32

3062547_201507

SettingtheeBUSaddressfor

cascade mode

(seeinstallationinstructionsfor

KMmodule)

The eBUS address is set by pressing the reset button for at least 5 seconds after

the appliance has been switched on. After 5 seconds, the corresponding ashing

code appears (in accordance with the table) at the illuminated signal ring. Select the

corresponding eBUS address with the DHW temperature rotary selector. Your selection

of the required eBUS address is saved by releasing the reset button. No address can

be allocated more than once.

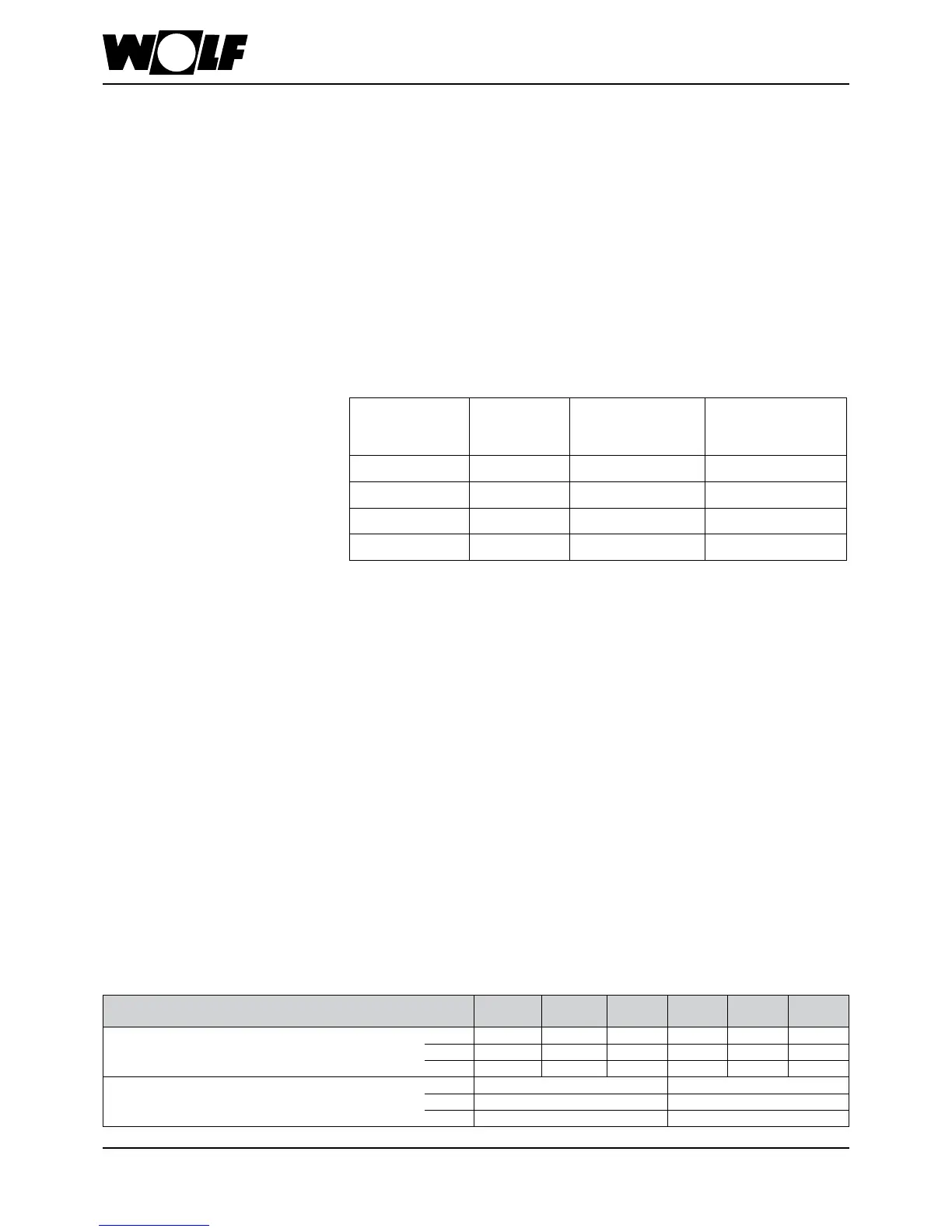

20. Cascade operation

Control/specication/notes

Cascadetype

2 x

COB-29

3 x

COB-29

4 x

COB-29

2 x

COB-40

3 x

COB-40

4 x

COB-40

Rated output at 80/60 °C

kW 56.4 84.6 112.8 76.0 114.0 152.0

Rated output at 50/30 °C kW 59.2 88.8 118.4 80.0 120.0 160.0

Rated heat input

kW 58.0 87.0 116.0 77.6 116.4 155.2

Lowest output at 80/60 °C Stage 1

kW 18.5 25.3

Lowest output at 50/30 °C Stage 1 kW 19.6 26.8

Lowest output

kW 19.0 26.0

Specication

Heating circuit

To ensure the heating water ow rate through every condensing boiler is as even as

possible, the following connection types are recommended:

1. For precise hydraulic balancing, a line regulating valve can be tted in the supply

line to every appliance.

2. Design the ow and return lines with the same length for the ow and return according

to the Tichelmann system, to ensure the pressure drop in every line is equally high.

