<3. Installation>

32

IM01C25A01-01E

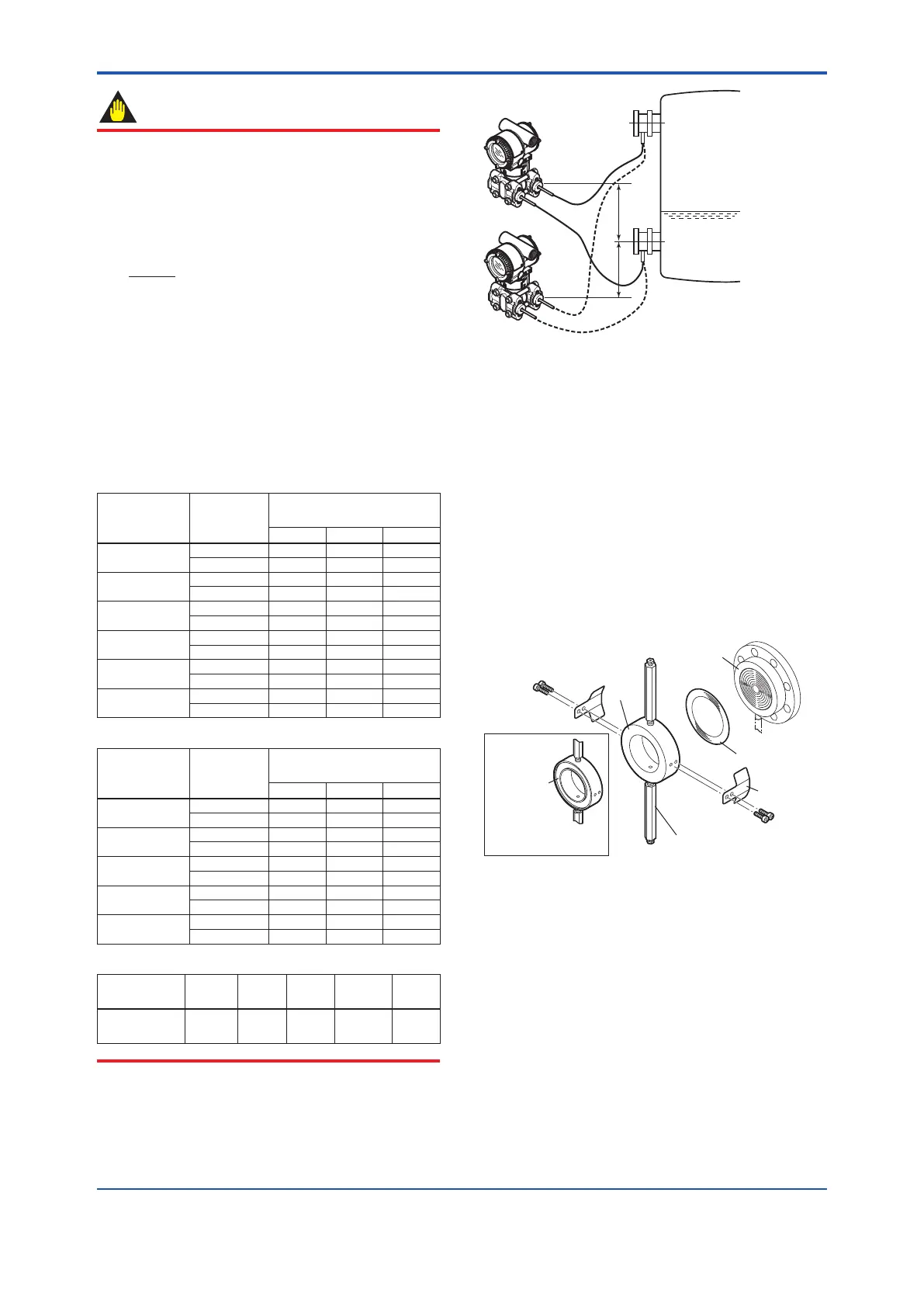

IMPORTANT

Thetransmittershouldbeinstalledatleast600mmbelow

thehighpressure(HP)processconnectiontoensurea

positiveheadpressureoflluid.Payspecialattentionto

vacuum applications.

Ifitcannotbeinstalledatleast600mmbelowtheHP

processconnection,pleaseusetheequationbelow:

h= × 0.102 [mm]

(P–P0)

ds

h: VerticalheightbetweentheHPprocessconnection

andthetransmitter(mm)

h≤0:Installthetransmitteratleasth(mm)belowthe

HP process connection

h>0:Installthetransmitteratmosth(mm)abovethe

HP process connection

P: Pressureinthetank(Paabs)

P0:Minimumworkingpressurelimitofthetransmitter(Pa

abs)Seebelowtable.

[ForlluidcodeA,B,C,D,E]

Wetted parts

material

code

Capillary

length

Process connection size

code

2, 8 3 4,W

SW

1 to 5m 6790 3190

6 to 10m 10030 3520

SE

1 to 5m 6790 3190

6 to 10m 10030 3520

SY

1 to 5m 3190

6 to 10m 3520

HW

1 to 5m 19150 6140

6 to 10m 8290

TW

1 to 5m 9620 3620

6 to 10m 4210

UW

1 to 5m 9540 4750

6 to 10m 6050

[Forlluidcode1,2,4]

Wetted parts

material

code

Capillary

length

Process connection size

code

2, 8 3 4,W

SW

1 to 5m 2570 320

6 to 10m 4680 530

SE

1 to 5m 2570 320

6 to 10m 4680 530

SY

1 to 5m 320

6 to 10m 530

HW

1 to 5m 10220 2050

6 to 10m 3450

TW

1 to 5m 4270 570

6 to 10m 960

ds:Specicgravityoflluid(at25°C).Seebelowtable.

