7

3062547_201507

* These nozzles comply with the emission requirements according to RAL-UZ 46 and ensure reliable operation. No other nozzles are permissible!

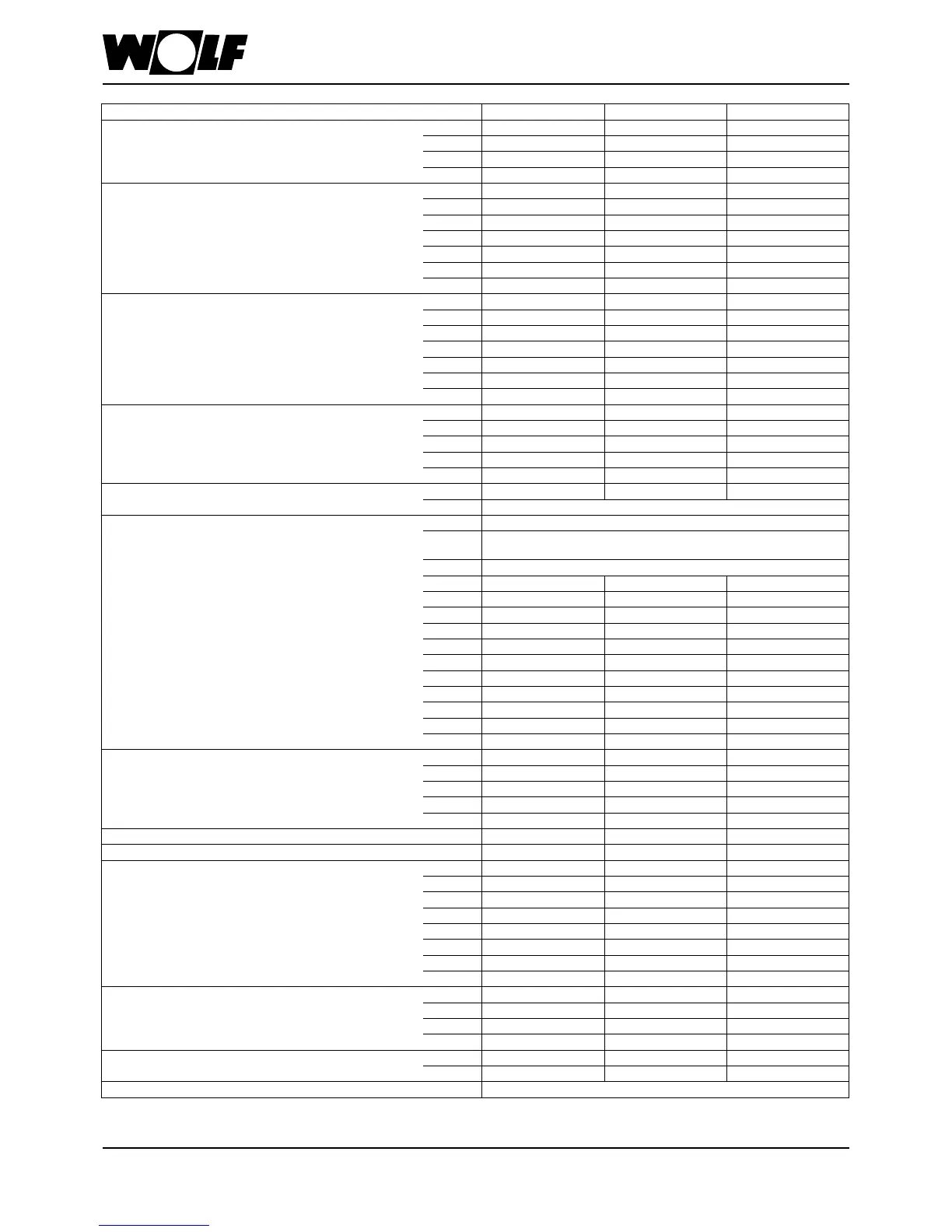

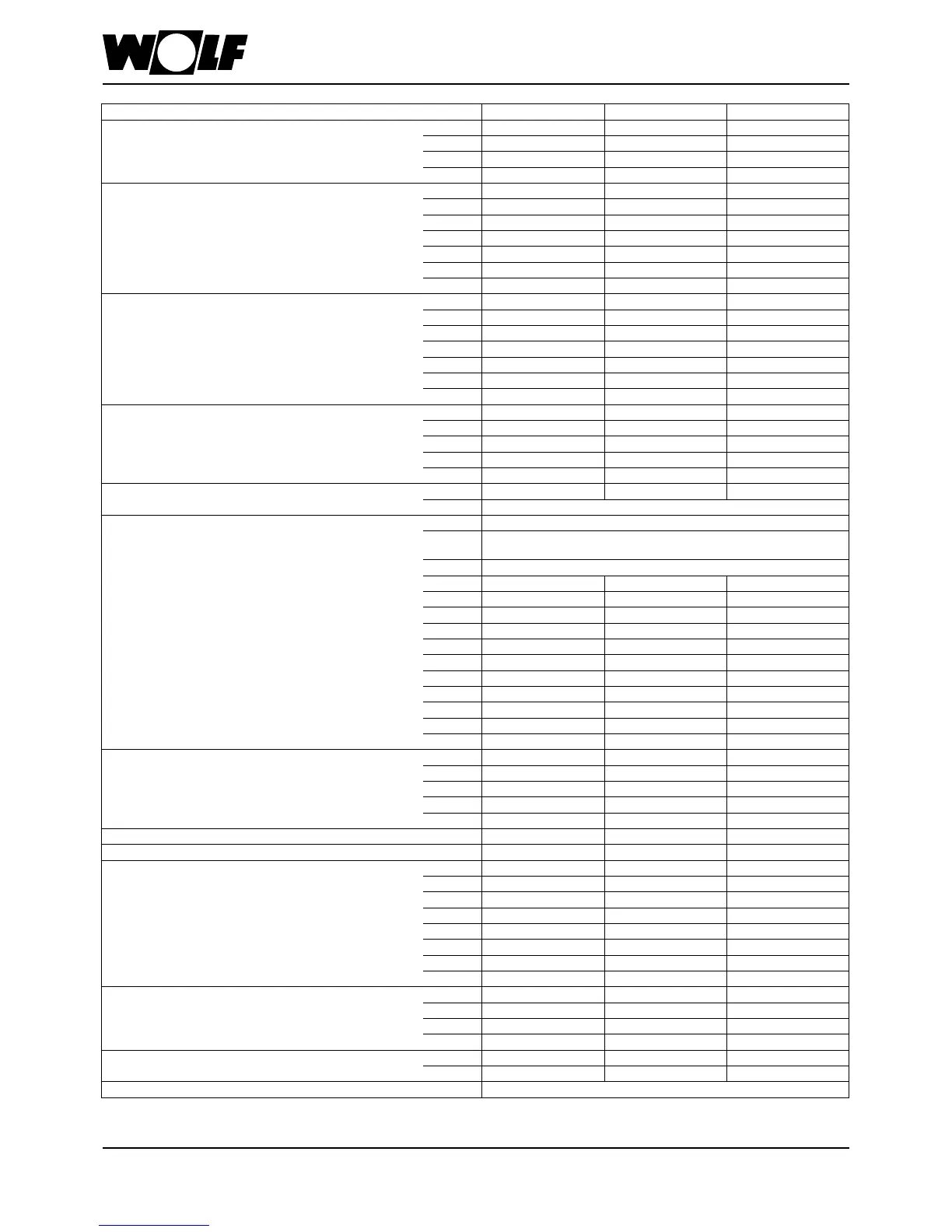

Oil condensing boiler COB-29 COB-29/TS COB-40

Rated output at 80/60 °C, stage 1/2 kW 18,5 / 28,2 18,5 / 28,2 25,3 / 38,0

Rated output at 50/30 °C, stage 1/2 kW 19,6 / 29,6 19,6 / 29,6 26,8 / 40,0

Rated load, stage 1/2 kW 19,0 / 29,0 19,0 / 29,0 26,0 / 38,8

Oil throughput, stage 1/2 kg/h 1,60 / 2,45 1,60 / 2,45 2,44 / 3,64

Rated capacity TS (equivalent) Ltr - 160 (260) -

Constant cylinder output TS kW/Ltr/h - 29 / 710 -

Performance factor TS NL60 - 5,0 -

DHW output TS l/10min - 300 -

Standby input TS kWh/24h - 1,47 -

Max. permissible cold water supply pressure TS bar - 10 -

Minimum anode current, protective magnesium anode mA - > 0,3 -

External diameter, heating ow G 1½" 1½" 1½"

External diameter, heating return G 1½" 1½" 1½"

Condensate connection 1" 1" 1"

Oil connection, ow/return hoses G 3/8" 3/8" 3/8"

Cold water inlet G - 3/4" -

