.

54 © Weldclass 2019 | E.&O.E. | Edition 2.2

11.12.3 Weld Quality Problems

Other weld problems can be reduced by checking the following points.

Troubleshooting – MIG Weld Quality

Welding arc voltage too high

Decrease voltage or increase

the wire feed speed.

Increase the torch travel speed

and/or decrease welding

current by decreasing the

voltage or decreasing the wire

feed speed.

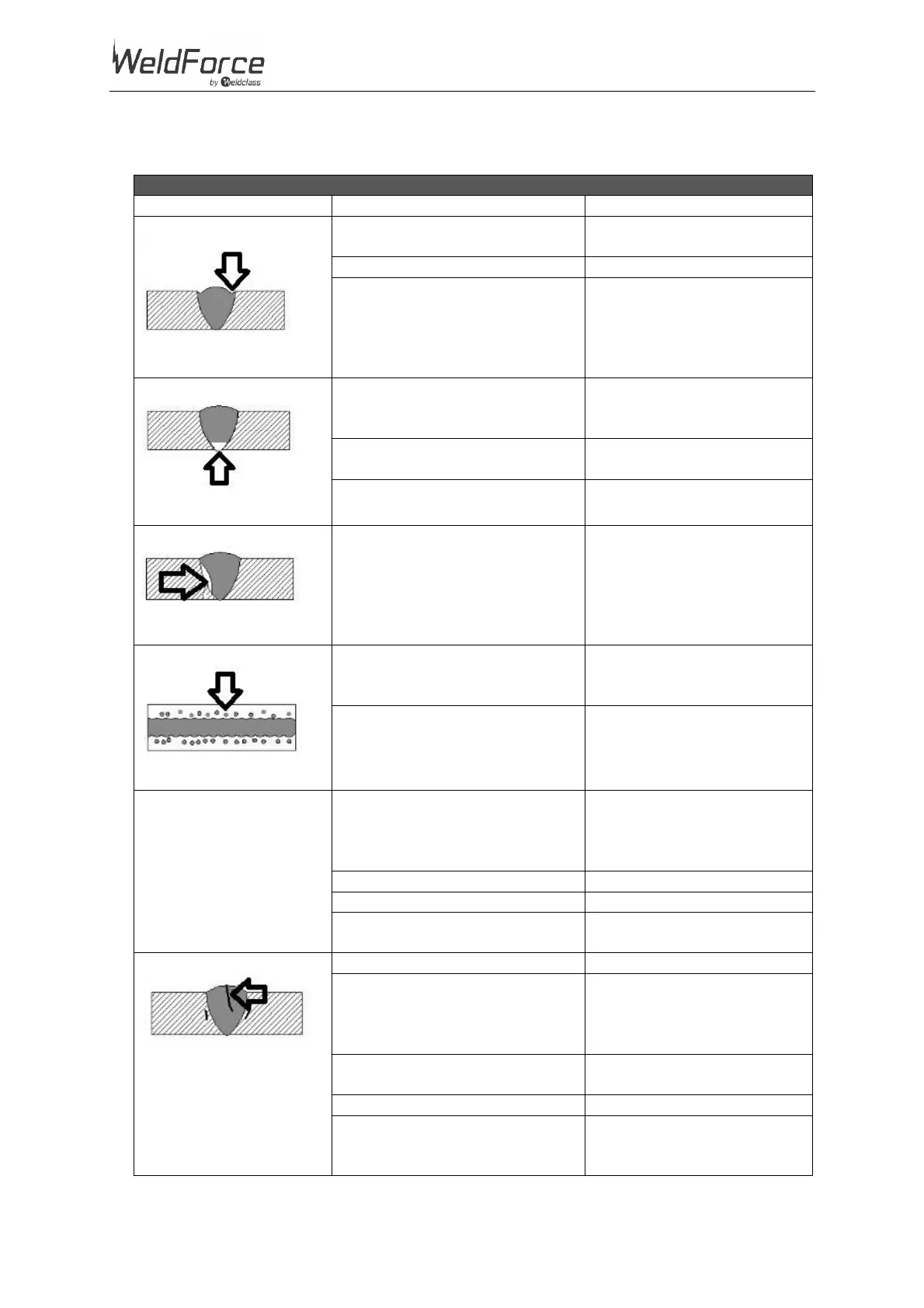

Lack of penetration

Figure 49

Increase welding current by

increasing wire feed speed and

increasing voltage.

Joint preparation too narrow or gap

too tight.

Increase joint angle or gap.

Change to a gas which gives

higher penetration.

