19

AFTER SALES SUPPORT

1300 663 907 CUSTOMERCARE@WINPLUS.COM.AU MODEL: HE170703

PRINTING AND REMOVING MODELS

5.1.1 During Printing

Closely monitor the rst layer being printed. Most problems, like poor adhesion and

warping, will occur in the rst layer. If problems occur, stop the 3D printer in the menu or

power o the printer. Some other important tips:

• Do not leave the 3D Printer unattended while in operation

• Keep hands clear while machine is operating

• If your model is not sticking to the bed, reference page 32 to troubleshoot bed adhesion issues.

• While printing some settings can be modied. Push the dial button to access these settings:

1. Speed %: Turn the dial to adjust the print speed %. Note the original print speed is

determined by GCODE le generated, not the printer

2. Nozzle: Modify the temperature of the nozzle

3. Pause print: Pauses the print once the last instruction GCODE instruction has completed (be

patient). Tap resume print to keep printing

4. Stop print: Stops the current print

NOTE: If you change the print speed, you may need to change the nozzle temperature

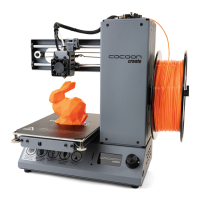

5.2 Print Times and Filament Usage

Print times and the amount of lament used per print will vary depending on many factors. Here

is an example of how size, inll, and resolution can aect printing time and lament usage. See

“Useful Terms” on page 34 for more information.

Dimensions:

62.5 x 25.75 x 67.75mm 70 x 70 x 140mm

Inll:

20% 0% 20% 20%

Resolution:

2mm 2mm 2mm 1mm

Print Time:

53min 39min 6hr 40min 13hr 12min

Filament Used:

4m 2.54m 45m 45.67m

Loading...

Loading...