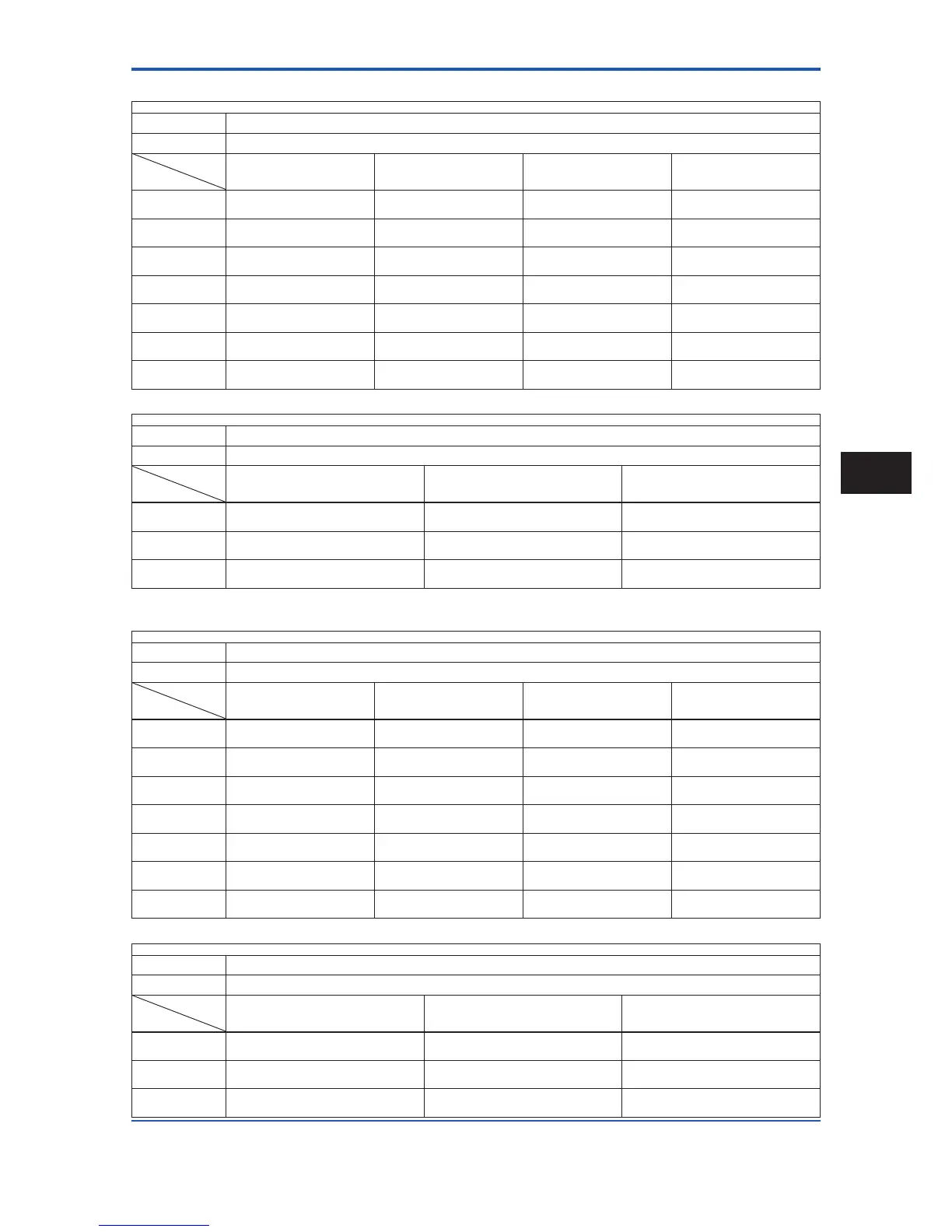

Table 3.3.4 Wafer Type Tightening Torque Values for Metal Piping

Tightening torque values for PFA/Polyurethane Rubber lining type (N-m / {kgf-cm} / [in-lbf])

Gasket types within

owtube

No gasket (standard)

Gasket types for user’s

ange

Non-asbestosbergasket,PTFE-sheathednon-asbestosgasket(optionalcodesBCFandBSF),ortheequivalentinhardness