DHW connection G - 3/4" -

DHW circulation connection G - 3/4" -

Height mm 1290 1290 1490

Width mm 566 1132 566

Depth mm 605 605 605

Boiler weight kg 99 99 122

Cylinder weight kg - 76 -

Balanced ue connection mm 80/125 80/125 110/160

Balanced ue routing Type B23, B33, C33(x), C43(x), C53(x), C63(x), C83(x), C93(x)

Fuel oil Fuel oil EL, low sulphur, bio-oil B10 or fuel oil EL standard

Nozzle* Danfoss 0,55 / 80° S LE

Fuel oil lter Siku max, 40 μm

CO

2

setting stage 1 and stage 2 % 13,5 ± 0,3 13,5 ± 0,3 13,5 ± 0,3

Pump pressure stage 1 bar 8,5 ± 1 8,5 ± 1 11,0 ± 1,0

Pump pressure stage 2 bar 16,8 ± 2,5 16,8 ± 2,5 23,5 ± 2,5

Maximum negative pressure in oil lines bar -0,3 -0,3 -0,3

Flow temperature, factory setting °C 80 80 80

Max. ow temperature °C 85 85 85

Heating water pressure drop at Δ T=20 K mbar 17 17 54

Heating water pressure drop at Δ T=10 K mbar 55 55 205

Max. permissible boiler pressure bar 3 3 3

Heating surface, heating water heat exchanger m² 3,05 3,05 3,85

Heat exchanger water content Ltr. 9,0 9,0 11,5

Seasonal efciency [to DIN] at 40/30 °C (H

i

/ H

s

