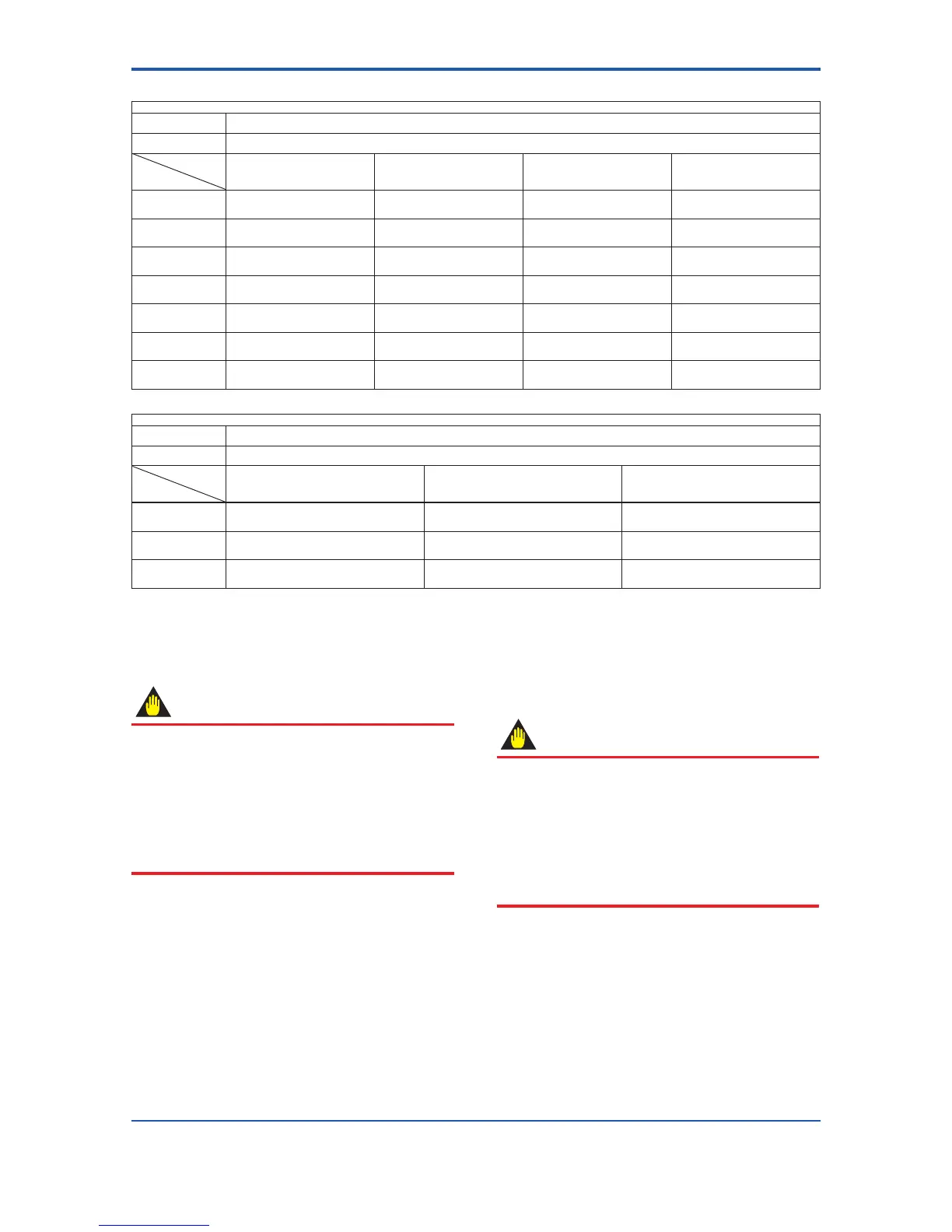

Table 3.3.6 Wafer Type Tightening Torque Values for Metal Piping and Permeable Fluids

Tightening torque values for PFA lining type (N-m / {kgf-cm} / [in-lbf])

Gasket types within

owtube

No gasket (standard)

Gasket types for user’s

ange

PTFE-sheathed non-asbestos gasket (optional codes BCF and BSF), or the equivalent in hardness

Flange

ratings

Size

mm (inch)

JIS 10K

ANSI Class 150

DIN PN10

JIS 20K

ANSI Class 300

DIN PN16

DIN PN40 JPI Class 150

2.5 (0.1)

10.8 to 12.4

{110.1 to 126.4}

[95.59 to 109.7]

10.8 to 12.4

{110.1 to 126.4}

[95.59 to 109.7]

11.1 to 12.4

{113.2 to 126.4}

[98.24 to 109.7]