Filluid

code

A, 1, 4 B C, 2 D E

ds:Specic

gravity

1.07 0.94 1.09

1.90 to

1.92

1.09

F0308.ai

P

Low pressure side

High

pressure

side

(+)

(–)

0

h

Figure 3.8 Example of Installation to Tank

(Caution on Installation)

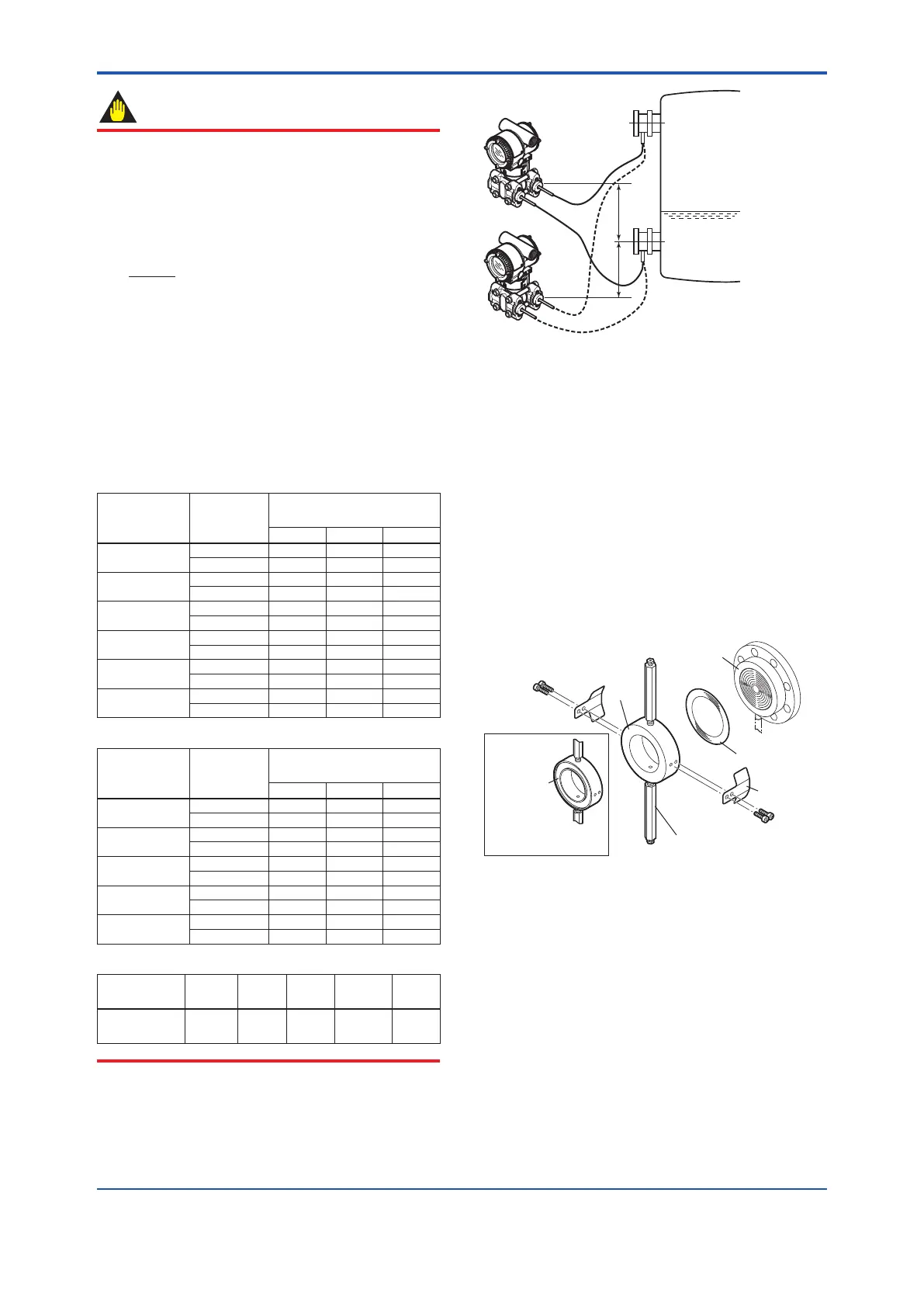

3.4 Mounting the Flushing

Connection Ring

3.4.1 Mounting to Pressure Detector

Section

Theushingconnectionringismountedtothepressure

detectorsectionasshowninFigure3.9.

Atthefactoryshipment,theushingconnectionringis

alreadyassembledandattachedtoprocessdetector

section.

Ring holder

Spiral gasket

F0309.ai

View from pressure

detector section

Groove for

installing

spiral gasket

Pressure-detector section

Vent/Drain plug

Ring

Figure 3.9 Mounting to Pressure Detector Section

(1)Mounttheringholderontheringandlooselytighten

themountingscrews.

(2)Placethespiralgasketintheringgroove.Withthe

ringcorrectlyalignedandushwiththefaceofthe

pressuredetector,securelytighteneachringholder’s

mounting screws.

(3)Positiontheringsothatthevent/drainplugsare

alignedstraightupanddown.

Loading...

Loading...