41

3062547_201507

- Measure the ue gas, CO

2

content, ue gas temperature and soot value and enter

them in the commissioning report (chapter 29).

- Modifying the parameter HG00 has also adjusted the speed for stage 1. For checking

purposes, the boiler must be set to stage 1.

- Switch HG28 burner operating mode from 2 (two-stage) to 1 (single stage).

- Measure the CO

2

content and compare it against the values given in the stage 1

table adjacent.

- If the value is outside the set value, the CO

2

value must be adjusted via the pump

pressure (see chapter 28 "Commissioning without Wolf control accessories").

- Reset HG28 burner operating mode from 1 to 2.

- Terminate the emissions test mode by turning the program selector switch on the

BM programming module to the required operating mode. If emissions test mode

is not reset manually, the appliance switches back to the original operating mode

automatically after 15 minutes.

- Remove the test probe and close the test port.

27. CO

2

check/adjustmentbymatching

the pipe lengths

CO

2

adjustmentby

matching the pipe

lengths

WithcontractorparameterHG00(seechapter19"Contractorlevelparameters"),

theappliancescanbematchedtotheuegassystembychangingthespeed

for both stages.

- The casing must be closed for this setting.

- Remove the cap from the l.h. "ue gas" test port.

- Insert the test probe of the CO

2

measuring instrument into the "ue gas" test port

(approx. 70 mm).

- Turn the program selector switch on BM module to "Emissions test". (Illuminated

signal ring as status indicator ashes yellow.)

- Measure the CO

2

content and compare it against the values given in the Stage 2

table adjacent.

- If required, alter the CO

2

content with parameter HG00.

Completingtheadjustments

- Check the control parameters and match them to the system if necessary.

- Check the condensate drain.

- Instruct the customer in the operation of the boiler, with the aid of the operating

instructions.

- Complete the commissioning report (chapter 29) and hand over the instructions to

the customer.

- Instruct the customer about the need for annual servicing.

- Instruct the customer about energy saving options.

- Refer your customer to section "Information regarding energy efcient operation" in

the operating instructions.

CO

2

check in the lower load

(stage1)

CO

2

setvalue,boilerclosedstage1

13.5 ± 0.3%

AdjustingtheCO

2

valueinthe

upperloadrange(stage2)

(emissionstestmode)

CO

2

setvalue,boilerclosedstage2

13.5 ± 0.3%

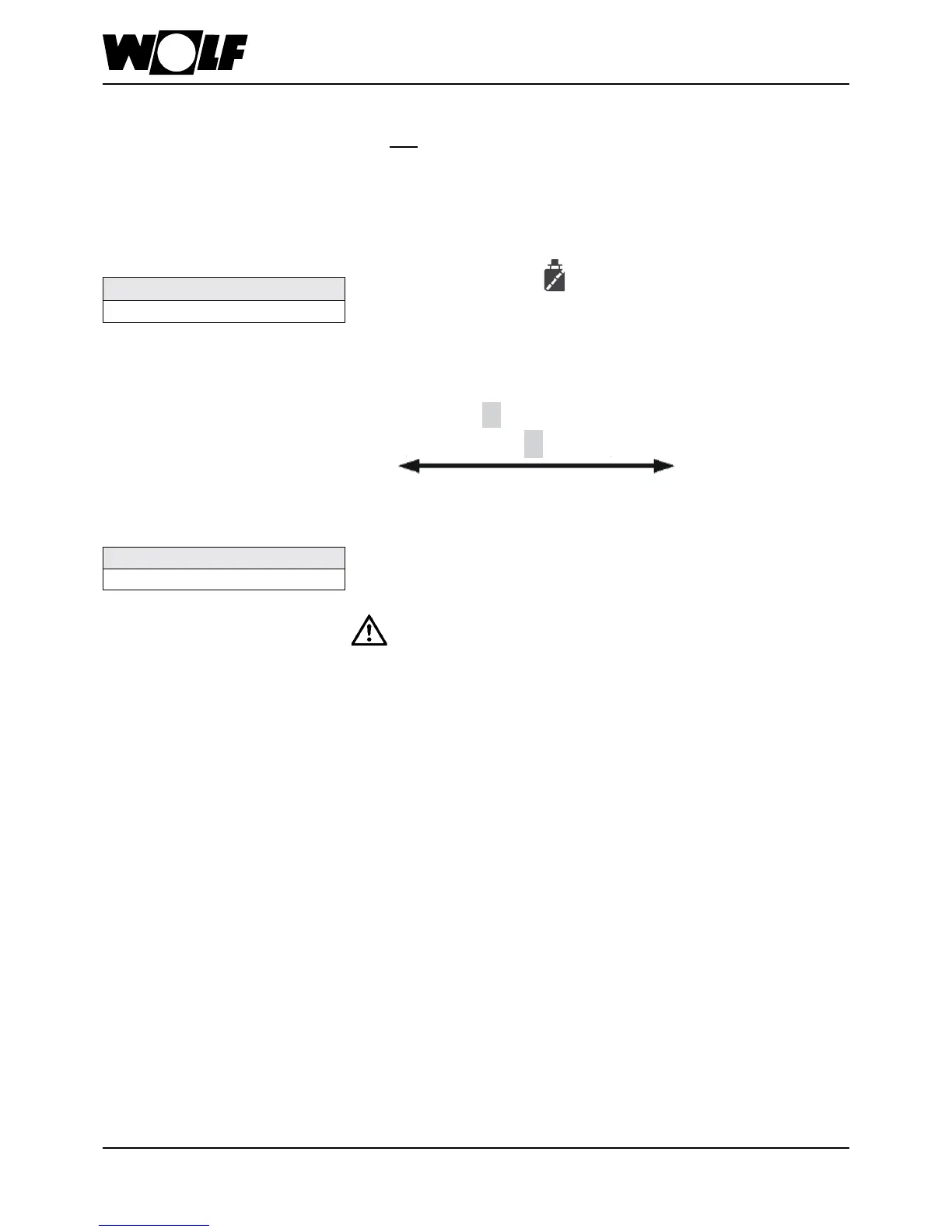

HG 00 CO

2

settings

Factory setting: 3

1 2 3 4

5

Lower CO

2

valueHigher CO

2

value

Loading...

Loading...