6. Remove drive end frame from armature.

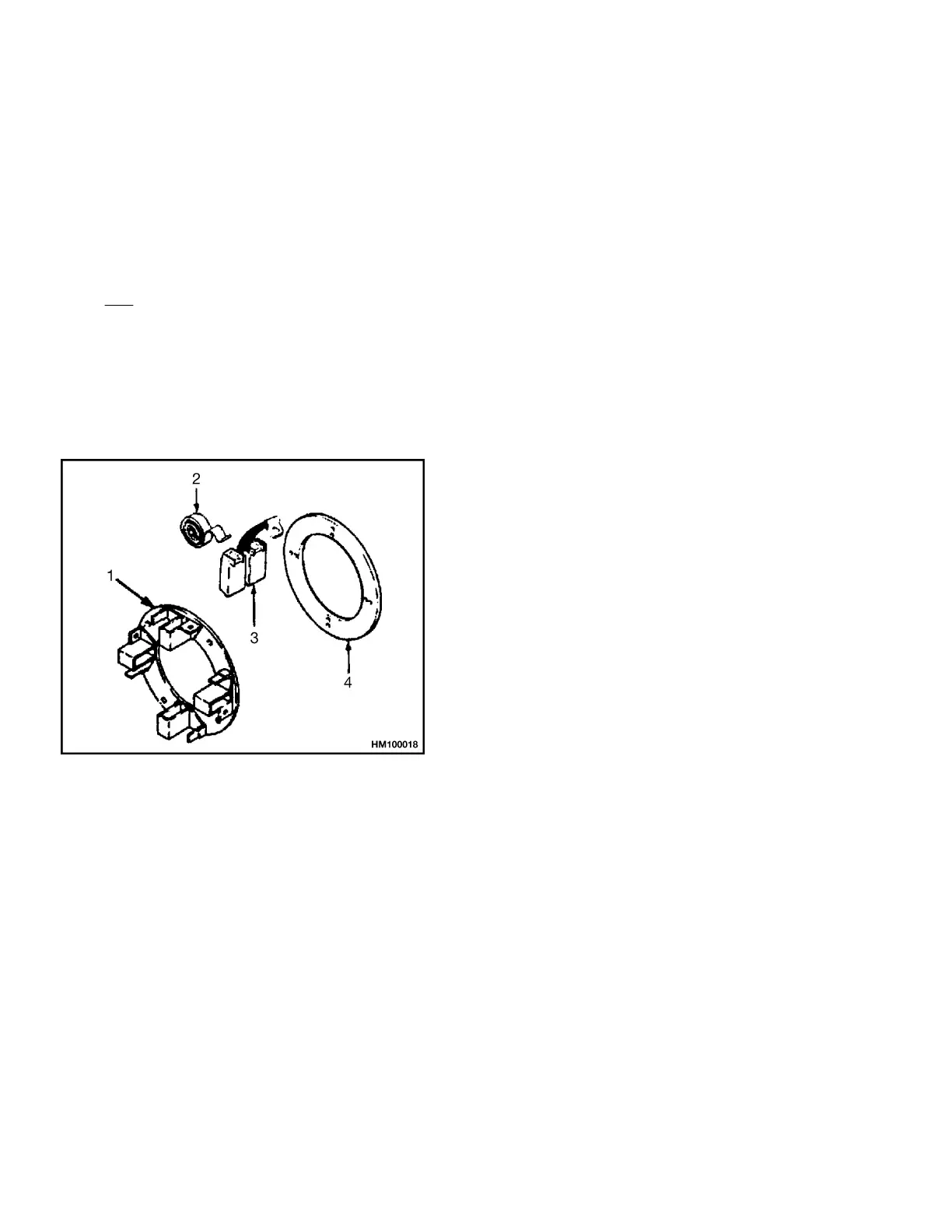

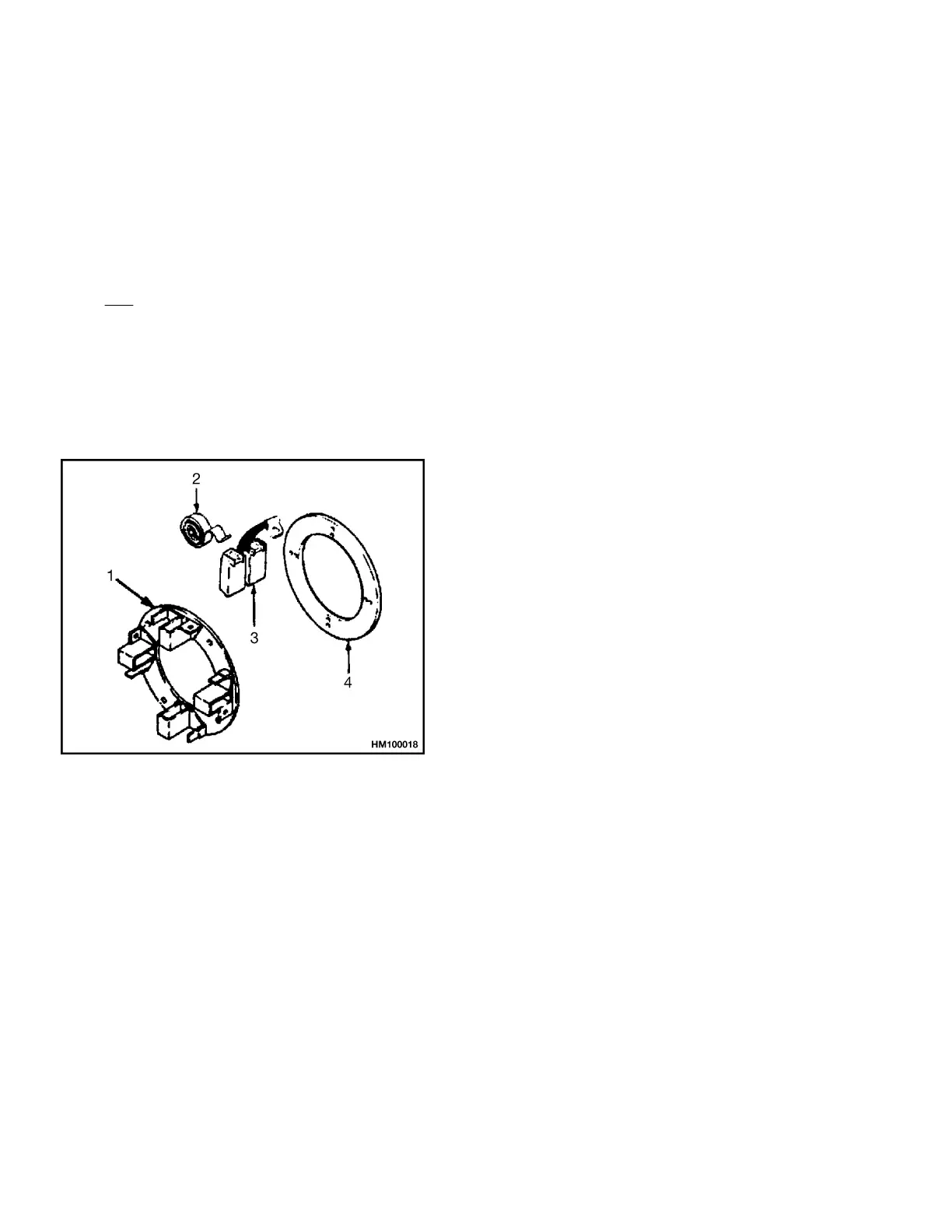

If the brush holder (1) must be loosened or re-

moved from the end frame for repairs, the brush

holder must be installed again in the same position.

See Figure 7. Make alignment marks between the

brush holder and the end frame before the brush

mounting plate (4) is released. The brush holder

must be installed again in the same position.

If a new brush holder must be installed, there will

not be an alignment mark on the new brush holder.

Make an alignment mark on end frame with a refer-

ence point on brush holder that must be removed.

Install new brush holder so reference point and

alignment mark are aligned. The new brush holder

must be installed in the same position as the old

holder so the timing will be correct.

1. BRUSH HOLDER

2. BRUSH SPRING

3. BRUSH

4. BRUSH MOUNTING PLATE

Figure 7. Brush Holder and Mounting Plate

7. Remove screws that fasten brush holder assem-

bly to commutator end frame.

8. Disassemble components of motor as necessary

to make repairs.

Steering Pump Motor

NOTE: Some lift trucks could be equipped with a

Brushless DC Power Steering motor, which is non-re-

pairable.

NOTE: Some electrical trucks use a steering pump

motor. Refer to the service manual for your truck

model for instructions on the removal and installation

of steering pump motors.

1. See Power Steering Motor and Pump for the re-

moval and installation procedures for the steering

pump motor. Make index marks on the steering

pump and the drive end frame of the motor. Re-

move two capscrews that hold steering pump to

motor. Remove pump and allow oil to drain from

drive end frame.

2. Remove brush covers. See Figure 2. Remove two

screws that hold brushes and terminal wires to

brush holders. Pull brush springs out of the way

and pull two brushes from holders.

Motors Repair 0620 YRM 0294

16

Loading...

Loading...