26

3062547_201507

19.Contractorlevelparameters

The burner switching differential regulates the burner temperature within a set range

by switching the burner ON and OFF.

The switching differential between burner stage 1 and burner stage 2 is always half

the switching differential.

See also parameter HG31 diagram.

Burner switching differential

Parameter HG01

HG01

10

Factory setting: 10 K

Setting range: 1 to 20 K

This parameter shifts the minimum and maximum fan speed parallel downwards or

upwards.

This enables the CO

2

value for burner stages 1 and 2 to be adjusted at the same

time. See also chapter 22 "CO

2

adjustment by matching the pipe lengths"

One unit = 120 r.p.m

Setting 3 = set value, burner control unit

Matching the pipe length

Parameter HG00

HG00

3

Factory setting: 3

Setting range: 1 to 5

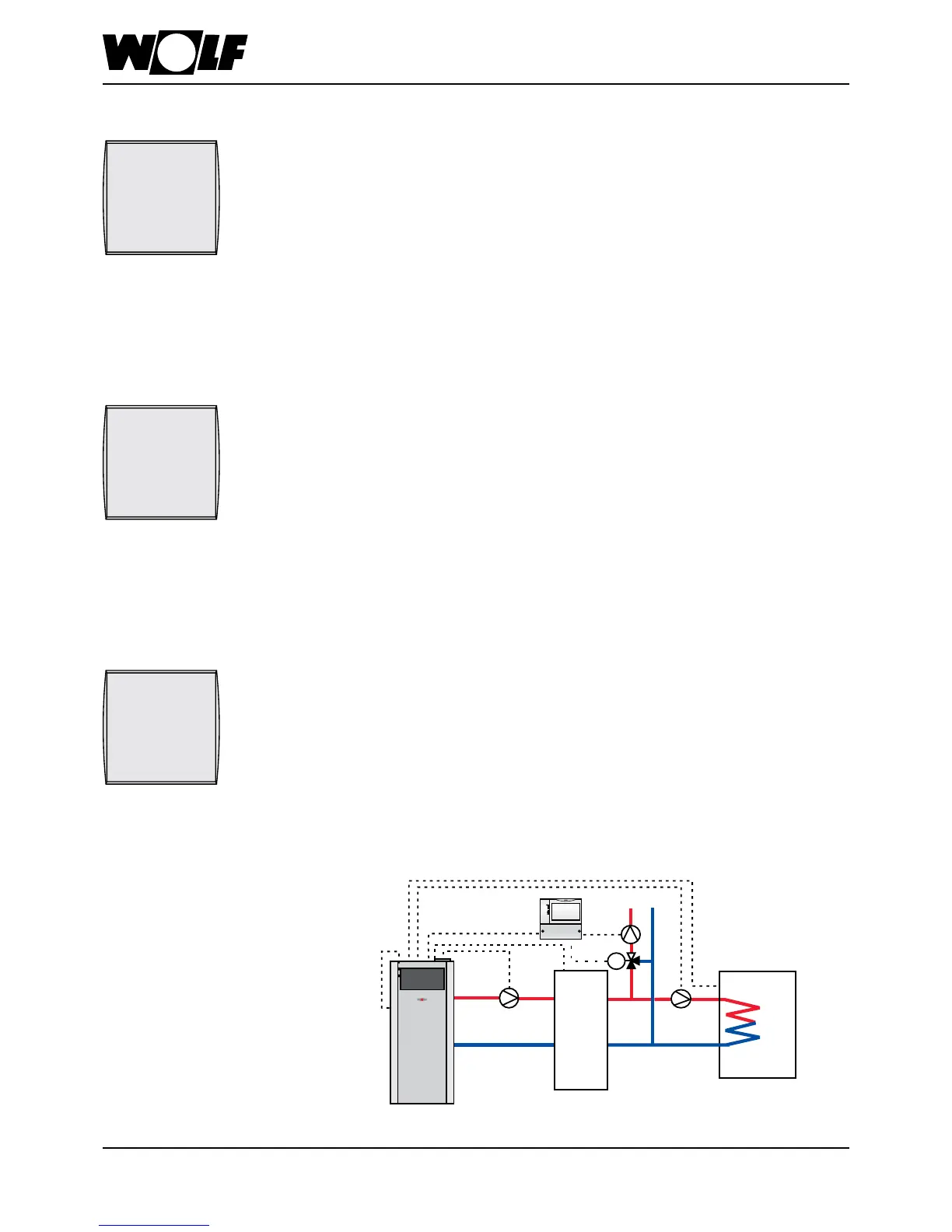

Pump operating mode 0:

Heatingcircuitpumpforheatingsystemswithoutcascadecontrolandwithout

low loss header

The heating circuit pump runs constantly when there is a heat demand. The heating

circuit pump will be switched OFF during cylinder heating if DHW priority has been

selected.

Pump operating mode 1:

Feedpumpforheatingsystemswithcascadecontroland/orlowlossheader

Heating circuit pump becomes the feed pump.

The header sensor affects the heating operation as well as cylinder heating. The feed

pump runs only when there is a burner demand. Pump run-on in accordance with

parameter HG07.

Hydraulic scheme:

Pump operating mode

Parameter HG06

HG06

0

Factory setting: 0

Setting range: 0 / 1 / 2

ZUP = Feed pump

SPL = Cylinder primary pump

SF = Cylinder sensor

SAF = Header sensor

KF = Boiler sensor

MKP = Mixer circuit pump

M = Mixer motor

MM = Mixer module

Oil condensing boiler

Cylinder

Low loss

header or

buffer

M

MM

SAF

ZUP

MKP

SPL

SF

KF

Loading...

Loading...