32 3064298_201507

20. Connecting the heating / cooling

circuit and the DHW circuit

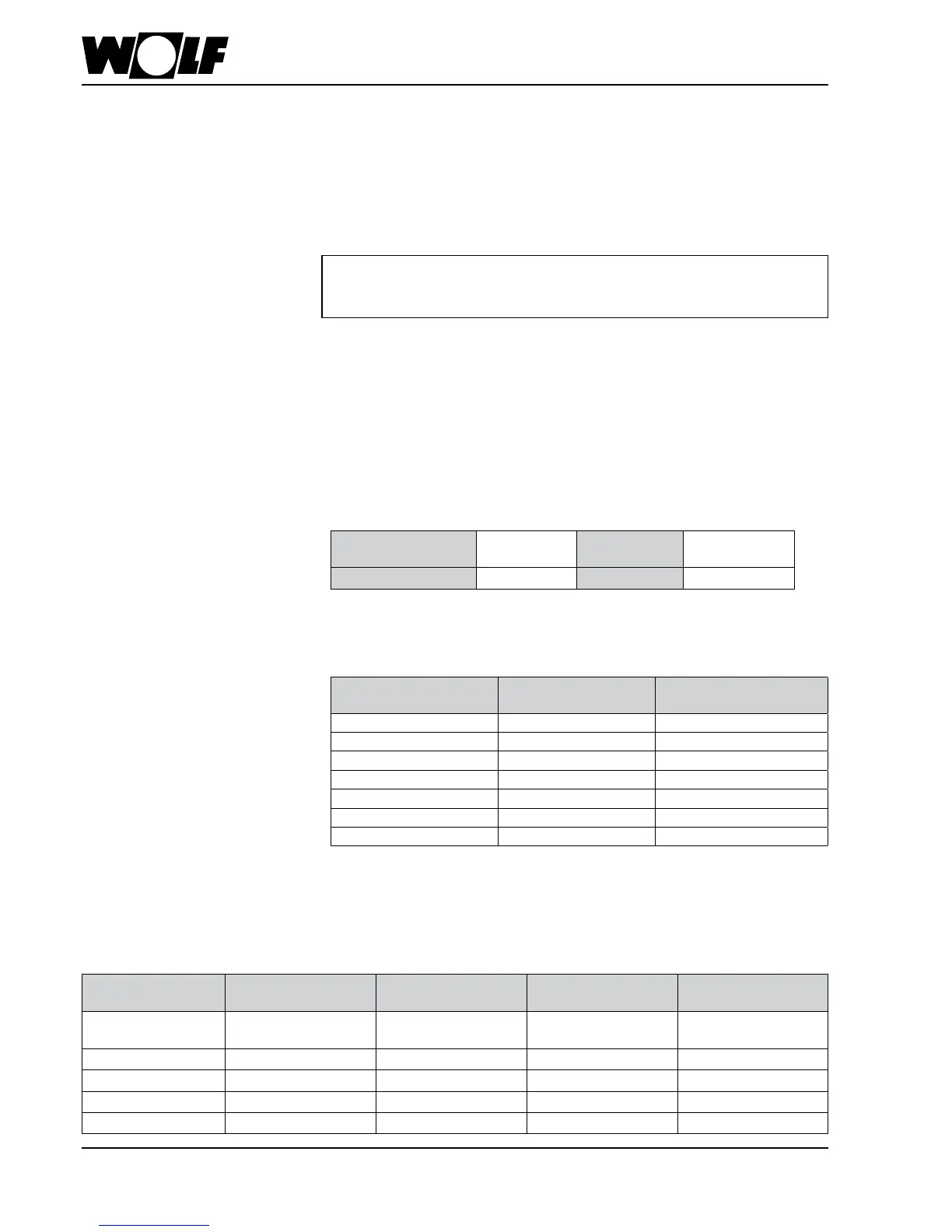

Size calculation for air/water heat pumps:

Approx. 10 litres/kW heating output (for A2/W35)

Air/water

heat pump

BWL-1S(B)-07 BWL-1S(B)-10 BWL-1S(B)-14

Buffer cylinder SPU-1-200 SPU-1-200 SPU-1-200

Recommended buffer

cylinder sizing for the

BWL-1S(B)

A buffer cylinder for optimising compressor runtime is not required, thanks to

theinvertertechnology;thereforesmallerbuffercylindersaresufcient

.

