Yamatake Corporation Operation of the Transmitter

ST3000 Smart Transmitter Series 900 Electronic Differential Pressure/Pressure Transmitter 5-9

5-3 : Measurement with STD type

5-3-1 :Flow Rate Measurement

5-3-1-1 Preparation for Measurement

WARNING

• Make sure that the process is in the manual control mode.

If in automatic control mode, switch to manual control before starting the follow-

ing procedures.

• Drain poisonous fluids with care, making provisions to protect personnel.

• Always close the differential pressure output valve (main valve), the

drain valve, the gas vent plug (refer to figures 4-8 and 4-9) and the high

pressure side and low pressure side stop valves of the 3-way manifold

valve. Also, open the equalizer valve of the 3-way manifold valve.

Procedure 1

Lead process pressure into the pressure receiving part of the transmitter, using this

procedure:

Step Description

1 Gradually open the main valves of both the high-pressure side and the

low-pressure side (Refer to Figure 4-8 and Figure 4-9). Lead process fluid

into the connecting pipe.1

2 Fill with process fluid, the pressure-receiving part of the transmitter.

1. Gradually open the high pressure side stop valve. Close, after the pres-

sure receiving part has completely filled with process fluid.

2. Gradually open the low pressure side stop valve. Close, after the pres-

sure receiving part has completely filled with process fluid.