Flange

ratings

Size

mm (inch)

JIS 10K

ANSI Class 150

DIN PN10

JIS 20K

ANSI Class 300

DIN PN16

DIN PN40 JPI Class 150

2.5 (0.1)

7.2 to 8.4

{73.42 to 85.66}

[63.72 to 74.35]

7.3 to 8.4

{74.44 to 85.66}

[64.61 to 74.35]

7.6 to 8.4

{77.5 to 85.66}

[67.26 to 74.35]

7.9 to 12.7

{80.8 to 129.9}

[70.1 to 112.7]

5 (0.2)

7.2 to 8.4

{73.42 to 85.66}

[63.72 to 74.35]

7.3 to 8.4

{74.44 to 85.66}

[64.61 to 74.35]

7.6 to 8.4

{77.5 to 85.66}

[67.26 to 74.35]

7.9 to 12.7

{80.8 to 129.9}

[70.1 to 112.7]

10 (0.4)

7.2 to 8.4

{73.42 to 85.66}

[63.72 to 74.35]

7.3 to 8.4

{74.44 to 85.66}

[64.61 to 74.35]

7.6 to 8.4

{77.5 to 85.66}

[67.26 to 74.35]

7.9 to 12.7

{80.8 to 129.9}

[70.1 to 112.7]

15 (0.5)

7.2 to 8.4

{73.42 to 85.66}

[63.72 to 74.35]

7.3 to 8.4

{74.44 to 85.66}

[64.61 to 74.35]

7.6 to 8.4

{77.5 to 85.66}

[67.26 to 74.35]

7.9 to 12.7

{80.8 to 129.9}

[70.1 to 112.7]

25 (1.0)

23.5 to 27.3

{239.6 to 278.4}

[208 to 241.6]

23.7 to 27.3

{241.7 to 278.4}

[209.8 to 241.6]

22.3 to 27.3

{227.4 to 278.4}

[197.4 to 241.6]

19.6 to 21.8

{200.0 to 222.1}

[173.5 to 192.6]

32 (1.25)

26.2 to 30.5

{267.2 to 311}

[231.9 to 269.9]

26.6 to 30.5

{271.2 to 311}

[235.4 to 269.9]

28.0 to 30.5

{285.5 to 311}

[247.8 to 269.9]

―

40 (1.5)

36.2 to 42.4

{369.1 to 432.4}

[320.4 to 375.3]

36.9 to 42.4

{376.3 to 432.4}

[326.6 to 375.3]

39.1 to 42.4

{398.7 to 432.4}

[346.1 to 375.3]

30.1 to 33.4

{307.2 to 341.3}

[266.5 to 296.0]

Tightening torque values for Ceramics lining type (N-m / {kgf-cm} / [in-lbf])

Gasket types within

owtube

Fluororesinwithceramicllers(Valqua#7020)(standard)gasket,oruororesinwithcarbongasket(optionalcodeGF)

Gasket types for user’s

ange

Non-asbestos gasket, PTFE-sheathed non-asbestos gasket (optional codes BCF and BSF), or the equivalent in hardness

Flange

ratings

Size

mm (inch)

JIS 10K

ANSI Class 150

DIN PN10

JIS 20K

ANSI Class 300

DIN PN16

DIN PN40

15 (0.5)

6.8 to 11.0

{69.3 to 112.2}

[60.2 to 97.4]

6.8 to 11.0

{69.3 to 112.2}

[60.2 to 97.4]

6.6 to 11.0

{67.3 to 112.2}

[58.4 to 97.4]

25 (1.0)

18.9 to 24.5

{192.7 to 249.8}

[167.3 to 216.8]

19.1 to 24.5

{194.8 to 249.8}

[169.0 to 216.8]

14.7 to 24.5

{149.9 to 249.8}

[130.1 to 216.8]

40 (1.5)

34.5 to 45.7

{351.8 to 466.0}

[305.4 to 404.5]

41.7 to 57.4

{425.2 to 585.3}

[369.1 to 508.0]

34.5 to 57.4

{351.8 to 585.3}

[305.4 to 508.0]

