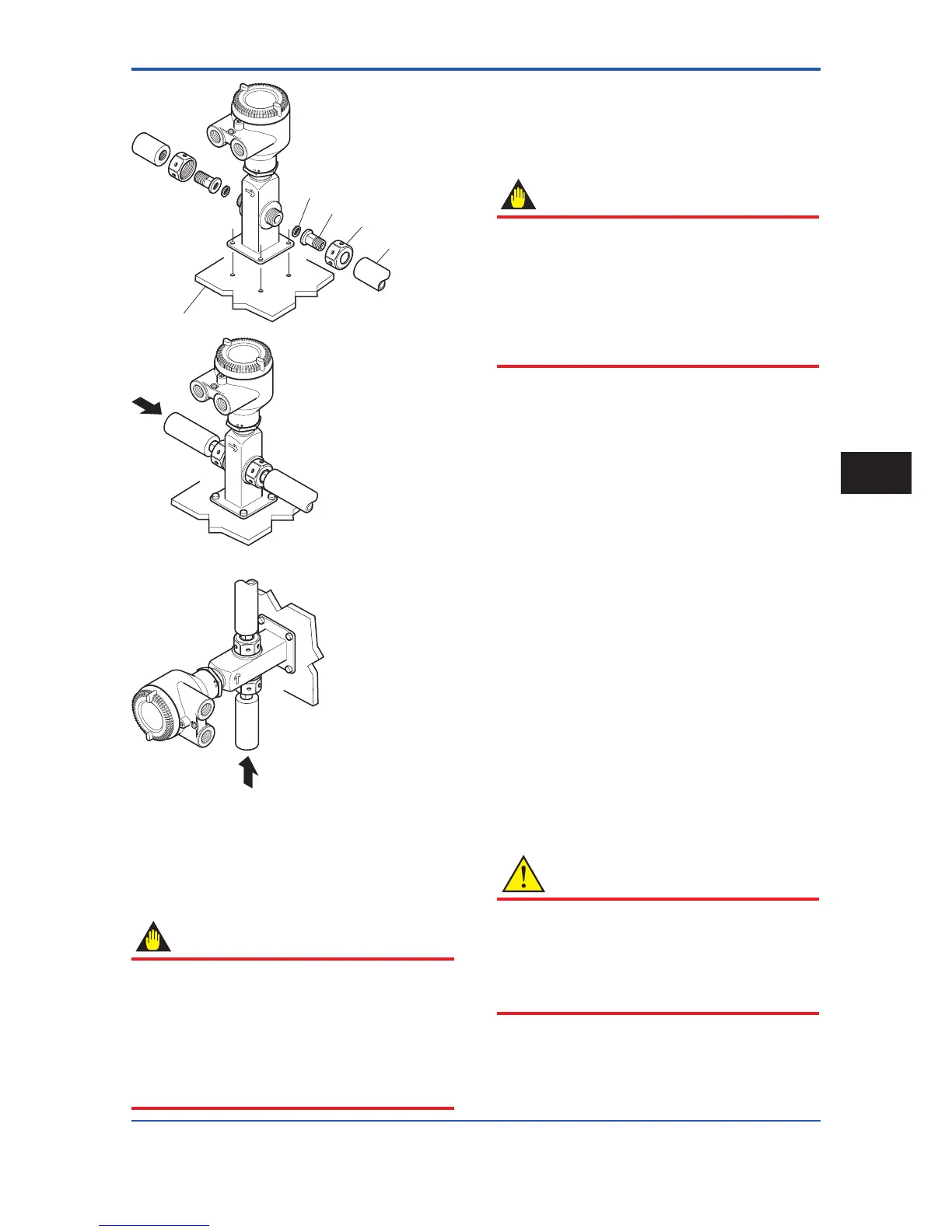

Figure 3.3.1 Mounting Procedure for Union Joint Type

(sizes: 2.5 to 10 mm (0.1 to 0.4 in.))

3.3.2 Nominal Diameter 2.5 mm (0.1 in.) to

40 mm (1.5 in.), Wafer Type

IMPORTANT

Useboltsandnutsincompliancewiththeange

ratings. When stud-type through-bolts are used, be

sure the outside diameter of the shank is smaller than

that of the thread ridge. Be sure to choose a gasket

with inner and outer diameters that does not protrude

inside the piping (refer to Table 3.3.16). If the inner

diameter of the gasket is too large, or outer diameter

ofthegasketistoosmall,uidleakagemayresult.

(1) Mounting Direction

Mounttheowmetersothattheowdirectionoftheuid

to be measured is in line with the direction of the arrow

markontheowmeter.

IMPORTANT

If it is impossible to match the direction of the arrow

mark, the direction of the electrical connection can

be changed. Refer to the applicable user’s manuals

which can be downloaded from our website.

Incasetheuidbeingmeasuredowsagainstthe

arrowdirection,changethevaluefrom“Forward”to

“Reverse”attheparameter[J20:FlowDirection]

(refer to Chapter 8).