11.8 to 12.1

{120.6 to 123.7}

[104.6 to 107.3]

5 (0.2)

10.8 to 12.4

{110.1 to 126.4}

[95.59 to 109.7]

10.8 to 12.4

{110.1 to 126.4}

[95.59 to 109.7]

11.1 to 12.4

{113.2 to 126.4}

[98.24 to 109.7]

11.8 to 12.1

{120.6 to 123.7}

[104.6 to 107.3]

10 (0.4)

10.8 to 12.4

{110.1 to 126.4}

[95.59 to 109.7]

10.8 to 12.4

{110.1 to 126.4}

[95.59 to 109.7]

11.1 to 12.4

{113.2 to 126.4}

[98.24 to 109.7]

11.8 to 12.1

{120.6 to 123.7}

[104.6 to 107.3]

15 (0.5)

10.8 to 12.4

{110.1 to 126.4}

[95.59 to 109.7]

10.8 to 12.4

{110.1 to 126.4}

[95.59 to 109.7]

11.1 to 12.4

{113.2 to 126.4}

[98.24 to 109.7]

11.8 to 12.1

{120.6 to 123.7}

[104.6 to 107.3]

25 (1.0)

34.9 to 40.1

{355.9 to 408.9}

[308.9 to 354.9]

35.2 to 40.1

{358.9 to 408.9}

[311.5 to 354.9]

32.3 to 37.1

{329.4 to 378.3}

[285.9 to 328.4]

29.2 to 29.9

{297.6 to 305.5}

[258.1 to 265.0]

32 (1.25)

38.8 to 44.6

{395.6 to 454.8}

[343.4 to 394.7]

39.2 to 44.6

{399.7 to 454.8}

[346.9 to 394.7]

40.6 to 46.7

{414.0 to 476.2}

[359.3 to 413.3]

―

40 (1.5)

53.5 to 61.5

{545.5 to 627.1}

[473.5 to 544.3]

54.2 to 61.5

{552.7 to 627.1}

[479.7 to 544.3]

56.4 to 61.5

{575.1 to 627.1}

[499.2 to 544.3]

44.6 to 45.8

{455.0 to 467.3}

[394.7 to 405.3]

Tightening torque values for Ceramics lining type (N-m / {kgf-cm} / [in-lbf])

Gasket types within

owtube

Fluororesinwithceramicllers(Valqua#7020)gasket(standard),oruororesinwithcarbongasket(optionalcodeGF)

Gasket types for user’s

ange

PTFE-sheathed non-asbestos gasket (optional codes BCF and BSF), or the equivalent in hardness

Flange

ratings

Size

mm (inch)

JIS 10K

ANSI Class 150

DIN PN10

JIS 20K

ANSI Class 300

DIN PN16

DIN PN40

15 (0.5)

8.1 to 13.1

{82.6 to 133.6}

[71.7 to 115.9]

8.1 to 13.1

{82.6 to 133.6}

[71.7 to 115.9]

7.9 to 13.1

{80.6 to 133.6}

[69.9 to 115.9]

25 (1.0)

22.5 to 29.0

{229.4 to 295.7}

[199.1 to 256.7]

22.7 to 29.0

{231.5 to 295.7}

[200.9 to 256.7]

17.4 to 29.0

{177.4 to 295.7}

[154.0 to 256.7]

40 (1.5)

40.6 to 53.8

{414.0 to 548.6}

[359.3 to 476.2]

49.3 to 67.7

{502.7 to 690.3}

[436.3 to 599.2]

40.6 to 67.7

{414.0 to 690.3}

[359.3 to 599.2]

3.3.3 Nominal Diameter 50 mm (2.0 in.) to

300 mm (12.0 in.), Wafer Type

IMPORTANT

Useboltsandnutsincompliancewiththeange

ratings. When stud-type through-bolts are used, be

sure the outside diameter of the shank is smaller than

that of the thread ridge. Be sure to choose a gasket

with inner and outer diameters that does not protrude

inside the piping (refer to Table 3.3.16). If the inner

diameter of the gasket is too large, or outer diameter

ofthegasketistoosmall,uidleakagemayresult.

(1) Mounting Direction

Mounttheowmetersothattheowdirectionoftheuid

to be measured is in line with the direction of the arrow

markontheowmeter.

IMPORTANT

If it is impossible to match the direction of the arrow

mark, the direction of the electrical connection can

be changed. Refer to the applicable user’s manuals

which can be downloaded from our website.

Incasetheuidbeingmeasuredowsagainstthe

arrowdirection,changethevaluefrom“Forward”to

“Reverse”attheparameter[J20:FlowDirection]

(refer to Chapter 8).

Loading...

Loading...