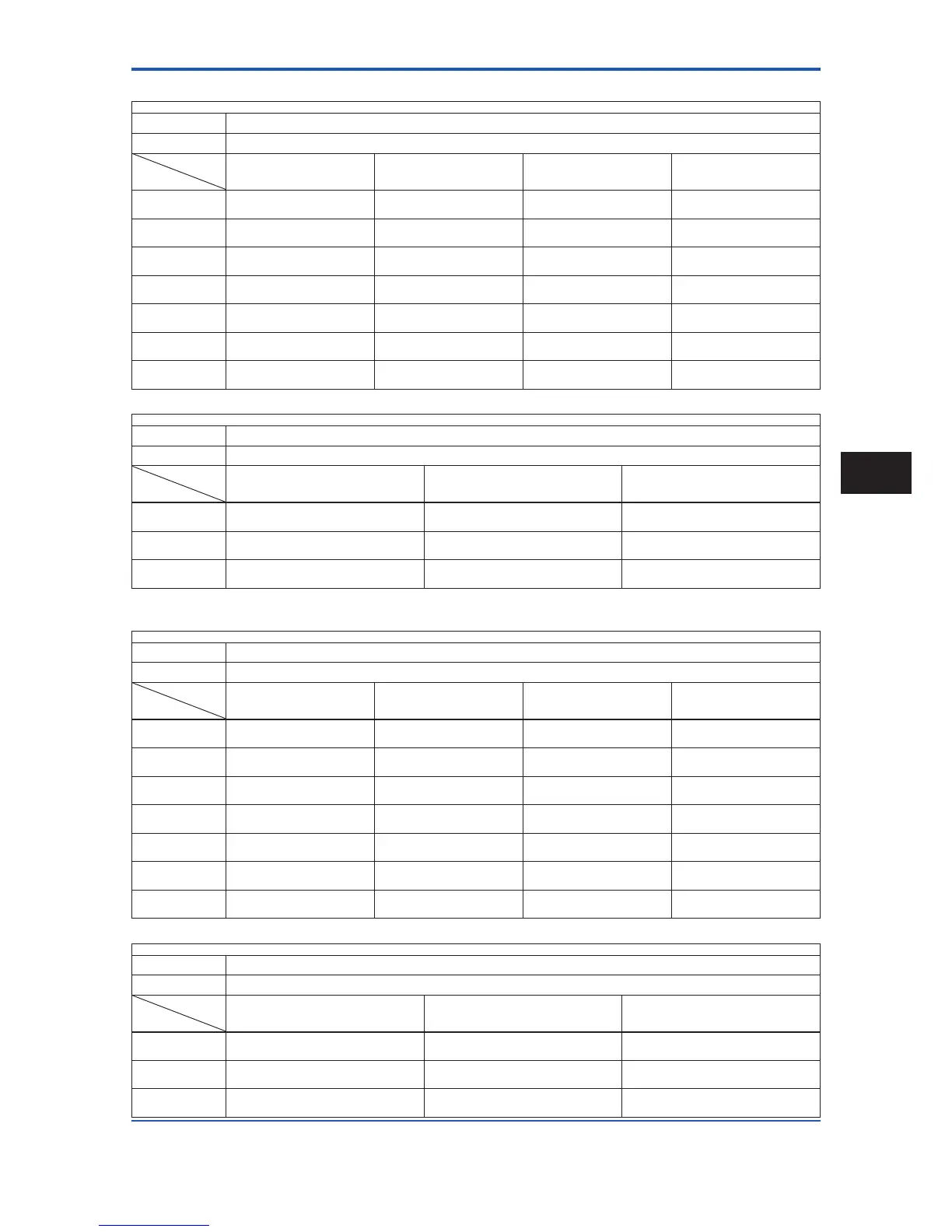

Table 3.3.5 Wafer Type Tightening Torque Values for PVC Piping

Tightening torque values for PFA lining type (N-m / {kgf-cm} / [in-lbf])

Gasket types within

owtube

Fluororubber gasket (optional codes GA, GC, and GD)