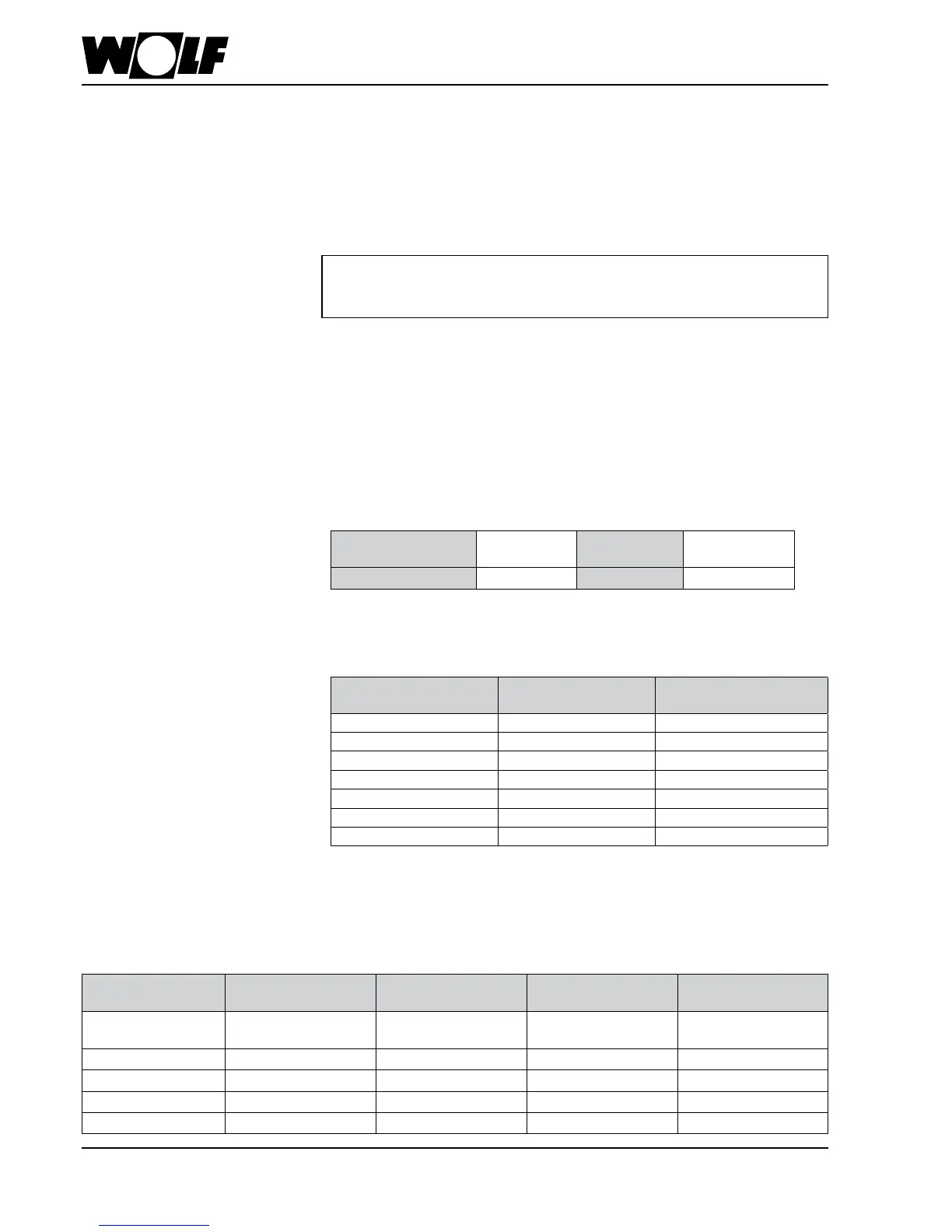

Recommended sizing for

diaphragm expansion vessel

(DEV)

Expansion vessel

size

Water content

heating system

Expansion vessel

pre-charge pressure

25 litres 235 litres 1.5 bar

35 litres 320 litres 1.5 bar

50 litres 470 litres 1.5 bar

80 litres 750 litres 1.5 bar

100 litres 850 litres 1.5 bar

140 litres 1210 litres 1.5 bar

200 litres 1600 litres 1.5 bar

Sincevariableowratescanariseontheheatdraw-offsidedependingontheload,

theminimumowratemustbeensuredtoenablefault-freeheatpumpoperation.

This is usually achieved by installing a separating buffer cylinder or a low loss header.

A buffer cylinder is essential for all systems with radiators, individual room

temperature control (thermostatic valves), multiple heat generators or heating

circuits.

For air/water heat pumps with output-dependent control in connection with 100 %

underoorheating,thereisnoneedtousea buffer cylinder, provided the following

condition is met:

1 (or more) lines of the heating system (e.g. bathroom) is permanently and fully open

(requiresthewrittenconsentoftheoperator).Forthis,theminimumowratemustbe

veriedbymeansofapressuredropcalculation.

Ifnecessary,one(ormore)heatedheatingcircuits(s)canbespecicallyopenedfully

via output A1 during defrost mode.

The valve opening time must be < 20 sec.

Buffer cylinder

Inordertoensurethattheheatpumpoperatesreliablyandefciently,itisessential

thattheowratesspeciedinthetechnicaldatafortheheatingcircuitcanbe

guaranteed. The following table lists the required minimum cross-sections for the

pipework on the heating circuit side. On systems with a separating cylinder or low

loss header, these cross-sections must, as a minimum, be observed up to the

separating cylinder (e.g. incl. the BSP/BSH) or the low loss header.

Approximate pipework

calculation for heating water

owratesandCupipeswithout

bends (observe residual head of

pump).

Air heat pump Nominalwaterowrate Minimum cross-section,

heating circuit pipework

Pressure loss

per metre

Flow velocity

BWL-1S(B)-07 19.7 l/min Pipe Ø 35x1.5 /

28x1.5

0.75 mbar/m /

2.4 mbar/m

0.41 m/s /

0.67 m/s

BWL-1S(B)-10 400V 28.8 l/min Pipe Ø 35x1.5 1.5 mbar/m 0.60 m/s

BWL-1S(B)-14 400V 34.1 l/min Pipe Ø 35x1.5 2.0 mbar/m 0.71 m/s

BWL-1S(B)-10 230 V 31,8 l/min Pipe Ø 35x1.5 1,7 mbar/m 0,66 m/s

BWL-1S(B)-14 230 V 40,4 l/min Pipe Ø 35x1.5 2,6 mbar/m 0,84 m/s

- The DHW cylinder must be equipped with an internal indirect coil suitable for the

heating output of the heat pump.

- The internal indirect coil should have a surface area of at least 0.25m² per kW of

heating output.

- Thepipeworkmustbesufcientlylarge(>DN25).

DHW cylinders

Loading...

Loading...