(3) Conduit Wiring

When wiring the conduits, pass the conduit through the

wiring connection port, and utilize the waterproof gland to

preventwaterfromowingin.Placetheconduitpipeon

an angle as shown in Figure 4.1.4.

Install a drain valve at the low end of the vertical pipe, and

open the valve regularly.

Drain valve

Figure 4.1.4 Conduit Wiring

4.1.4 Wiring Connections for Integral

Flowmeter

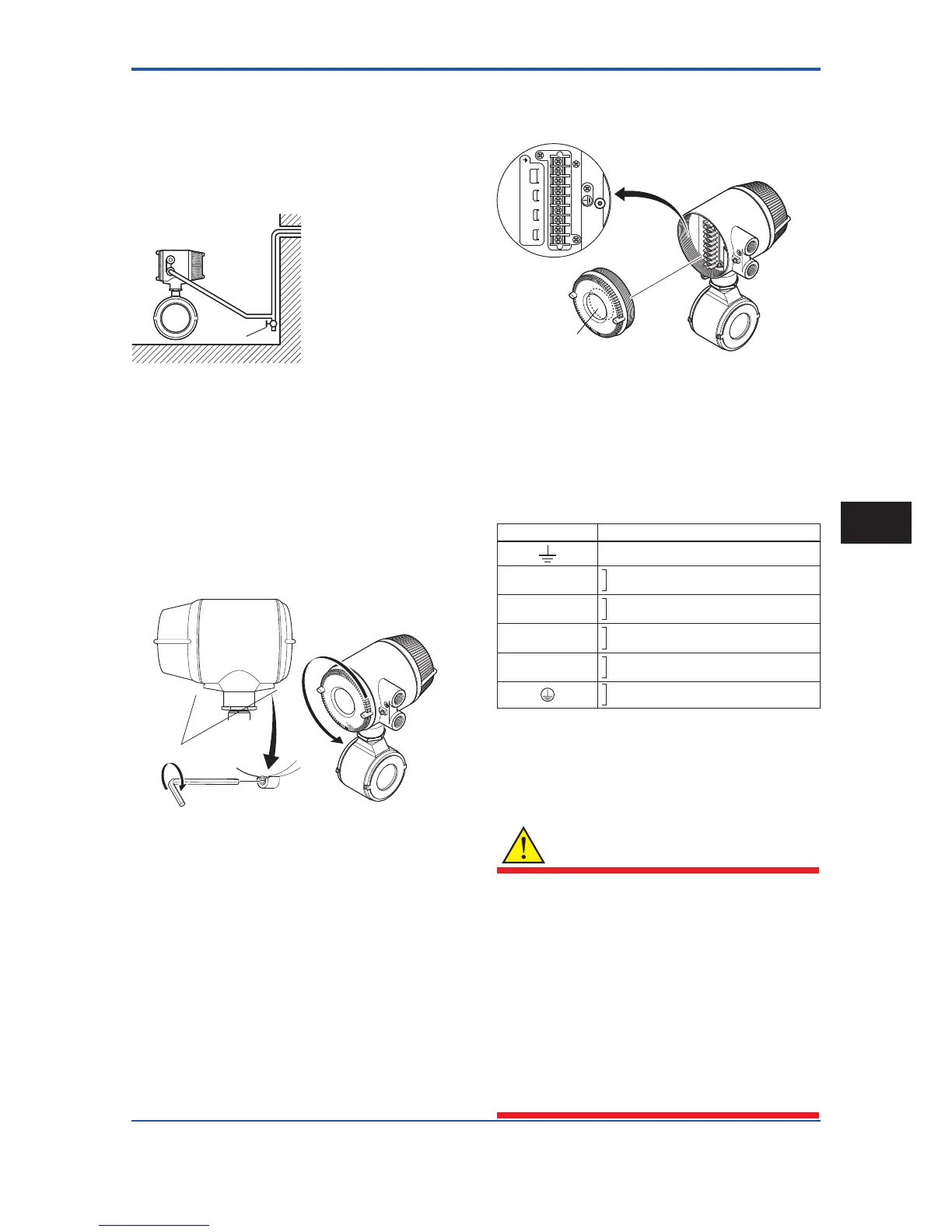

(1) Removing Cover

Loosen cover locking screw 2 clockwise using a

hexagonal wrench (nominal size 3) to unlock the cover.

(Upon shipment from the manufacturing plant, the cover

isunlocked.)Holdtheowmeterwithyourhandand

remove the cover by turning it in the direction of the arrow

as shown below.

Figure4.1.6 TerminalCongurationforIntegralFlowmeter

The description of the terminal symbols is shown in Table

4.1.1.

For F

OUNDATIONeldbusprotocol,refertoIM01E20F02-

01E.

For PROFIBUS PA protocol, refer to IM 01E20F12-01E.

Table 4.1.1 Terminal Symbols for Integral Flowmeter

Terminal Symbols Description

Functional grounding

N/–

L/+

Power supply

I+

I–

Current output 4 to 20mA DC

DO+

DO–

Pulse output/Alarm output/ Status output

DIO+

DIO–

Alarm output/Status output Status input

Protective grounding (Outside of the terminal)

(3) Precautions for Wiring of Power Supply

Cables

When connecting to the power supply, observe the points

below. Failure to comply with these warnings may result

in an electric shock or damage to the instrument.

WARNING

• Ensure that the power supply is OFF in order to

prevent electric shocks.

• Ensure the protective grounding terminal is

grounded before turning the power on.

• Use insulating sleeve crimp terminals (for 4-mm

screws) for the power supply wiring and protective

grounding wiring.

• Install an external switch or circuit breaker as a

means to turn the power off (capacitance; 15A,

conforming to IEC60947-1 and IEC60947-3).

Locate this switch either near the instrument or

inotherplacesfacilitatingeasyoperation.Afxa

“PowerOffEquipment”labeltothisexternalswitch

or circuit breaker.

Loading...

Loading...