Brush and Commutator Inspection

HYDRAULIC PUMP MOTOR AND

TRACTION MOTOR

NOTE: When inspecting brush conditions and motor

commutator conditions for head damage or abnormal

wear, the battery maintenance and condition should

be eliminated as a cause first. See Industrial Battery

2240YRM0001.

NOTE: The brushes and commutator can be inspec-

ted, the brushes can be replaced, and Stoning the

Commutator can be done with the motor installed in

the truck.

NOTE: Inspect the brushes and commutator every

350 hours for best operation and to prevent motor

damage. The hydraulic pump motor normally has

more start cycles than other motors, so it can have

more wear and possible damage.

NOTE: The following procedure is for inspecting the

brushes and commutator with the motor installed in

the lift truck. The same inspections can be done with

the motor removed. If the motor is removed, start at

Step 3.

1. To rotate the commutator of the traction motor

without moving the truck, the drive wheels must

be raised. See Figure 1. Raise drive wheels so

commutator of the traction motor can be rotated

without moving lift truck. See How To Raise

Drive Wheels in the Operating Manual or the

Periodic MaintenanceYRM section for your lift

truck.

NOTE: For some models of lift trucks, the battery

does not need to be removed to access the electric

motors. Other models will require the removal of the

battery before gaining access to the electric motors.

To remove the battery, either raise the hood panels or

unfasten the floor plate, depending on which motor

needs to be accessed.

2. Remove battery. See How to Remove Battery in

the Operating Manual or the Periodic Mainte-

nanceYRM section for your lift truck. Remove ac-

cess plate to motors. If the battery in your lift truck

does not need removal for access to the motors,

go to Step 3.

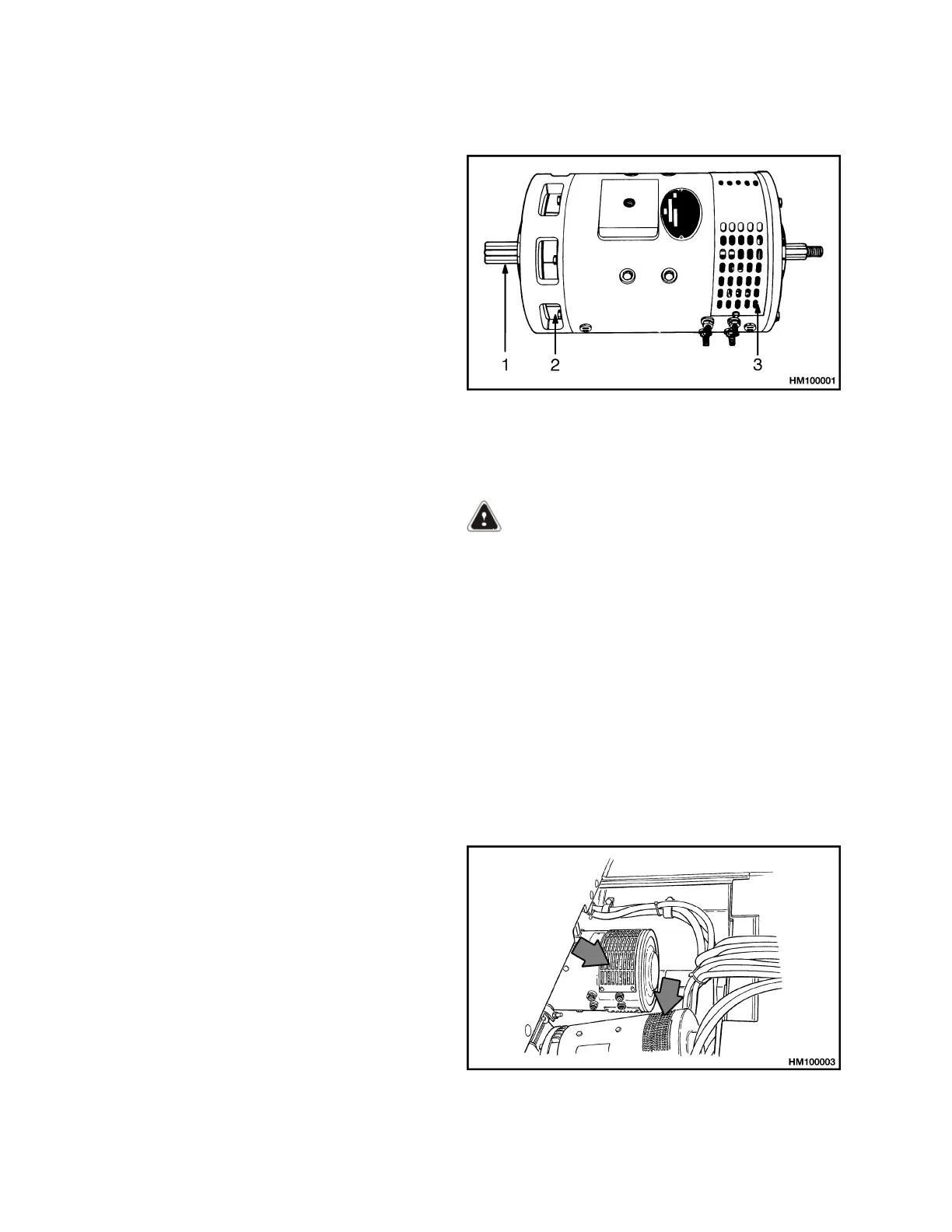

1. ARMATURE

(DRIVE) SHAFT

2. COOLING FAN

3. BRUSH COVER

Figure 1. Traction Motor

WARNING

Compressed air can move particles so that they

cause injury to the user or to other personnel.

