42

3062547_201507

28. Commissioning without Wolf control

accessories(BM)

0

I

0

°C

20

40

60

80

100

120

ON/OFF

switch

Heating water

temperature

selector

DHW

temperature

selector

Commissioning

Only qualified personnel must carry out the commissioning and

operationoftheboiler,aswellasinstructtheuser.

- Remove front and top casing.

- Pivot the control unit downwards.

- Insert the oil pressure gauge into the pump's pressure gauge test port.

- Remove the cap from the l.h. "ue gas" test port.

- Insert the test probe of the CO

2

measuring instrument into the "ue gas" test port.

(approx. 70 mm).

- Turn the heating water temperature selector to "Emissions test"

(illuminated signal ring as status indicator ashes yellow.)

- Measure the CO

2

content and compare it against the values given in the stage 2

table adjacent.

- If required, set the CO

2

content with the stage 2 pressure regulating screw using a

4 mm Allen key in accordance with the table.

Turn clockwise - higher CO

2

value

Turn anti-clockwise - lower CO

2

value

CO

2

settingsvia

pump pressure

IfnocontrolaccessoryisconnectedtotheapplianceortheCO

2

setvalueisnot

achievedbymatchingthepipelengths,thesettingismadeviapumppressure

control:

"Inlet air"

test port

"Flue gas"

test port

- Checktheboilerandsystemforleaks.Normaloperatingpressure

whensystemiscold1.5-2.0bar.Preventwaterleaks.

- Check location and seating of the installation.

- Checkthefuellevelintheoiltank.

-

Check all connections and component links for leaks.

-

If tightness cannot be ensured then there is a danger of water damage.

NB

- Fit casing.

- Check that all ue gas accessories have been correctly installed.

- Open the shut-off valves on ow and return.

- Open oil shut-off valves (tank, oil line, lter).

- Switch ON the heating system emergency stop switch.

- Switch ON the system ON/OFF switch on the control unit.

- Remove cap from r.h. test port (inlet air).

- Insert test probe 2 cm.

- Turn DHW temperature selector to 1.

- Turn heating water temperature selector to "Emissions test"

(illuminated signal ring ashes yellow).

- After a pre-purge time of approx. 25 seconds, the pump starts up and opens the

solenoid valve. The supplied fuel oil reaches the nozzle and a ame is established.

- The burner enters a fault state if, during commissioning, the oil pump does not supply

sufcient oil during the pre-purge time. Repeat the burner start by pressing reset.

- Measure temperature and CO

2

in the inlet air and enter the values in the commissioning

report in chapter 24.

- The ue is not gas tight if the CO

2

content > 0.2%; rectify the leak.

- Terminate the emissions test mode by turning the temperature selector back to its

original position.

- If emissions test mode is not reset manually, the appliance switches back to the

original operating mode automatically after 15 minutes.

- Remove the test probe and close the test port. Ensure the cap is seated rmly.

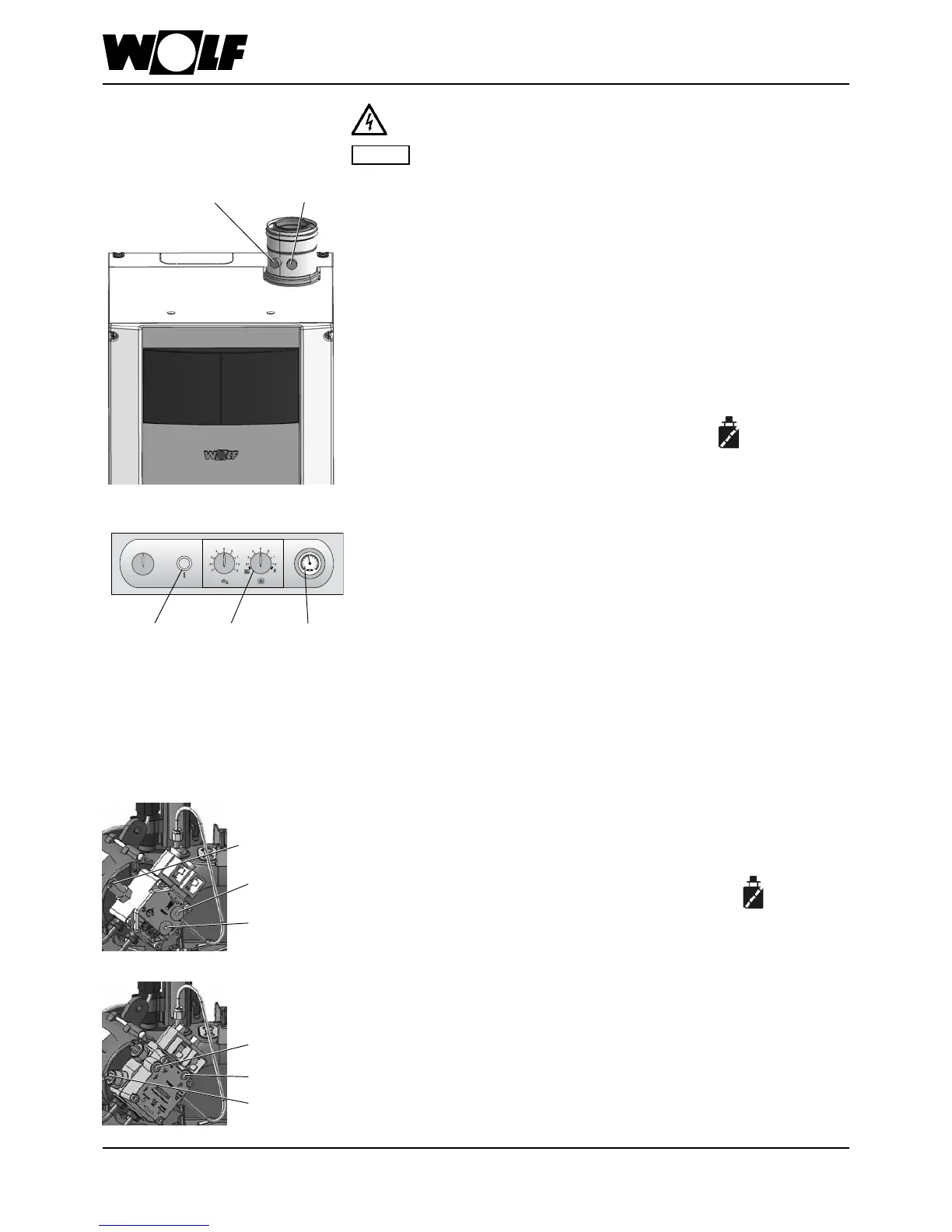

AdjustingtheCO

2

valueinthe

upperloadrange(stage2)

(emissionstestmode)

Vacuum test

connection

Vacuum test

connection

Oil pressure

test connection

Oil pressure

test connection

Pressure regulating

screw, stage 2

Pressure regulating

screw, stage 2

Pump Danfoss

Pump Suntec

Loading...

Loading...