en - Original instructions

e-SV series - Installation, Operation and Maintenance Manual 21

8. Install a pressure gauge (or a vacuum pressure gauge, in case of suction lift installation) on

the suction side, and a pressure gauge on the discharge side, for checking the actual

operating pressure of the pump unit.

9. To exclude the unit from the system for the purpose of maintenance, install:

An on-off valve on the suction side

An on-off valve on the discharge side, downstream the check valve and pressure gauge,

also useful for regulating the flow rate.

10. On the suction side, install a device to prevent the absence of liquid (float or probes), or a

minimum pressure device.

11. Sufficiently submerge the end of the suction pipe in the liquid, in order to prevent any air

from penetrating through the suction vortex when the level is at the minimum

12. In case of suction lift installation, the suction pipe must have an increasing slope towards

the unit exceeding 2%; to avoid air pockets; also install:

A foot check valve that guarantees full opening (full section)

A filling on-off valve to facilitate the removal of the air and priming.

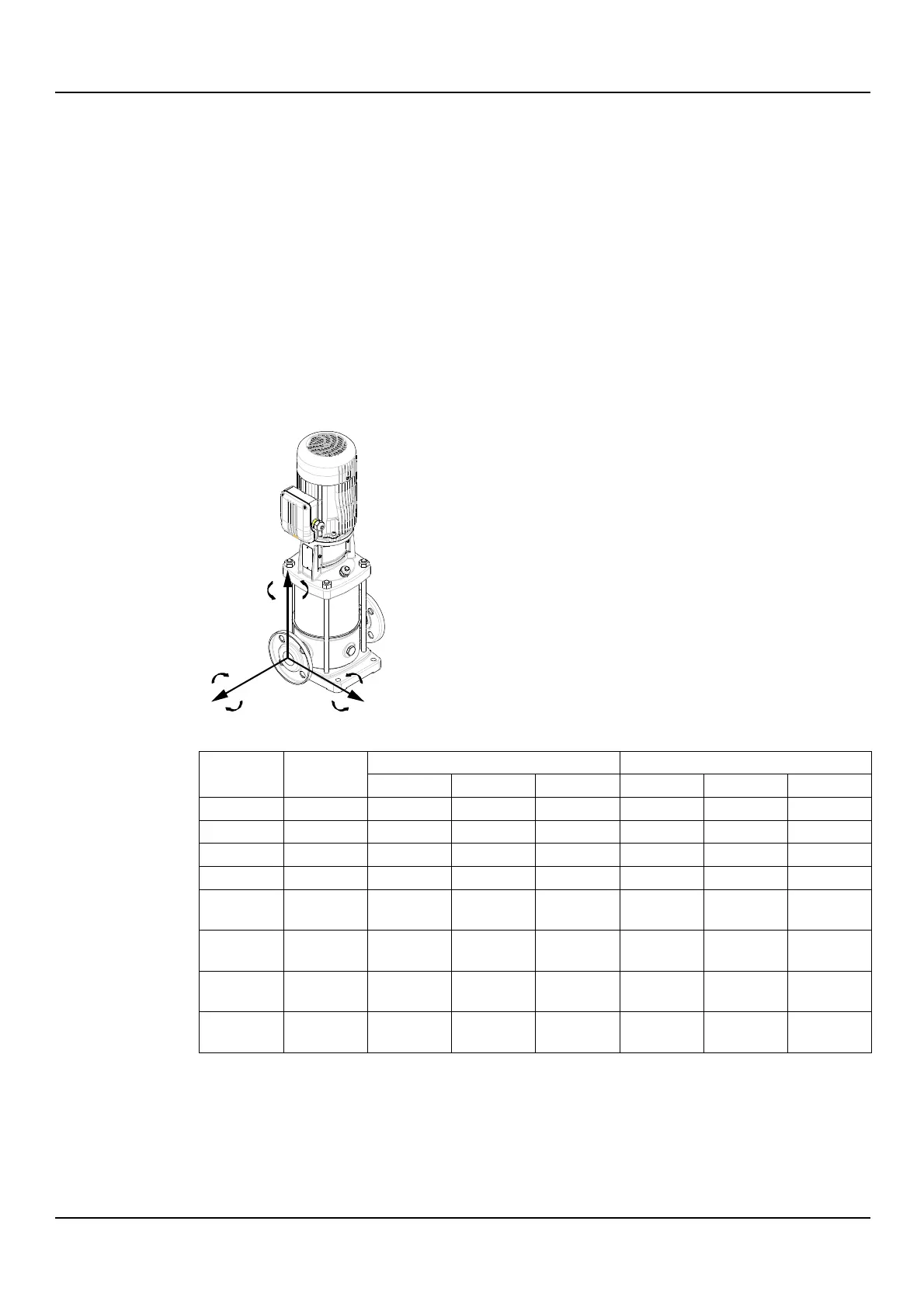

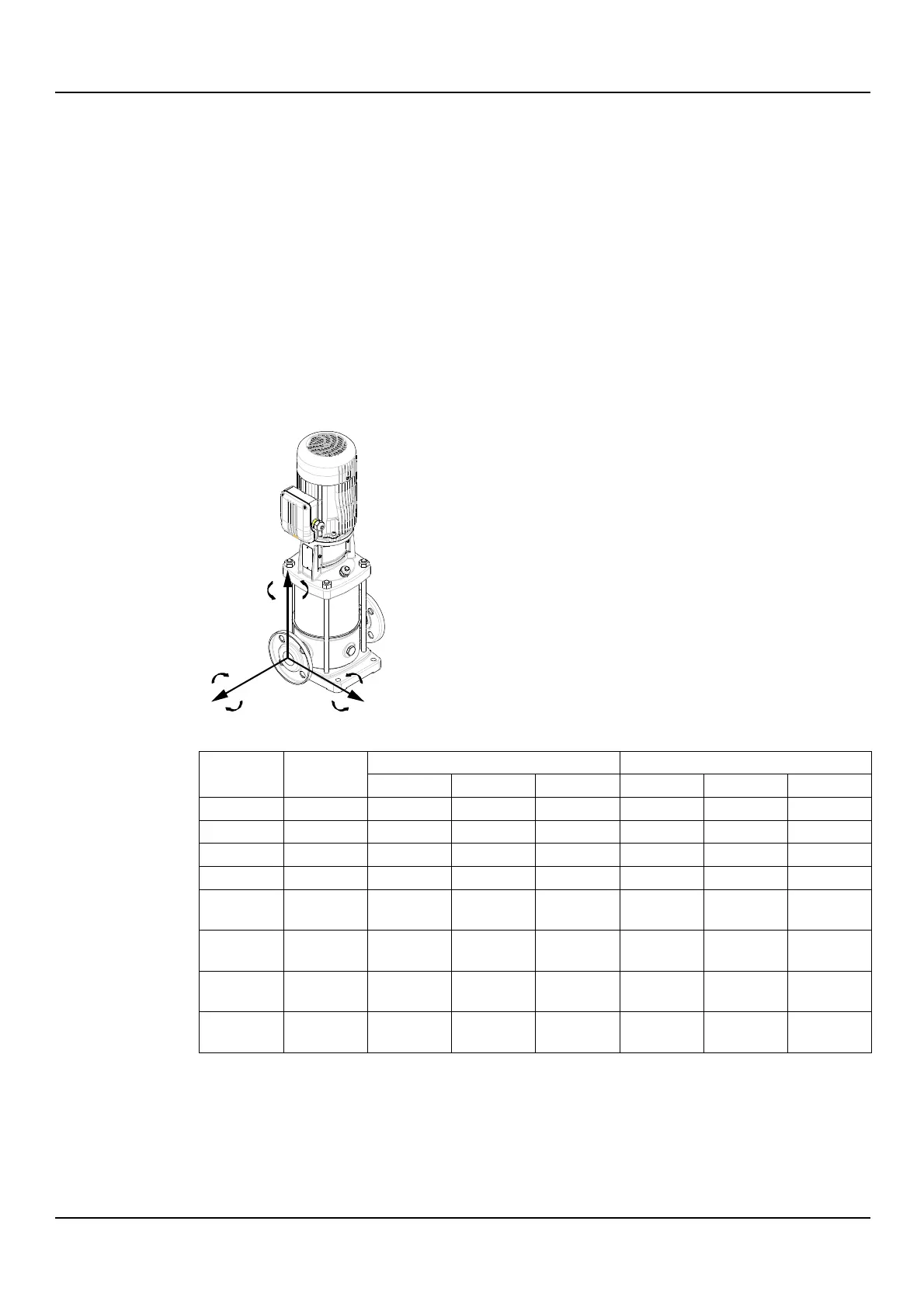

4.3.2 Flange forces and torques

Figure 13: Flange forces and torques

ESV_M0014_A_sc

Mz

Mx

My

Fy

Fz

Fx

y

x

z

Loading...

Loading...