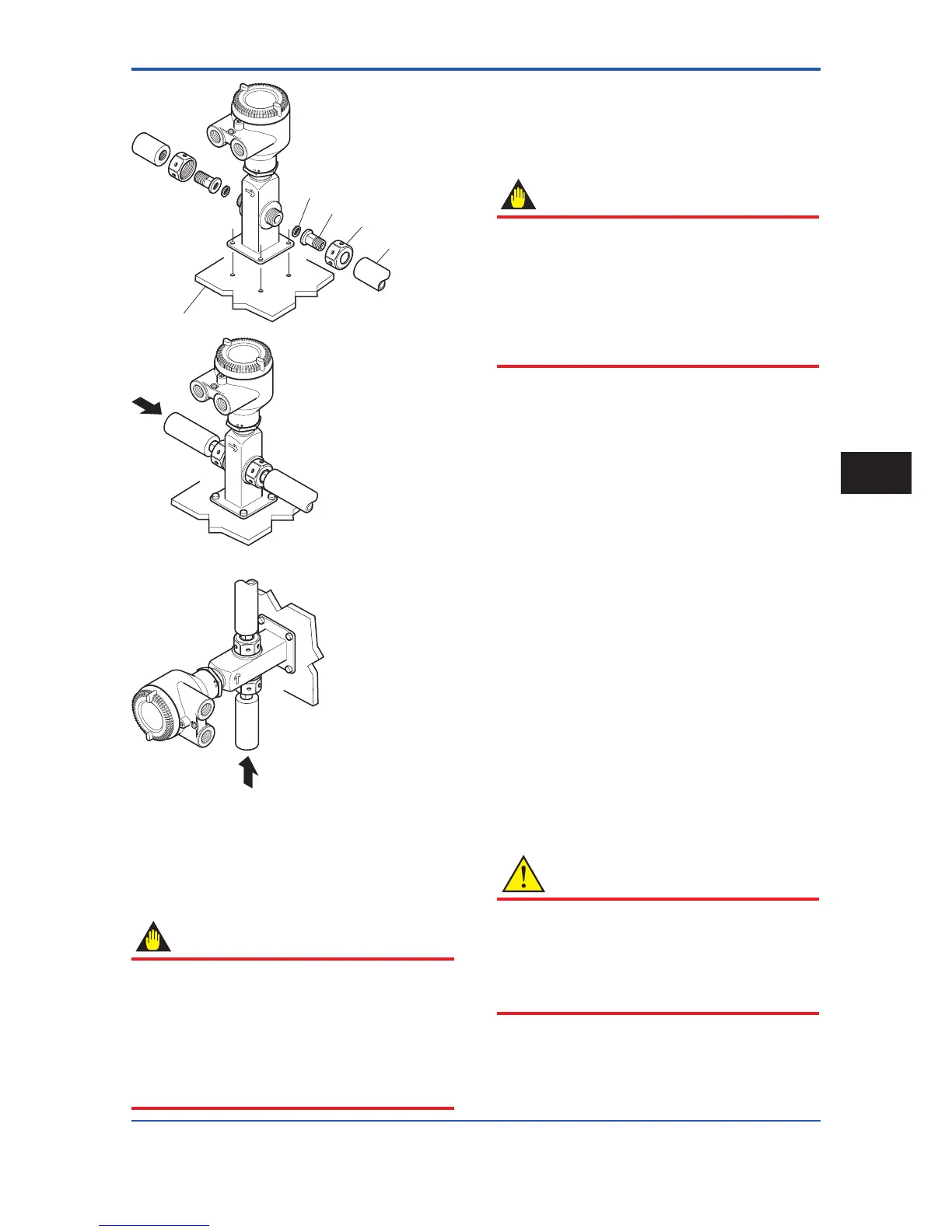

(2) Mounting Centering Devices

Tomaintainconcentricityoftheowmeterwiththe

pipes,installcenteringdevicesontheMini-angesof

theowmeter.Usetheappropriatecenteringdevices

accordingtothenominaldiameterandtheangeratings.

(3) Positioning the Flowmeter

Pass two through-bolts through the adjacent holes of

bothangesandpositiontheowmetersothattheMini-

angesandthecenteringdevicescomeinclosecontact

with each other. Pass the other through-bolts through

the other holes (refer to Figure 3.3.2 and Figure 3.3.3).

In case stud-type through-bolts are used, position them

in such a way that the centering devices come in contact

with the bolt threads.

(4) Tightening Nuts

Tighten the nuts according to the torque values for metal

piping in Table 3.3.4. For PVC piping, select an optional

code of GA, GC, or GD, use rubber gaskets and tighten

the nuts to the torque values for PVC piping in Table

3.3.5.

Forpermeableuids(suchasnitricacid,hydrouoric

acid, or sodium hydrate at high temperatures), tighten the

nuts according to the torque values in Table 3.3.6.

CAUTION

ForaowmeterwithuorocarbonPFAlining,itis

possible that the nuts may loosen as time passes,

so tighten them regularly. Be sure to tighten the nuts

according to the prescribed torque values. Tighten

them diagonally with the same torque values, step by

step up to the prescribed torque value.

Loading...

Loading...