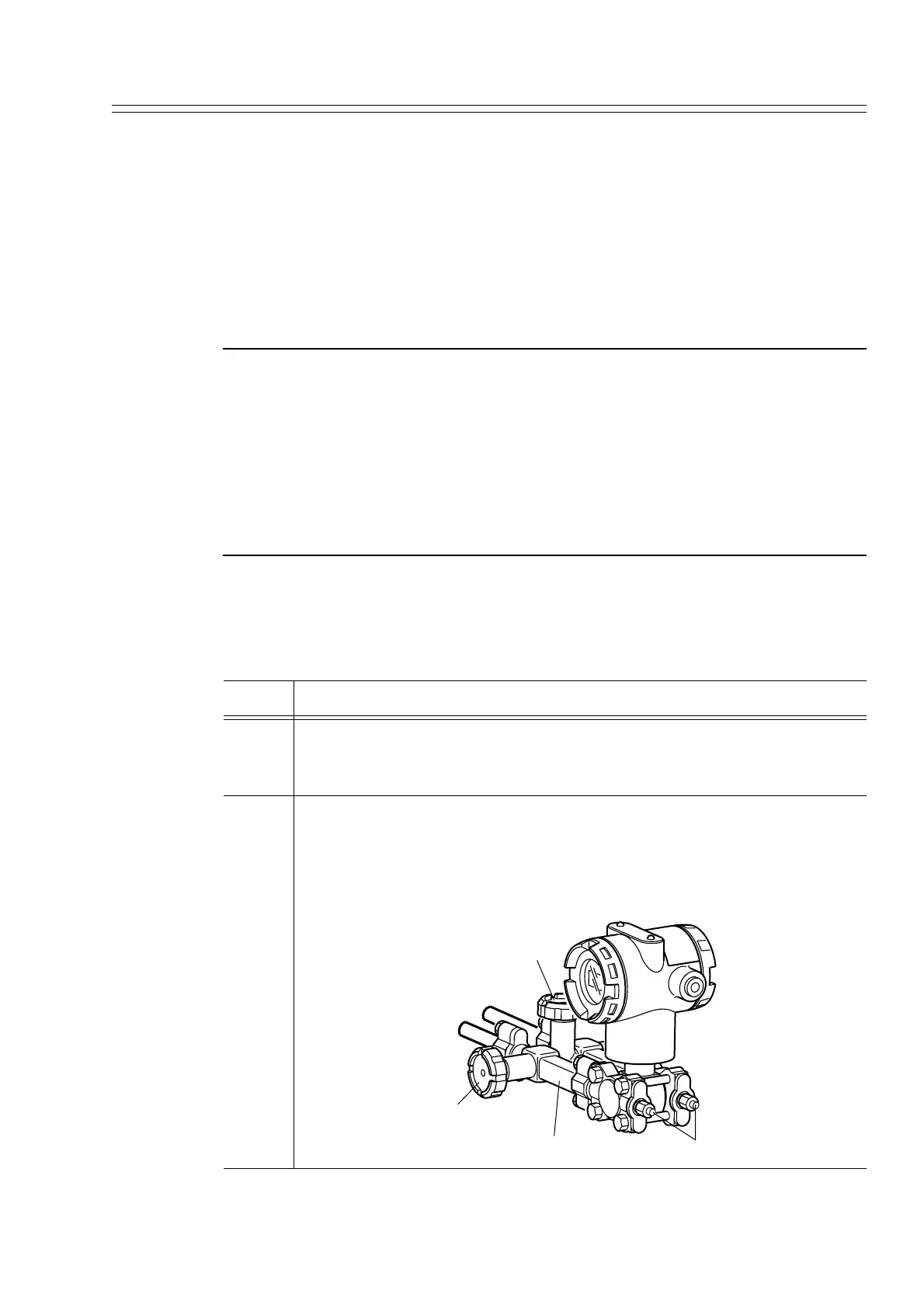

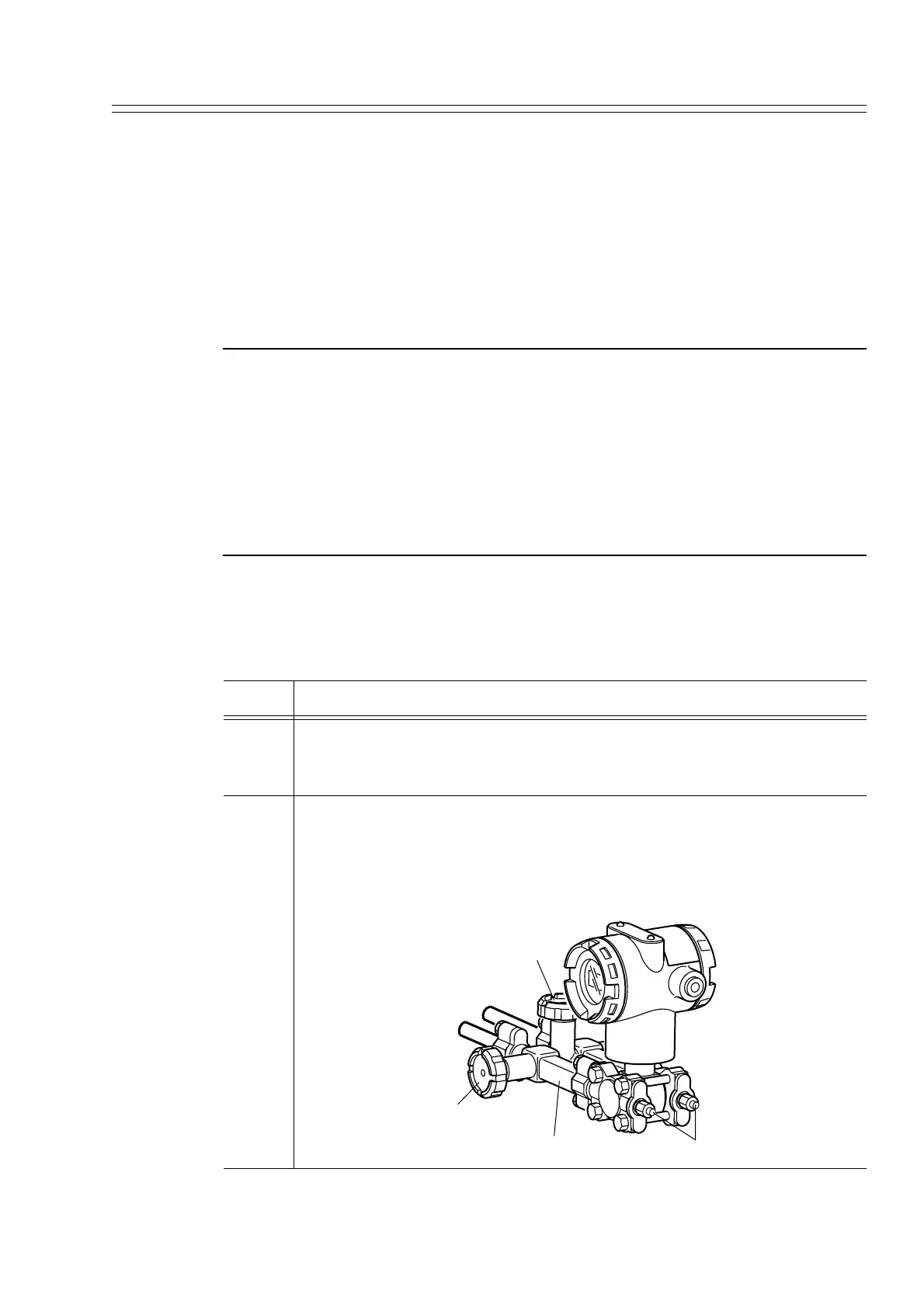

(Equalizer valve)

High-pressure side

Low-pressure side

Low-pressure side

stop valve

3-way manifold valve

Vent / Drain plug

( )

Loading...

Loading...