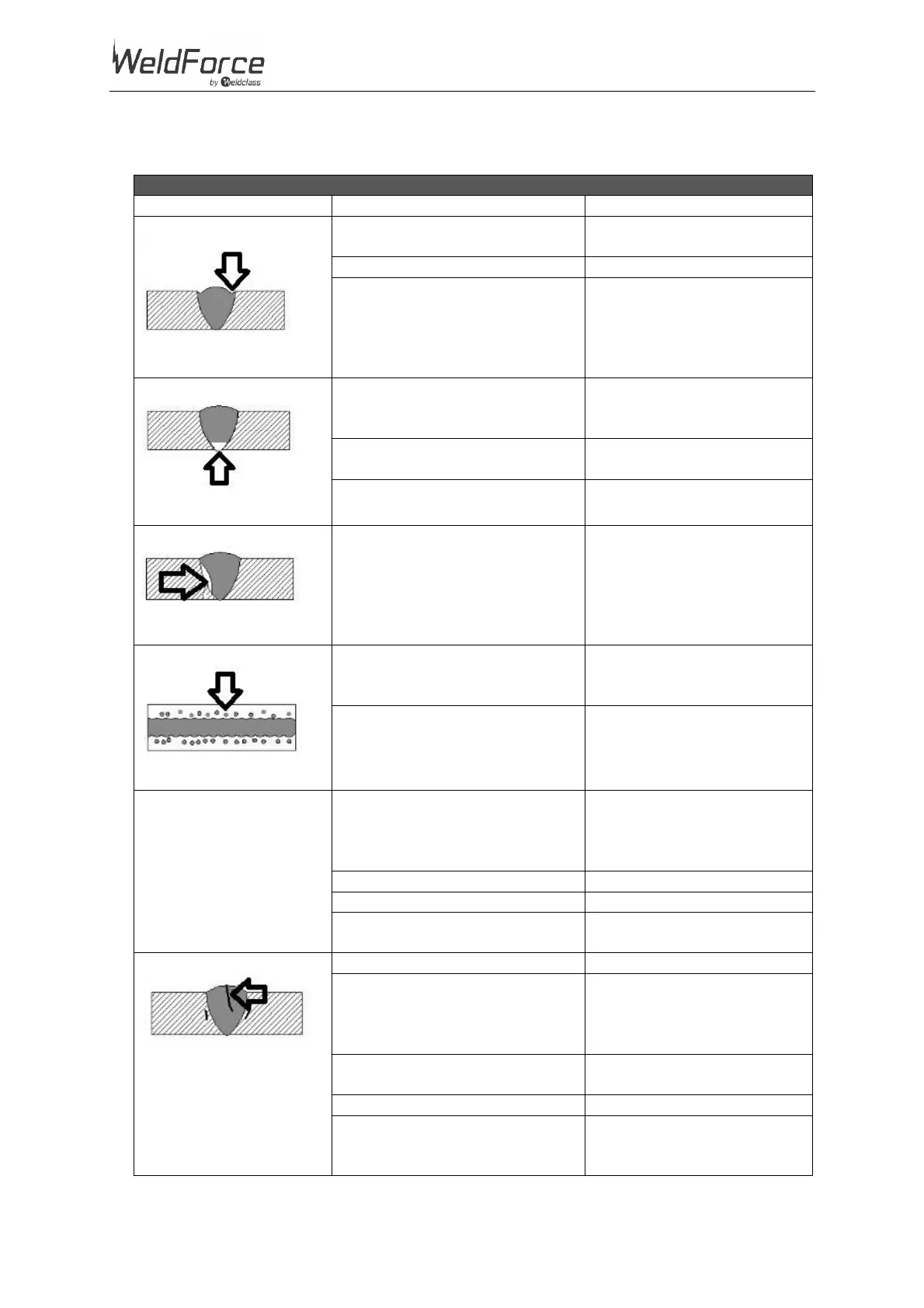

Excessive spatter

Figure 51

Decrease voltage or increase

the Current (Wire Speed)

control/

Increase the voltage or

decrease Current (Wire Speed)

Incorrect voltage and current

settings.

Convex, voltage too low.

Concave, voltage too high.

Adjust voltage and current by

adjusting the voltage control

and the Current (Wire Speed)

control

Insufficient or excessive heat input.

Adjust the Current (Wire Speed)

control or the voltage control.

Weld penetration narrow and deep.

Reduce current and voltage and

increase MIG torch travel speed

or select a lower penetration

shielding gas.

Increase weld metal strength or

revise design.

Slow the cooling rate by

preheating part to be welded or

cool slowly.

Loading...

Loading...