These oil condensing boilers have control PCBs with functions that are optimally

matched to the digital controller type KM for cascade control. Up to four COB-29

or COB-40 oil condensing boilers (with the same output) with an output range of

18.5 kW to 112.8 kW (cascade COB-29) or 25.3 kW to 152.0 kW (cascade COB-40)

can be linked together to form a single cascade. Subject to load, this digital cascade

controller KM can control the header ow, a mixer circuit and a DHW cylinder circuit.

The digital controller type MM from the WOLF range of control accessories can be

connected to regulate an additional mixer circuit and radiator circuit. Furthermore, a

BM can be used in each case as a remote control.

For a detailed description, see also the installation instructions for the individual modules.

General

Low loss header

It must not be possible for the on-site heating circuit pumps or primary pumps to inuence

the function of the condensing boilers. A low loss header should therefore be installed

upstream of the heating water circuit or DHW cylinder circuit. Furthermore, ensure that

the heating water ow rate through the condensing boilers is set lower than that through

the subsequent heating circuit. The ow rate should therefore be set upstream of the low

loss header via a line regulating valve or buttery valve.

Systemseparation

Instead of the low loss header, a heat exchanger can be installed. If pipes are used which

are not impermeable to oxygen, this is a requirement in any case.

DHWcylinder

A DHW cylinder is generally connected downstream of the system separation (e.g. via

a low loss header).

Cylinder heating is controlled via the cascade controller type KM, to which a cylinder

primary pump and the electronic cylinder sensor are connected.

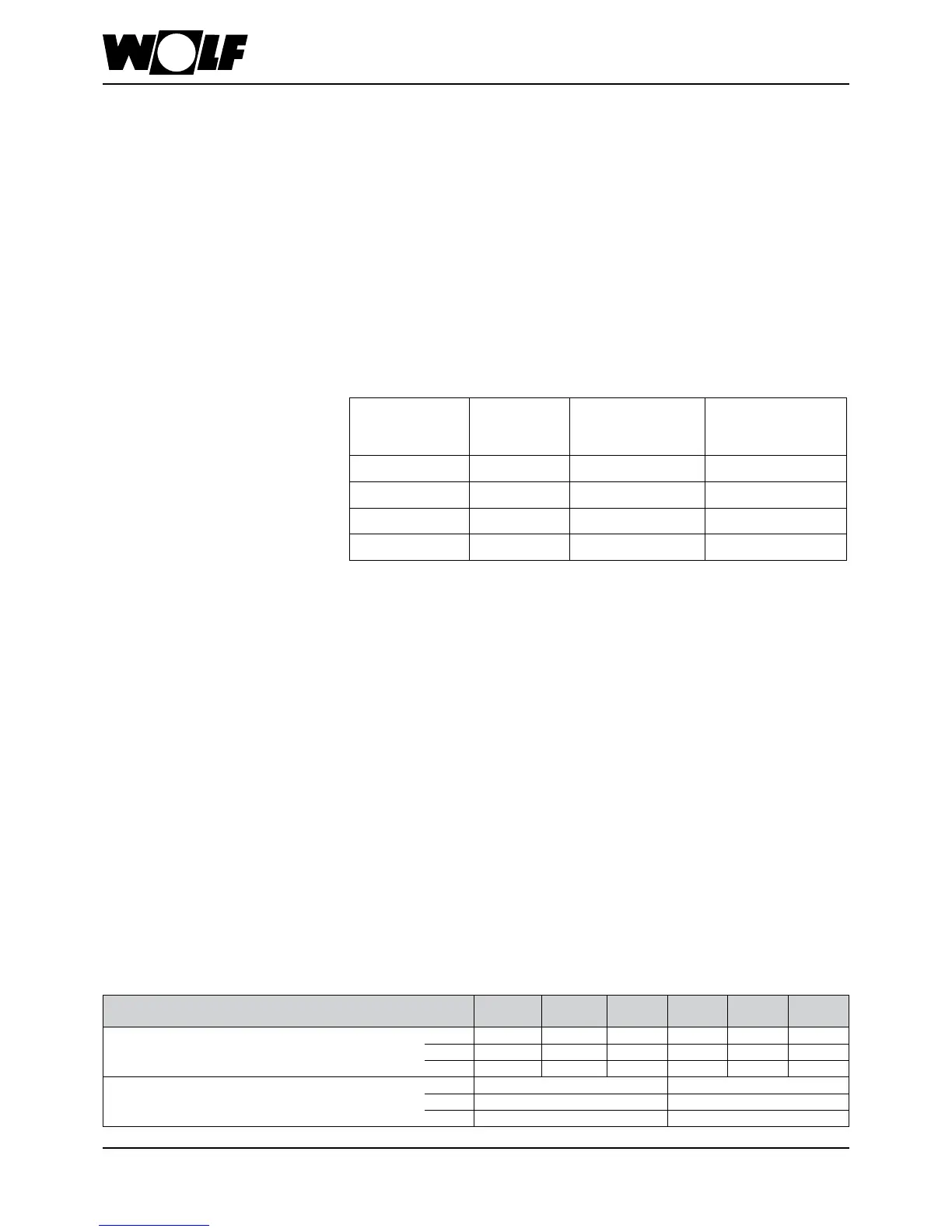

*Factory setting (individual boiler without cascade mode)

Boiler in cascade

operation

eBUS

address

Rotaryselector,

DHW temperature

selection

Illuminated signal

ring indication

Boiler 1 1* 1* ashing red

Boiler 2 2 2 ashing yellow

Boiler 3 3 3 ashing yellow/red

Boiler 4 4 4 ashing yellow/green

Loading...

Loading...