Operation 1900 YRM 1018

2. When making repairs, use the least number of fit-

tings and connections to minimize flow resistance

and the possibility of leakage.

HYDRAULIC OIL

The hydraulic oil in the system performs the dual func-

tion of the power transmission and lubrication. Using

the correct fluid is essential to proper system operation.

Refer to the Lubrication Charts for the recommended

hydraulic oil to be used.

Check the reservoir level when troubleshooting lifting

problems. Low oil levels will make it appear that a prob-

lem exists with the battery or hydraulic system.

CLEANLINESS

Adhere to the following precautionary steps to ensure

that the hydraulic system remains clean.

1. Flush the entire system when a failure is encoun-

tered to make sure all paint, metal chips, welding

shot, and debris are removed.

2. Filter each change of oil to prevent the introduction

of contaminants into the system.

3. Provide continuous protection from airborne con-

tamination by keeping the breather clean and ser-

viceable.

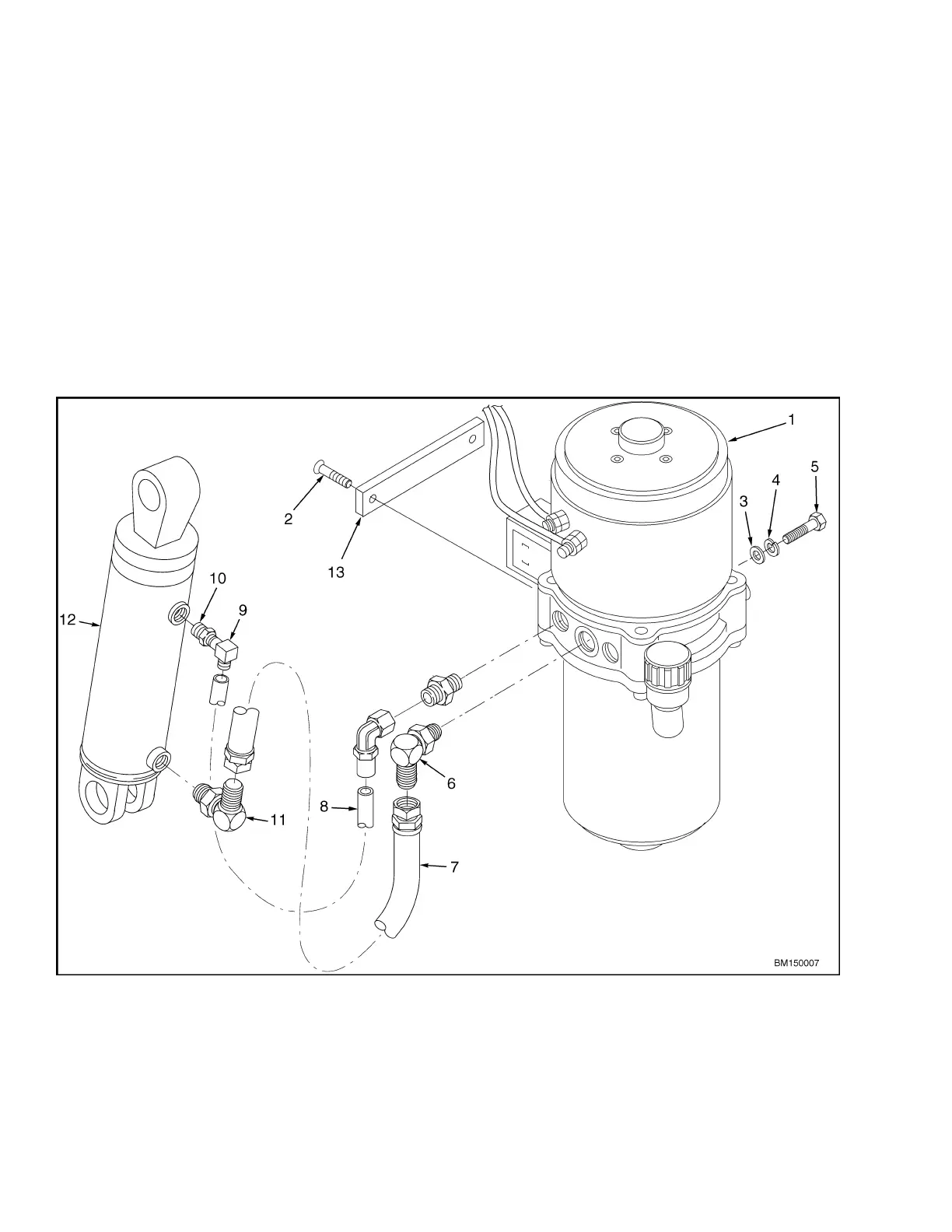

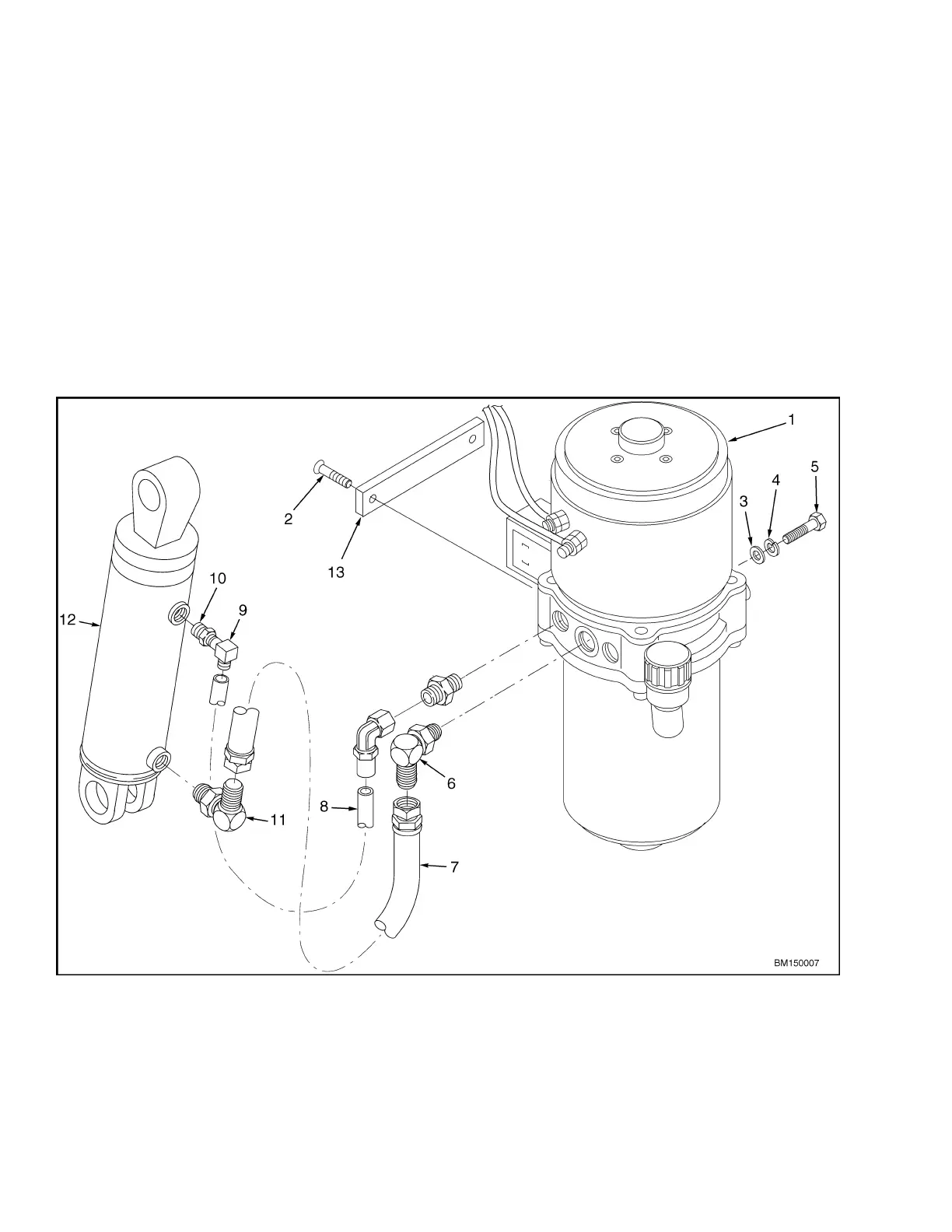

1. HYDRAULIC POWER UNIT

2. CAPSCREW

3. WASHER

4. LOCKWASHER

5. CAPSCREW

6. FITTING

7. HOSE

8. TUBE

9. FITTING

10. ADAPTER

11. FITTING

12. LIFT CYLINDER

13. SPACER PLATE

Figure 2. Hydraulic System - 12 Volt

2

Loading...

Loading...