<4. Installing Impulse Piping>

35

IM01C25A01-01E

4. Installing Impulse Piping

4.1 Impulse Piping Installation

Precautions

Theimpulsepipingthatconnectstheprocess

outputstothetransmittermustconveytheprocess

pressureaccurately.If,forexample,gascollectsin

aliquid-lledimpulseline,orthedrainofagas-lled

impulselinebecomesplugged,itwillnotconveythe

pressureaccurately.Sincethiswillcauseerrorsinthe

measurementoutput,selecttheproperpipingmethod

fortheprocessuid(gas,liquid,orsteam).Paycareful

attentiontothefollowingpointswhenroutingtheimpulse

pipingandconnectingtheimpulsepipingtoatransmitter.

4.1.1 Connecting Impulse Piping to the

Transmitter

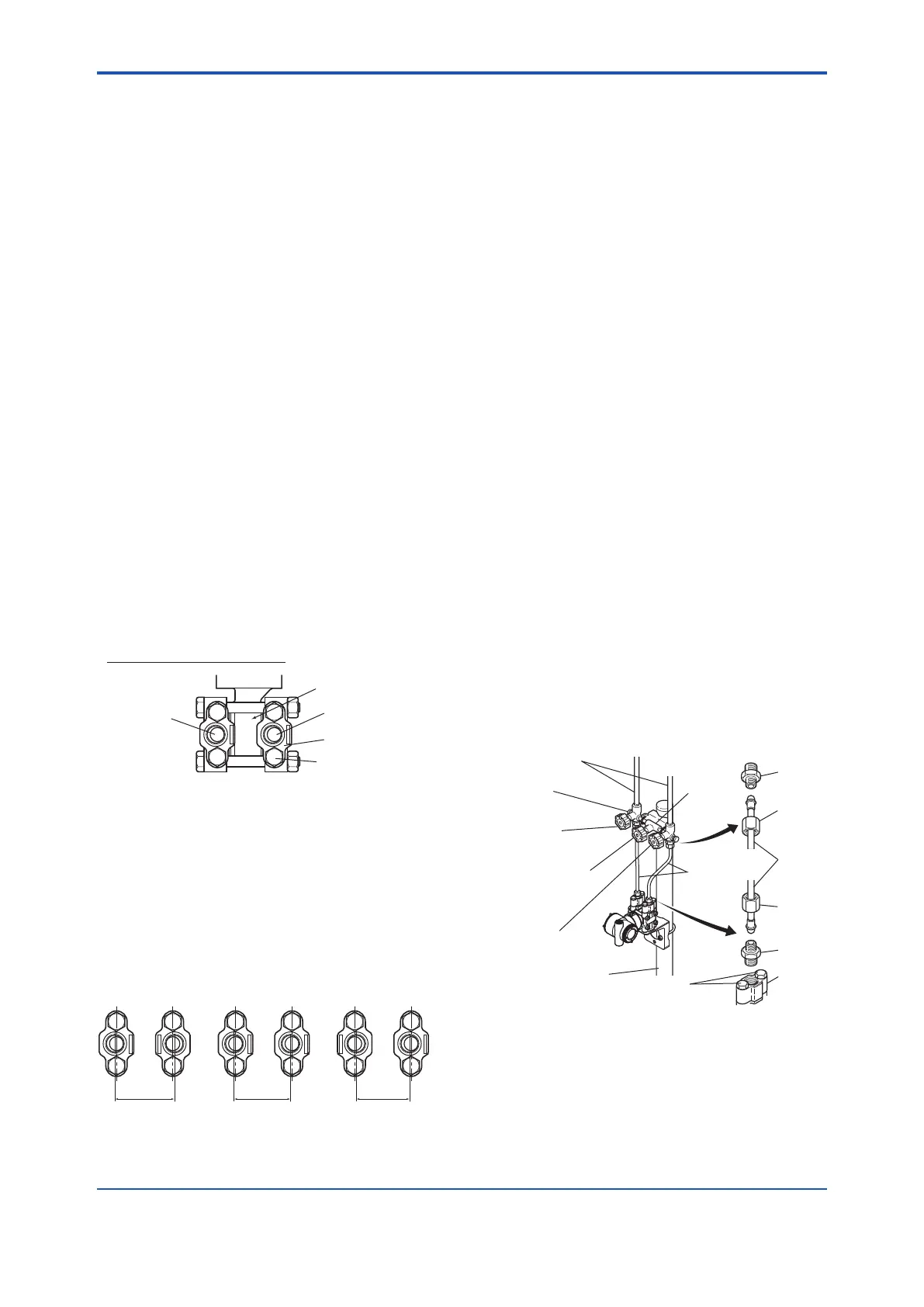

(1) Check the High and Low Pressure

Connections on the Transmitter (Figure 4.1)

Symbols“H”and“L”havebeenplacedonthecapsule

assemblytoindicatehighandlowpressureside.With

differentialpressuretransmitters,connectthehigh

pressuresideimpulselinetothe“H”side,andthelow

pressuresideimpulselinetothe“L”side.

Withgauge/absolutepressuretransmitters,connectthe

impulselinetothe‘H’side.

F0401.ai

Process

connection

“H” and “L” are shown

Process connection

Process connector

Bolt

Differential Pressure Transmitter

Figure 4.1 “H” and “L” Symbols on a Capsule

Assembly

(2) Changing the Process Connector Piping

Connections (for differential pressure

transmitters)

Theimpulsepipingconnectiondistancescanbechanged

between51mm,54mmand57mmbychangingthe

orientationoftheprocessconnectors.

Thisisconvenientforaligningtheimpulselinewitha

process connectors.

