xviii

Outboard Rigging Guide - 2001 General Rigging Information

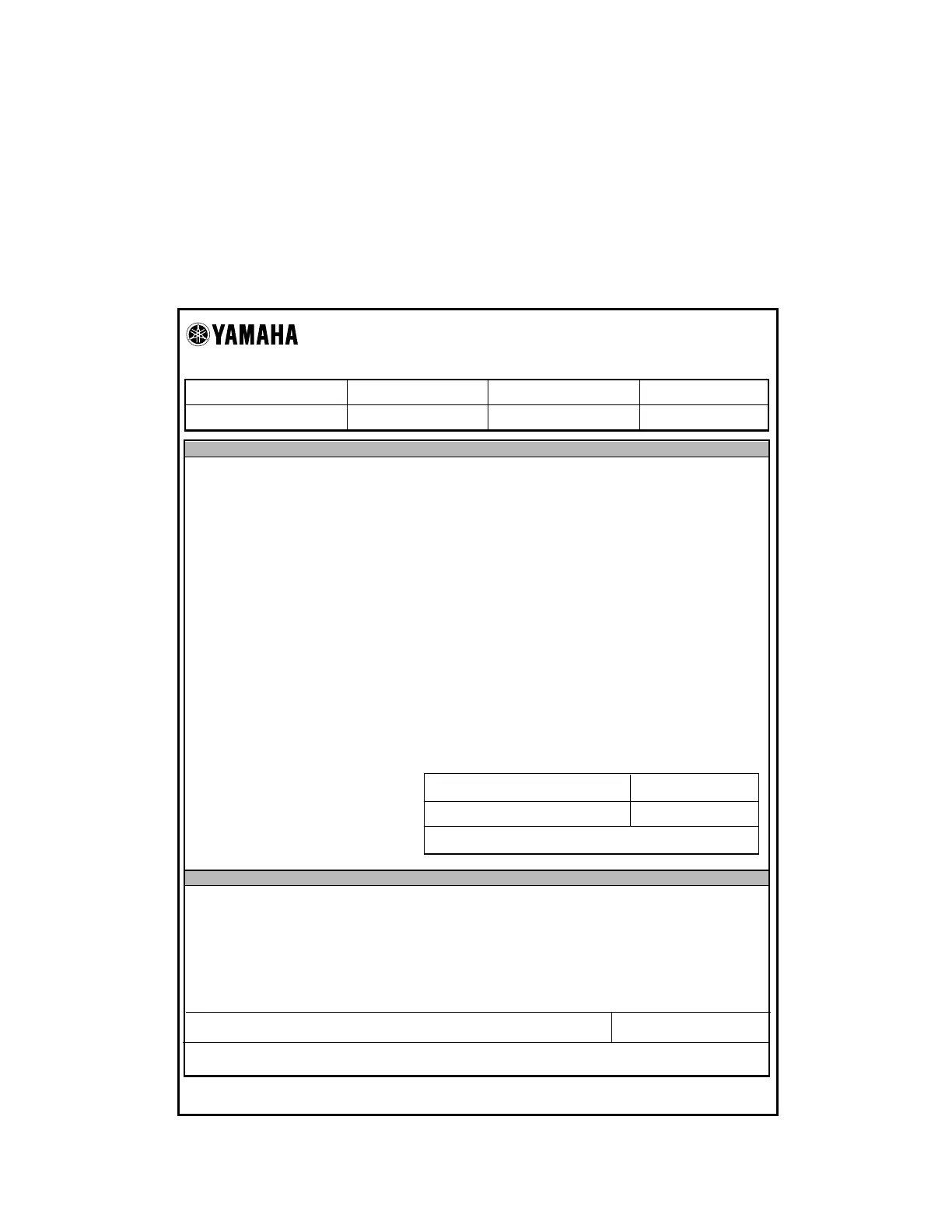

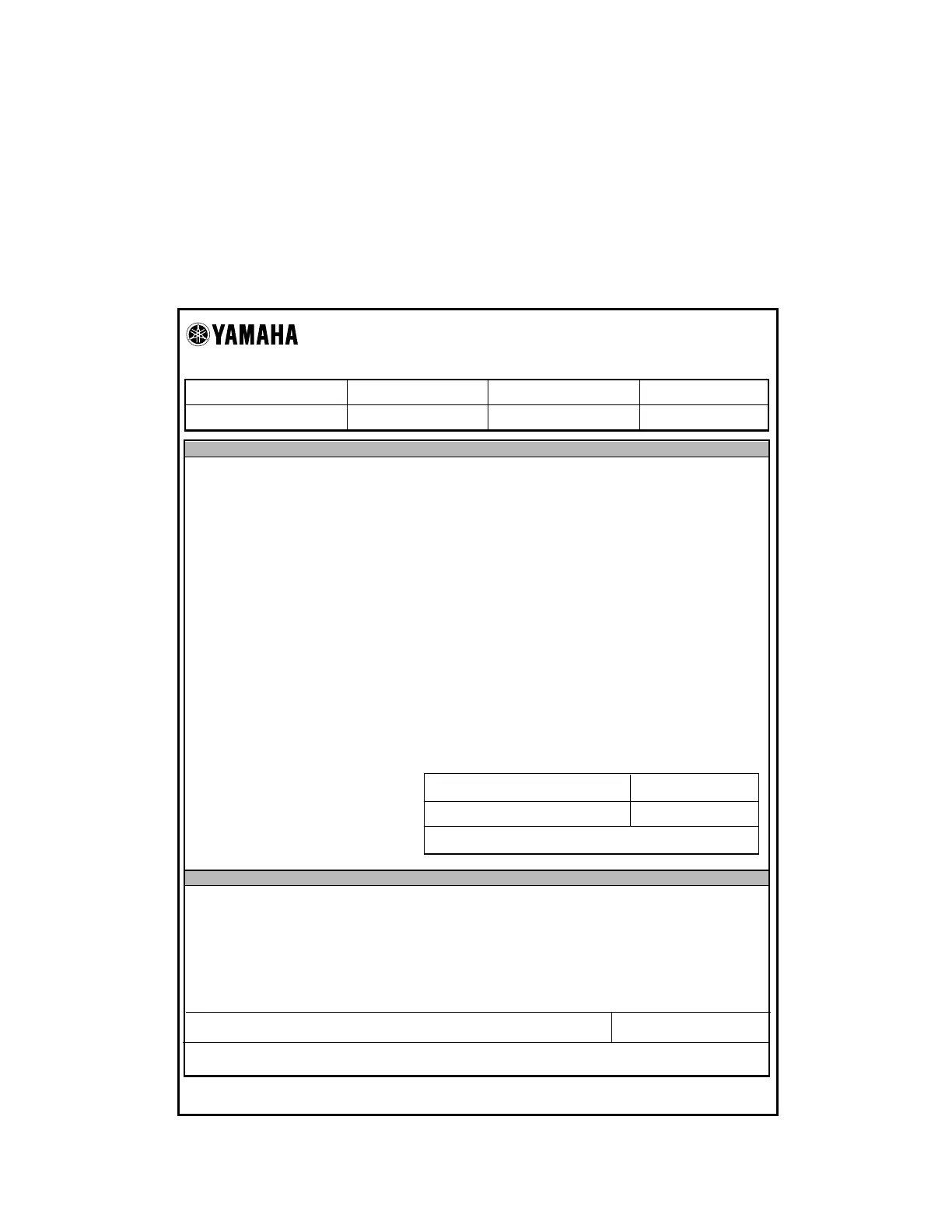

Predelivery Checklist

Before operation, go over the PDI Checklist - LIT-18161-01-2K (see illustration below). Fill in the infor-

mation required. Start the engine and perform operating checks.

NOTE: There is nothing more frustrating to a customer than to have problems with a new boat and

engine. If the customer experiences problems on delivery, they feel they have received an inferior

product. Also, the customer’s confidence level in Yamaha is greatly diminished.

