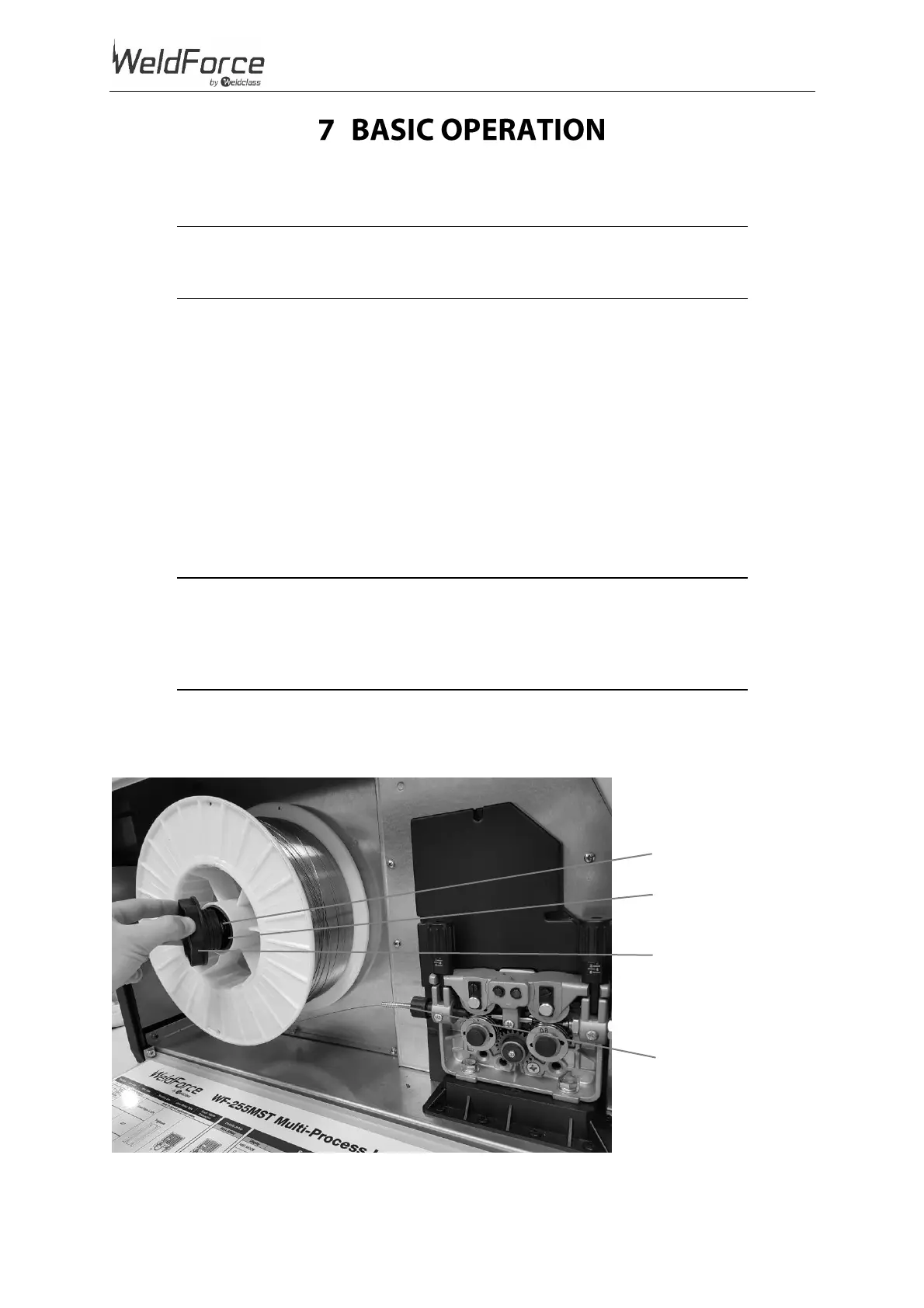

7.1.1 Fitting Wire Spool – 270/300mm Diameter (15kg)

1. Open the wire feeder compartment door.

2. Remove the Spool Nut (10) by threading it anticlockwise.

3. Fit the wire spool to Spool Post (9), ensuring that the wire exits the spool towards the wire feeder

from bottom the spool.

4. Set the Spool Brake Tension by adjusting the Spool Tension Nut in the middle of the Spool Post

(9). Turn clockwise to increase spool brake tension and anti-clockwise to decrease. The spool

brake tension should be set so that the spool can rotate freely, but does not continue to rotate

once the wire feed stops. This may need to be adjusted as the wire is used up and the spool

weight decreases.

WARNING! Excessive spool brake tension will cause wire feeding issues and affect

welding performance as well as premature failure/wear of wire feed components.

Insufficient brake tension will cause the spool to ‘freewheel’ and the welding wire will

unravel from the spool (known as a ‘birds nest’)

5. Replace the Spool Nut (10) by threading it back on the Spool Post (9).

6. Feed the wire from the spool through the Wire Inlet Guide (12) into the wire feeder.

Figure 17

Loading...

Loading...