1900 YRM 1018 Operation

General

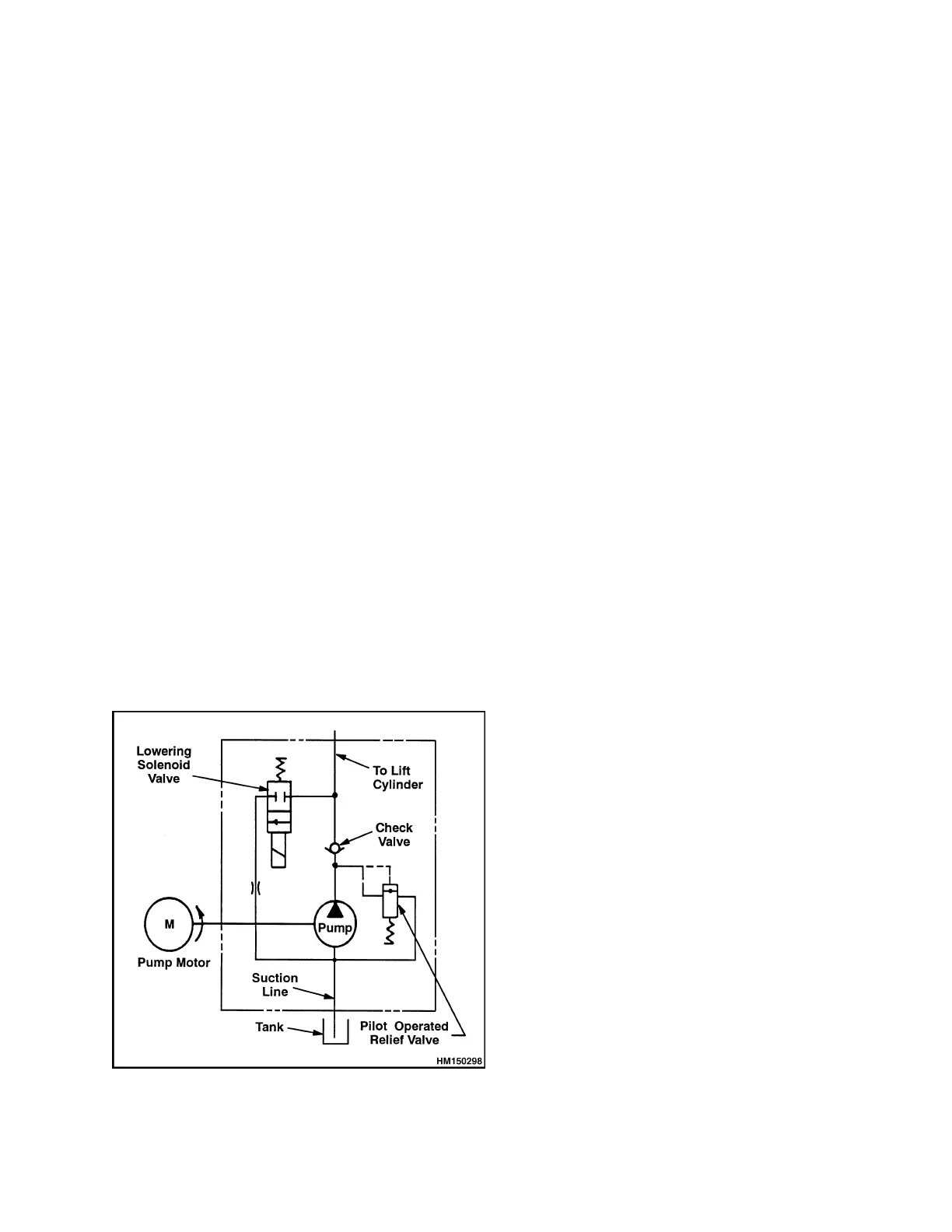

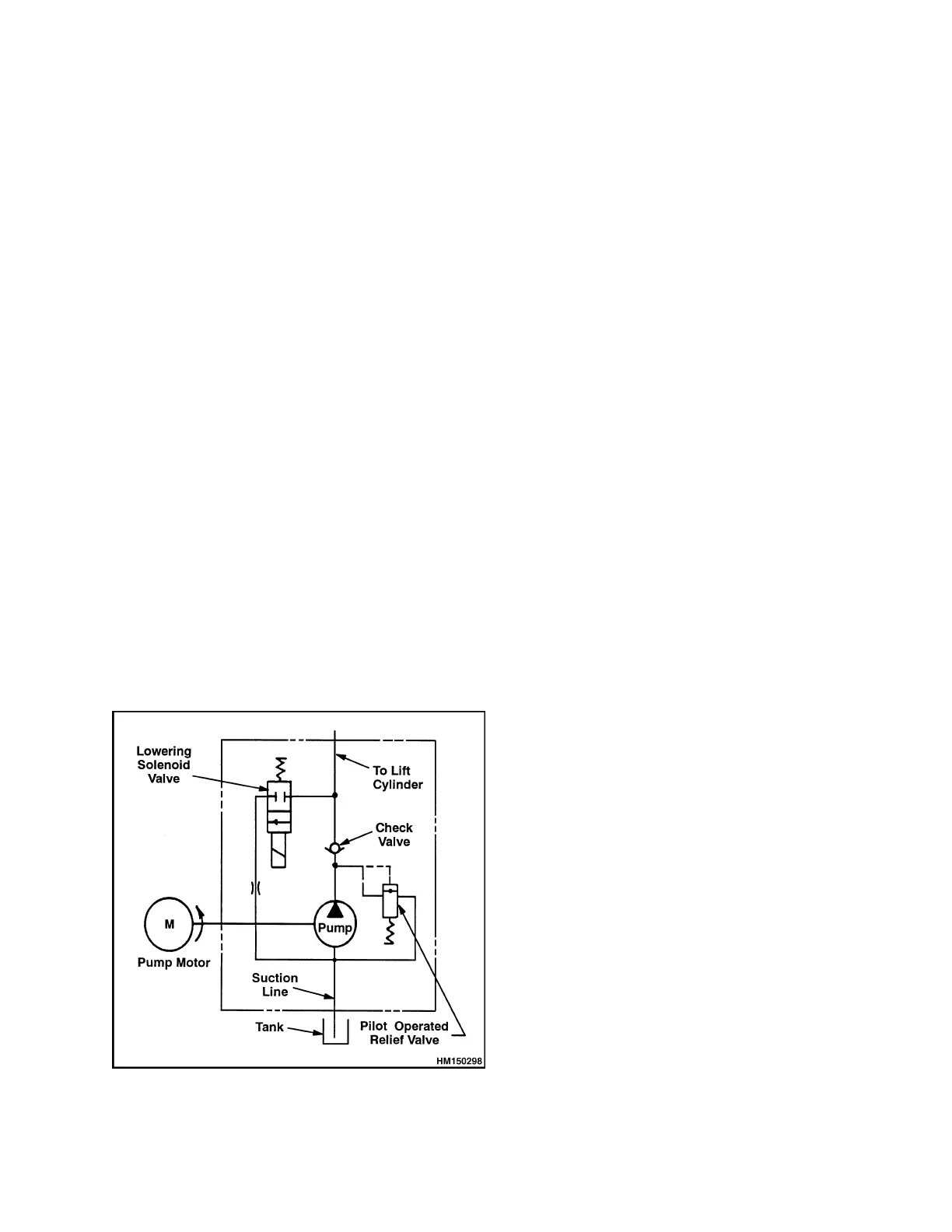

The hydraulic system provides the force required to lift

the loads on all motorized lift trucks.

The hydraulic system on the motorized lift truck consists

of the following individual components:

• Pump Motor Assembly

• Hydraulic Pump Assembly

• Solenoid Lowering Valve

• Pilot Relief Valve

• Lift Cylinder

• Reservoir

The hydraulic pump and motor assemblies are mechan-

ically joined together as a compact unit, combining the

reservoir, pump, and motor together as a single assem-

bly. The pump is located inside of the hydraulic tank and

coupled to the motor by an adapter plate, coupler drive,

and four capscrews.

Hydraulic unit servicing is best performed by removing

the unit from the truck to a clean work area.

Operation

LIFTING A LOAD

To raise a load, the lift button must be depressed. De-

pressing this switch will activate the pump motor. This

torque is transferred to the pump from the motor through

the motor shaft and shaft coupling.

Hydraulic oil is pumped through the system as the

pump begins to operate. A vacuum created inside of

the pump draws oil out of the reservoir through the suc-

tion line. Air which is drawn into the reservoir through

the breather displaces the pumped oil, allowing it to

be sent through the system. See Figure 1, Figure 2,

and Figure 3. If the breather is clogged or blocked the

ability of the system to lift a load will be greatly reduced.

Figure 1. Hydraulic Schematic

As oil is pushed out of the pump, it passes through a

one-way check valve to the lift cylinder. The check valve

prevents oil from flowing back to the pump when lifting

ceases, holding the lift cylinder in the raised position

until lowered.

The piston will begin to lift the load when fluid pressure

acting against it is high enough to overcome the weight

of the load at rest on the forks/platform.

When the piston is fully extended to the end of its stroke

or if the load is too heavy, pressure will continue to

build until the rated pressure needed to operate the

relief valve is reached. When this occurs, the relief

valve, which is normally closed, is forced back against

its spring, creating a path for the fluid to flow back to the

reservoir.

Once relief valve pressure is reached, hydraulic oil will

continue to be diverted from the lift cylinder to the reser-

voir until the lift button is released or electrical power is

interrupted.

LOWERING A LOAD

A load is lowered by depressing the lower button. When

the lower button is depressed, electric current is sent

to the normally closed solenoid lowering valve, which

causes it to change position and open a path for the

trapped hydraulic oil to flow from the cylinder back to

the reservoir.

HYDRAULIC LINES

1. All hydraulic lines must be thoroughly cleaned be-

fore installation.

1

Loading...

Loading...