34

3062547_201507

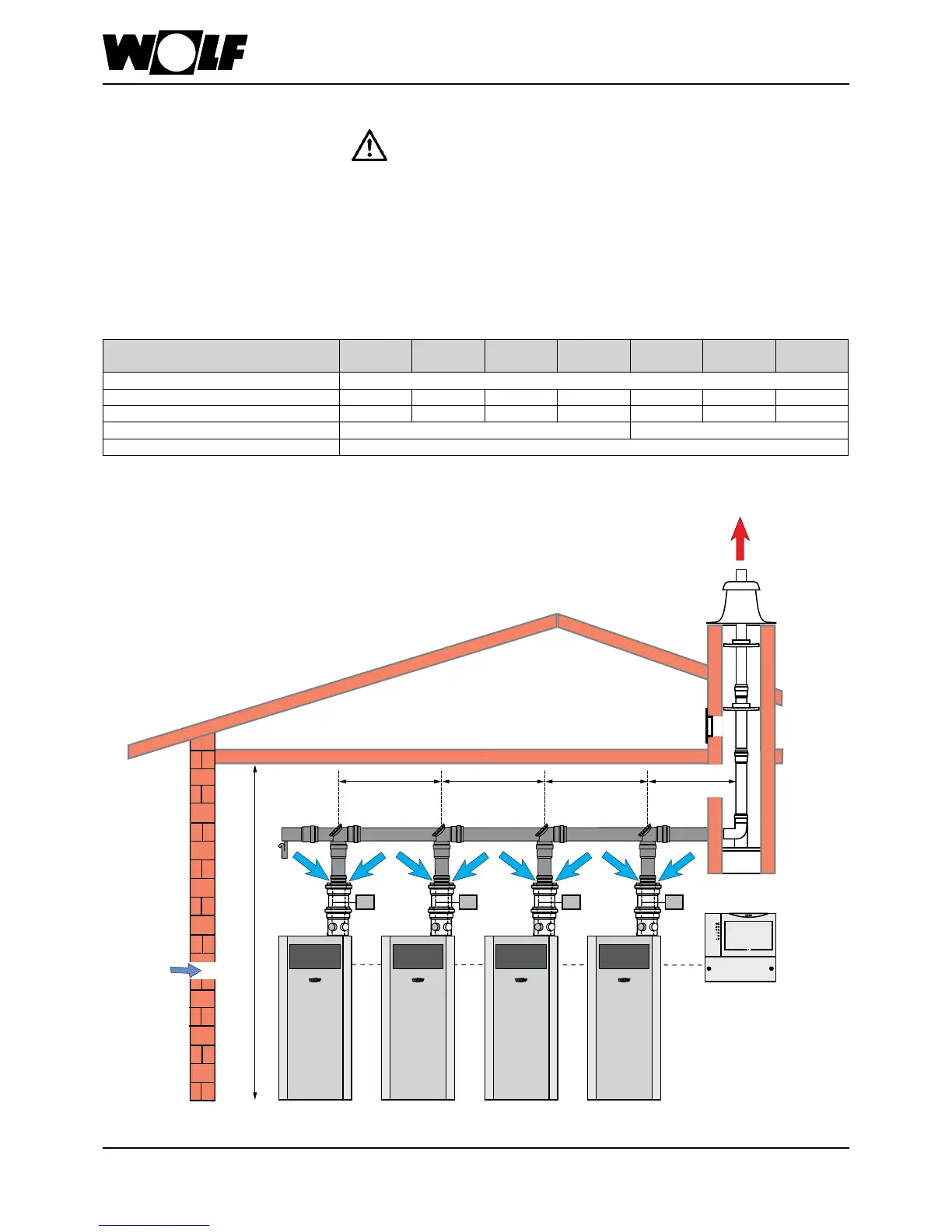

22. Cascade operation

Flue gas header design

For open ue operation, there must be an aperture in the boiler room that opens to

the outside and has a clear cross-section of at least 150 cm².

Where necessary, adapt the installation examples to the relevant Building Regulations

and requirements of your country/region. Discuss any questions relating to the

installation, particularly of inspectioncoversandventilationapertures(ventilation

generallyrequiredabove50kWoutput)with your local heating engineer.

Flue gas routing with header

Oil condensing boilers with common ue routing - open ue operation in installation

type B23.

Number

2 x

COB-29

2 x

COB-29

3 x

COB-29

4 x

COB-29

2 x

COB-40

3 x

COB-40

4 x

COB-40

Installation Art B23

Flue internal diameter DN110 DN160 DN160 DN160 DN160 DN160 DN160

Total ue gas mass ow rate g/s 26.6 26.6 40.0 53.3 35.0 52.5 70.0

Max. ue gas temperature °C 76 83

Max. effective building height

m 30

Cascade control with header

DWTK

min. 600

max. 1000

KM module

Flue cascades are only suitable in balanced ue operation. They must be designed to

EN 13984-1.

To prevent ue gas escaping, a ue cascade is only permitted with a tested

ue gas damper.

Flue cascade

Ceiling height at least 2500 mm

The effective heights specied are only valid on the condition that the length of the ue between the individual appliances and

downstream of the last appliance does not exceed 2 m. 325 m was assumed as the geodetic height. If the conditions at the

installation site are different, an individual calculation is required.

Loading...

Loading...