Make sure that the path of the compressed air is

away from all personnel. Wear protective goggles

or a face shield to prevent injury to the eyes.

NOTE: Vacuum cleaning, when possible, is the rec-

ommendation of manufacturers of electric motors.

The use of compressed air can send dirt particles into

the bearings and other areas of the motor that can

cause possible damage.

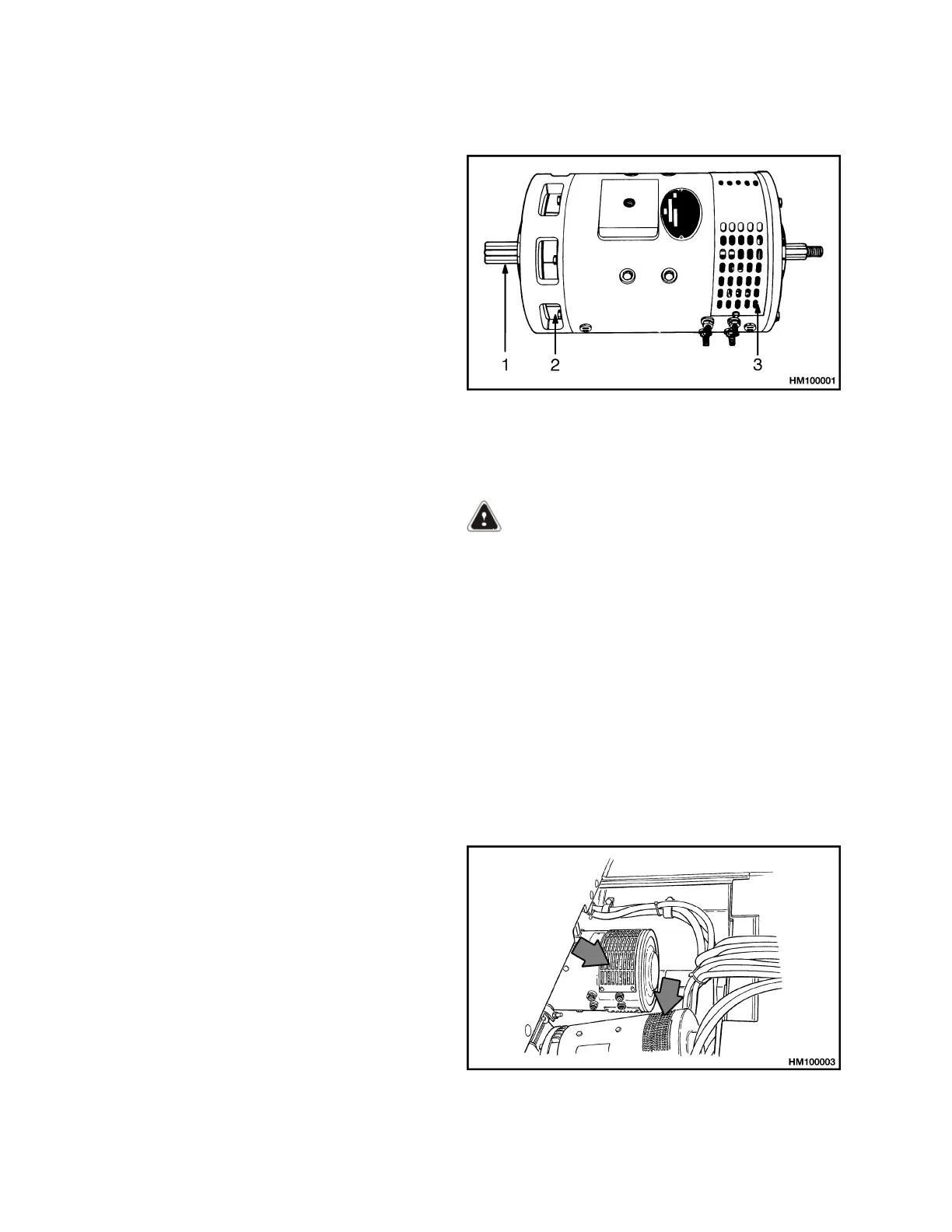

3. Remove brush covers at rear of motor. See Fig-

ure 2. Wear eye protection. Use a vacuum

cleaner or compressed air to remove dirt and

brush dust from commutator area.

Figure 2. Brush Cover Removal From Motor

Brush and Commutator Inspection 0620 YRM 0294

2

Loading...

Loading...