253064298_201507

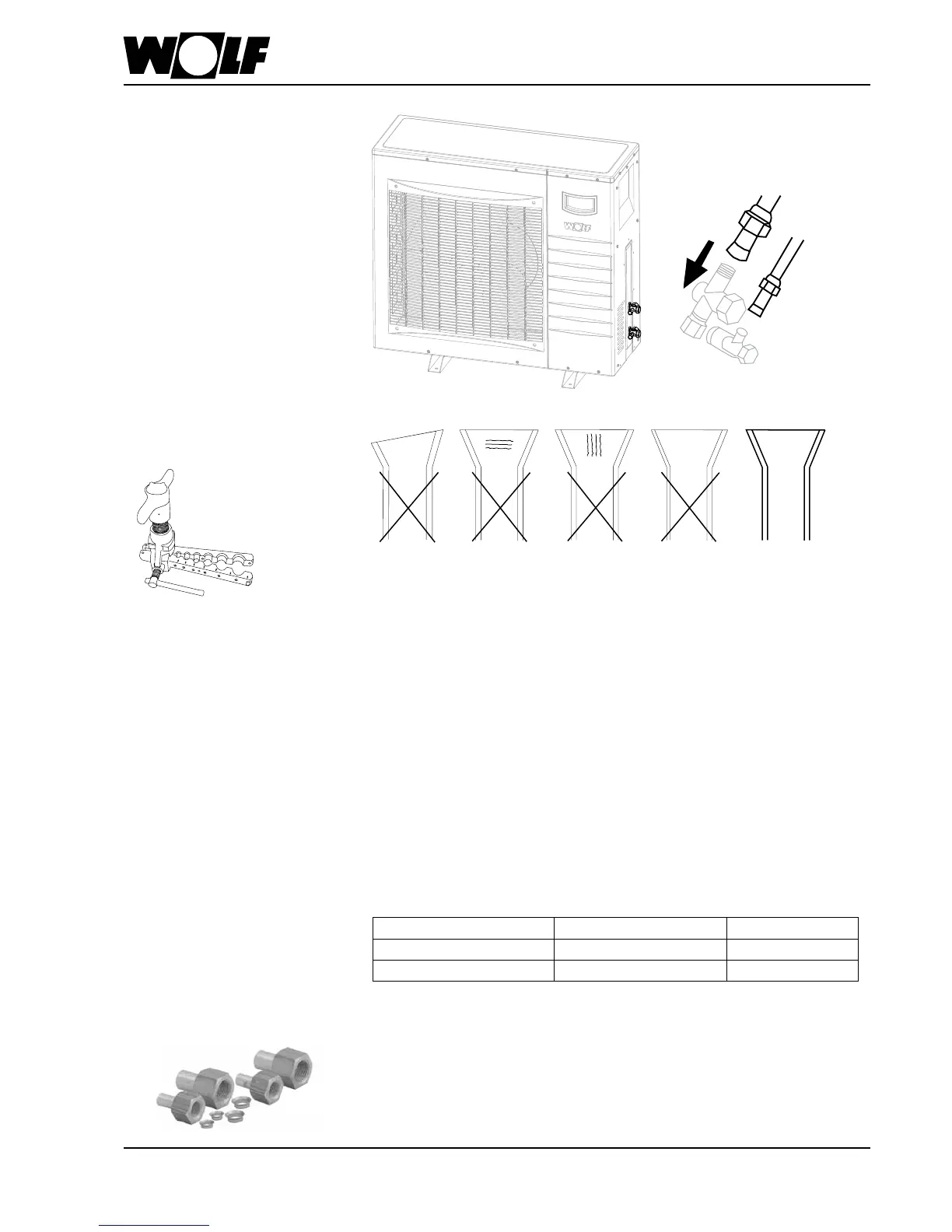

16. Connecting the refrigerant lines

to the outdoor module

Fig.:Exampleofaangingtool

Only use copper pipes which are approved for refrigerant R410A (for nominal

diameter,see"Specication"chapter).

Suction gas lines and liquid lines must have separate thermal insulation. Closed cell,

diffusion-proof thermal insulation, min. thickness 6 mm

Do not allow any contaminants (e.g. metal swarf or moisture) to enter the

copper pipes.

Remove the union nuts of the outdoor unit from connections C (liquid line) and D

(hot gas line) of the refrigerant lines.

Replace nuts with the union nuts supplied (indoor unit) (5/8 UNF for liquid line,

7/8 UNF for hot gas line).

Flare the pipe ends

Tighten the nuts

Tighten nuts with the following torque:

Line Connection to outdoor unit Torque in Nm

Liquid line Ø 10 mm 5/8 UNF 37 +/- 4

Hot gas line Ø 16 mm 7/8 UNF 70 +/- 7

Connecting the refrigerant line to

the outdoor module

Uneven

thickness

CORRECTNot level Cracks Cracks

Shapeofare

C

D

Euroangedadaptorconnectionkit

Alternatively,therefrigerantlinescanalsobeconnectedusingtheEuroanged

adapter connection kit for hard-soldering on refrigerant lines (available from the Wolf

range of accessories).

Loading...

Loading...