) % 105 / 99 105 / 99 104 / 98

Seasonal efciency [to DIN] at 75/60 °C (H

i

/ H

s

) % 101 / 96 101 / 96 98 / 93

Efciency at rated load at 80/60 °C (H

i

/ H

s

) % 97 / 92 97 / 92 98 / 93

Efciency at 30% partial load and TR=30 °C (H

i

/ H

s

) % 103 / 97 103 / 97 103 / 97

Boiler standby loss qB at 70 °C (EnEV) % 0,55 0,55 0,45

SEDBUK

band A A A

SAP 2009 annual efciency

% 91.4 91.4 91.4

Rated heat input (stage 2):

Flue gas mass ow rate g/s 13,33 13,33 17,51

Flue gas temperature 50/30 - 80/60 °C °C 55 - 76 55 - 76 56 - 83

Available fan draught Pa 105 105 150

Lowest heat input (stage 1):

Flue gas mass ow rate g/s 9,05 9,05 10,91

Flue gas temperature 50/30 - 80/60 °C °C 40 - 64 40 - 64 43 - 68

Available fan draught Pa 55 55 72

Electrical connection V~/Hz 230/50 230/50 230/50

Integral fuse (medium slow) A 5 A 5 A 5 A

Power consumption, stage 1 / stage 2 W 129 / 178 129 / 178 126 / 205

Protection IP20 IP20 IP20

Condensate volume at 40/30 °C Ltr./h 2,2 2,2 2,8

Condensate pH value approx, 3 approx, 3 approx, 3

CE ID CE-0085BS0326

3.Specication

Loading...

Loading...