57 mm 54 mm 51 mm

F0402.ai

Figure 4.2 Process Connector Impulse Piping

Connection Distances

(3) Tightening the Process Connector

Mounting Bolts

Afterconnectinganimpulseline,tightentheprocess

connectormountingboltsuniformly.

(4) Removing the Impulse Piping Connecting

Port Dustproof Cap

Theimpulsepipingconnectingportonthetransmitteris

coveredwithaplasticcaptokeepoutdust.Thiscapmust

beremovedbeforeconnectingtheline.(Becarefulnot

todamagethethreadswhenremovingthiscap.Never

insertascrewdriverorothertoolbetweenthecapand

portthreadstoremovethecap.)

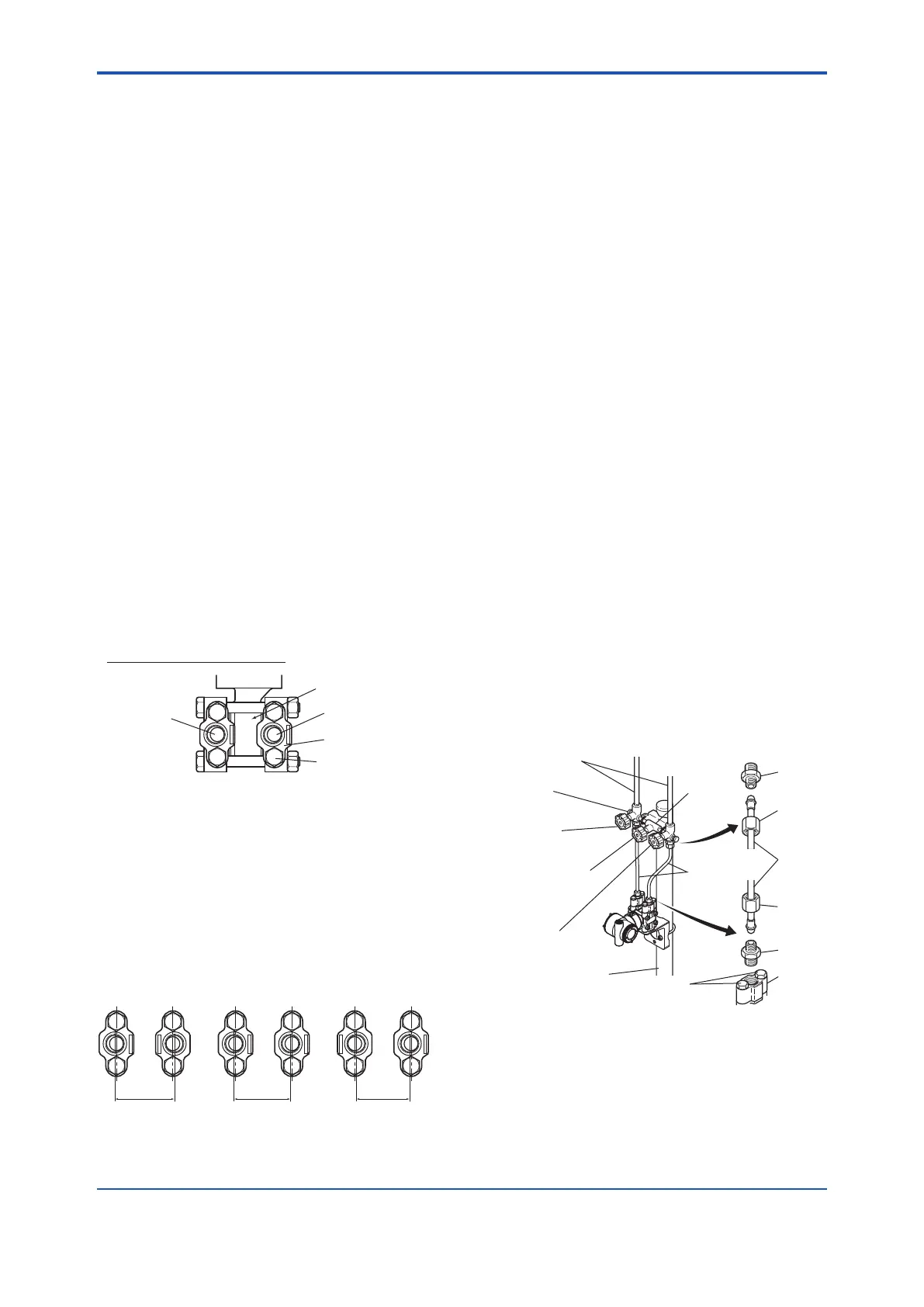

(5) Connecting the Transmitter and 3-Valve

Manifold (for differential pressure

transmitters)

A3-valvemanifoldconsistsoftwostopvalvestoblock

processpressureandanequalizingvalvetoequalize

thepressuresonthehighandlowpressuresidesofthe

transmitter.Suchamanifoldmakesiteasiertodisconnect

thetransmitterfromtheimpulsepiping,andisconvenient

whenadjustingthetransmitterzeropoint.

Therearetwo3-valvemanifoldtyps:thepipe-mounting

typeandthedirect-mountingtype;careshouldbetaken

withrespecttothefollowingpointswhenconnectingthe

manifoldtothetransmitter.

Pipe-Mounting Type 3-Valve Manifold

F0403.ai

Nipple

Nipple

Process

connector

Ball head

lock nut

Pipe

Ball head

lock nut

Process

connector bolts

50 mm(2-inch) pipe

Pipes

3-valve

manifold

Impulse piping

Vent plug

(optional)

Stop valve

(low pressure side)

Equalizing valve

(balancing)

Stop valve

(high pressure side)

Figure 4.3 3-Valve Manifold (Pipe-Mounting Type)

Loading...

Loading...