Gasket types for user’s

ange

Fluororubber gasket, chloroprene rubber gasket (optional codes BSC and BCC), or the equivalent in hardness

Flange

ratings

Size

mm (inch)

JIS 10K

ANSI Class 150

DIN PN10

JIS 20K

ANSI Class 300

DIN PN16

DIN PN40 JPI Class 150

2.5 (0.1)

1.5 to 2.5

{15.3 to 25.49}

[13.28 to 22.13]

1.5 to 2.5

{15.3 to 25.49}

[13.28 to 22.13]

1.5 to 2.4

{15.3 to 24.47}

[13.28 to 21.24]

1.6 to 2.6

{16.4 to 26.5}

[14.2 to 23.0]

5 (0.2)

1.5 to 2.5

{15.3 to 25.49}

[13.28 to 22.13]

1.5 to 2.5

{15.3 to 25.49}

[13.28 to 22.13]

1.5 to 2.4

{15.3 to 24.47}

[13.28 to 21.24]

1.6 to 2.6

{16.4 to 26.5}

[14.2 to 23.0]

10 (0.4)

1.5 to 2.5

{15.3 to 25.49}

[13.28 to 22.13]

1.5 to 2.5

{15.3 to 25.49}

[13.28 to 22.13]

1.5 to 2.4

{15.3 to 24.47}

[13.28 to 21.24]

1.6 to 2.6

{16.4 to 26.5}

[14.2 to 23.0]

15 (0.5)

1.5 to 2.5

{15.3 to 25.49}

[13.28 to 22.13]

1.5 to 2.5

{15.3 to 25.49}

[13.28 to 22.13]

1.5 to 2.4

{15.3 to 24.47}

[13.28 to 21.24]

1.6 to 2.6

{16.4 to 26.5}

[14.2 to 23.0]

25 (1.0)

4.9 to 8.1

{49.97 to 82.6}

[43.37 to 71.69]

5.0 to 8.3

{50.99 to84.64 }

[44.25 to 73.46]

4.3 to 7.2

{43.85 to 73.42}

[38.06 to 63.72]

4.0 to 6.6

{41.3 to 67.0}

[35.8 to 58.1]

32 (1.25)

5.5 to 9.2

{56.08 to 93.81}

[48.68 to 81.43]

5.7 to 9.5

{58.12 to 96.87}

[50.45 to 84.08]

5.4 to 8.9

{55.06 to 90.75}

[47.79 to 78.77]

―

40 (1.5)

7.7 to 12.9

{78.52 to 131.5}

[68.15 to 114.2]

8.1 to 13.4

{82.6 to 136.6}

[71.69 to 118.6]

7.5 to 12.5

{76.48 to 127.5}

[66.38 to 110.6]

6.4 to 10.4

{65.4 to 106.6}

[56.7 to 92.4]

Tightening torque values for Ceramics lining type (N-m / {kgf-cm} / [in-lbf])

Gasket types within

owtube

Fluororubber gasket (optional codes GA, GC, and GD)

Gasket types for user’s

ange

Fluororubber gasket, chloroprene rubber gasket (optional codes BSC and BCC), or the equivalent in hardness

Flange

ratings

Size

mm (inch)

JIS 10K

ANSI Class 150

DIN PN10

JIS 20K

ANSI Class 300

DIN PN16

DIN PN40

15 (0.5)

0.8 to 1.4

{8.2 to 14.3}

[7.1 to 12.4]

0.8 to 1.4

{8.2 to 14.3}

[7.1 to 12.4]

0.8 to 1.4

{8.2 to 14.3}

[7.1 to 12.4]

25 (1.0)

2.3 to 3.1

{23.5 to 31.6}

[20.4 to 27.4]

2.4 to 3.1

{24.5 to 31.6}

[21.2 to 27.4]

1.9 to 3.1

{19.4to 31.6}

[16.8 to 27.4]

40 (1.5)

4.4 to 6.0

{44.9 to 61.2}

[38.9 to 53.1]

5.2 to 7.3

{53.0 to 74.4}

[46.0 to 64.6]

4.4 to 7.3

{44.9 to 74.4}

[38.9 to 64.6]

Loading...

Loading...