OUTBOARDSmmmmmmmmmm

PREDELIVERY CHECKLISTmmmmmmmmmm

mmm

2 and 4-Stroke Models

MODEL PRIMARY ID (Single/Port) PRIMARY ID (Starboard) HULL ID NUMBER (HIN)

PROPELLER TYPE/PITCH BOAT MAKER/MODEL IGNITION KEY NUMBER TRAILER NUMBER

(P) ______________ (S) _____________ (P) __________ (S) ___________

00-067 Rev. 5/00 WHITE COPY - Dealer YELLOW COPY - Customer LIT-18161-01-2K

PREDELIVERY SERVICE

CHECK BEFORE OPERATION CHECK DURING OPERATION

RIGGING INSPECTION

❏ Engine Mounting (height, proper hardware, secured) ❏ Mark Engine Oil Tank Level

❏ Harness and Hoses are Secured and Properly Dressed ❏ No Air in Oil Injection Lines

❏ Instrument Operation/Connections Tight/Lighting ❏ Electric Starter Operation

❏ Mechanical Steering Operation/Installation ❏ Manual/Electric Choke Operation

❏ Hydraulic Steering Operation/Bleed ❏ Stop Switch/Emergency Switch Operation

❏ Fuel Line/Tank Installation/Connections Sealed/Secured ❏ Throttle Operation/Friction Adjustment Neutral/Cruising

❏ Battery Charged/Secured/Connections Tight ❏ Shifting

ENGINE SETUPAND INSPECTION

❏ Cooling System Water Flow

❏ Tiller Handle Installation/Secure ❏ Fuel/Oil/Water/Exhaust Leaks

❏ Remote Control Operation/Adjustments ❏ Power Trim/Tilt Operation

❏ Manual Tilt Operation ❏ Instrument Operation

❏ Power Trim/Tilt Fluid Level ❏ Trim Tab Adjustment (retorque after operation)

❏ Power Trim/Tilt Operation (control/pan switch) ❏ Idle RPM (Single/P) _____ (S) _____

❏ Gear Oil Level ❏ In Gear Idle RPM (Single/P)_______ (S) ______

❏ Overheat Warning System (ground sensor lead) ❏ Factory-recommended W.O.T. RPM Range ___________

❏ Visual Inspection of Engine ❏ W.O.T. RPM (Single/P)_______ (S)_______

2-Stroke Fuel and Oil Setup

❏ All Rigging Harnesses Properly Routed and Secured

❏ Premix Fuel for Break-in (except HPDI models)

❏ Bleed Oil Injection Pump

❏ Oil Pump Linkage Adjustment

❏ Oil Transfer (P) _____ (S) ______

❏ Return-to-port Switch Operation

❏ Oil Warning System Check

❏ VST Operation Fuel Pressure (fill with fuel first)

❏ HPDI High Pressure Pump Oil Level

4-Stroke Oil Setup

❏ Engine Oil Level

❏ Low Oil Pressure Warning System

(ground sensor lead)

Carburetion (2 and 4-Stroke Models)

❏ Carburetor Synchronization

❏ Throttle Plate Synchronization

❏ Manual/Electric Choke Operation

CUSTOMER DELIVERY CHECKLIST

❏

The Above Checklist Completed and Explained by Dealership ❏ 4-Stroke Use of Yamalube 4-M or Equivalent Rated Oil

❏ Operation of Equipment/Boat Accessories Explained and Ring Free Emphasized

❏ Operation/Orientation Ride with Dealership Personnel ❏ Engine Break-in Procedure Explained

❏ Owner’s Manual(s) and Keys Received ❏ Maintenance/Care Schedule Explained

❏ Customer Introduced to Service Manager/Writer ❏ Advised of First Scheduled Maintenance

❏ Return-to-Port Operations (Oil System, RPM Reduction) ❏ Warranty Coverage Explained to Customer’s Satisfaction,

❏ Gauge Operation/Warning Symbols Explained Including Customer Responsibilities Under

❏ 2-Stroke: Use of Yamalube 2-M/TC-W3

®

Oil and Ring Free ❏ Yamaha Extended Service (Y.E.S.) benefits explained

❏ Emphasized ❏ Customer Questions Answered by Dealership Personnel

CUSTOMER SIGNATURE DATE

CUSTOMER NAME

INSPECTOR’S SIGNATURE DATE

DEALER NAME PHONE NUMBER

DEALERSHIP ADDRESS

Loading...

Loading...