<4. Installing Impulse Piping>

36

IM01C25A01-01E

1) Screwnipplesintotheconnectionportsonthe

transmittersideofthe3-valvemanifold,andinto

theimpulsepipingconnectingportsontheprocess

connectors.(Tomaintainpropersealing,windsealing

tapearoundthenipplethreads.)

2) Mountthe3-valvemanifoldonthe50mm(2-inch)

pipebyfasteningaU-bolttoitsmountingbracket.

TightentheU-boltnutsonlylightlyatthistime.

3) Installthepipeassembliesbetweenthe3-valve

manifoldandtheprocessconnectorsandlightly

tightentheballheadlocknuts.(Theball-shapedends

ofthepipesmustbehandledcarefully,sincetheywill

notsealproperlyiftheballsurfaceisscratchedor

otherwisedamaged.)

4) Nowtightenthenutsandboltssecurelyinthe

followingsequence:

Processconnectorbolts→transmitter-endballhead

locknuts→3-valvemanifoldballheadlocknuts→

3-valvemanifoldmountingbracketU-boltnuts

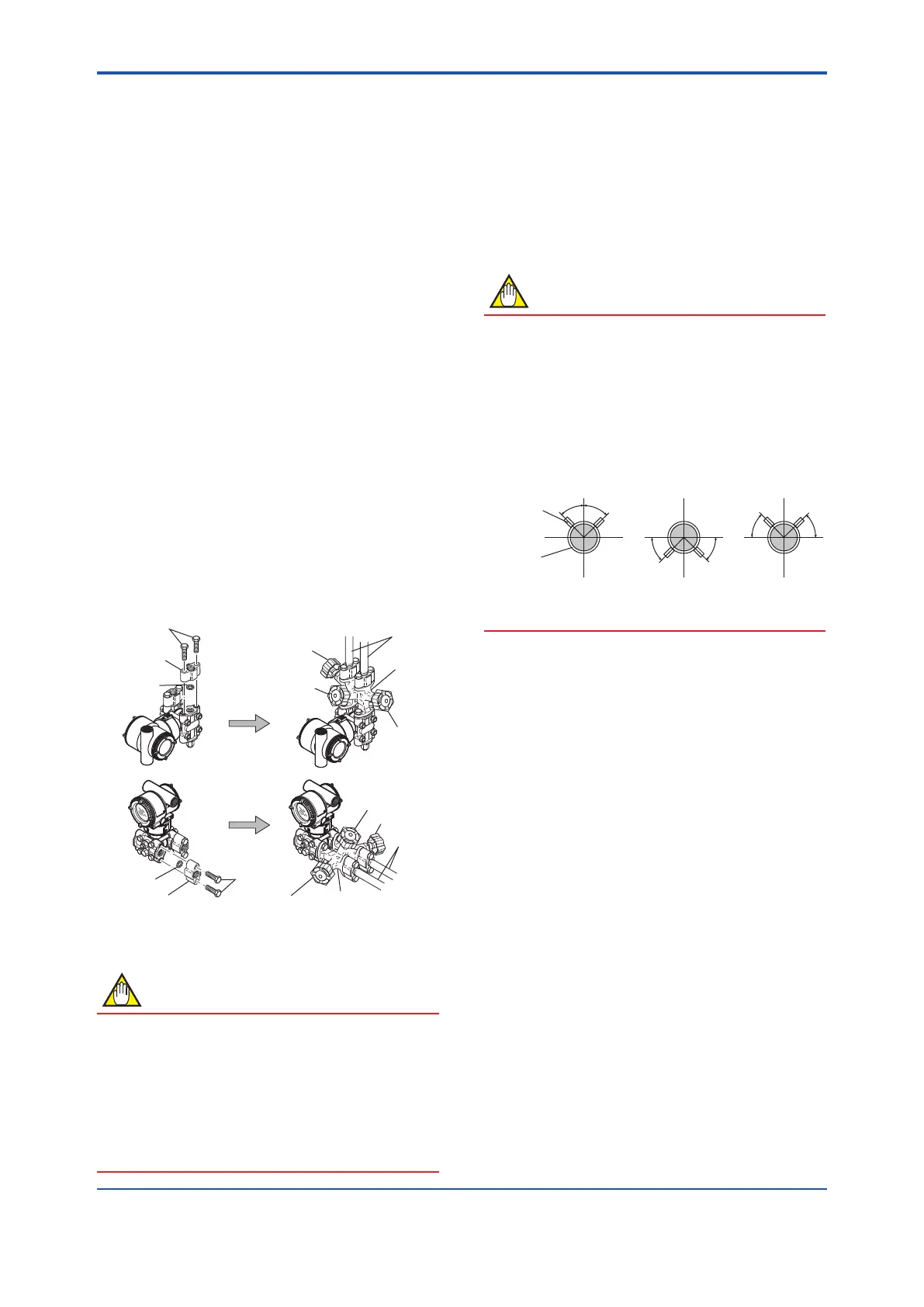

Direct-Mounting Type 3-Valve Manifold

1) Mountthe3-valvemanifoldonthetransmitter.(When

mounting,usethetwogasketsandthefourbolts

providedwiththe3-valvemanifold.Tightenthebolts

evenly.)

2) Mounttheprocessconnectorsandgasketsonthetop

ofthe3-valvemanifold(thesideonwhichtheimpulse

pipingwillbeconnected.)

Bolts

Process

connector

Gasket

Gasket

Process

connector

Bolts

Stop valve

Stop valve

3-valve

manifold

3-valve

manifold

Equalizing valve

Equalizing

valve

Stop valve

Impulse

piping

Impulse

piping

Stop valve

F0404.ai

Figure 4.4 3-Valve Manifold (Direct-Mounting Type)

NOTE

Aftercompletingtheconnectionofthetransmitterand

3-valvemanifold,besuretoCLOSEthelowpressure

andhighpressurestopvalves,OPENtheequalizing

valve,andleavethemanifoldwiththeequalizingvalve

OPEN.

Youmustdothisinordertoavoidoverloadingthe

transmitterfromeitherthehighorthelowpressure

sidewhenbeginningoperation.

4.1.2 Routing the Impulse Piping

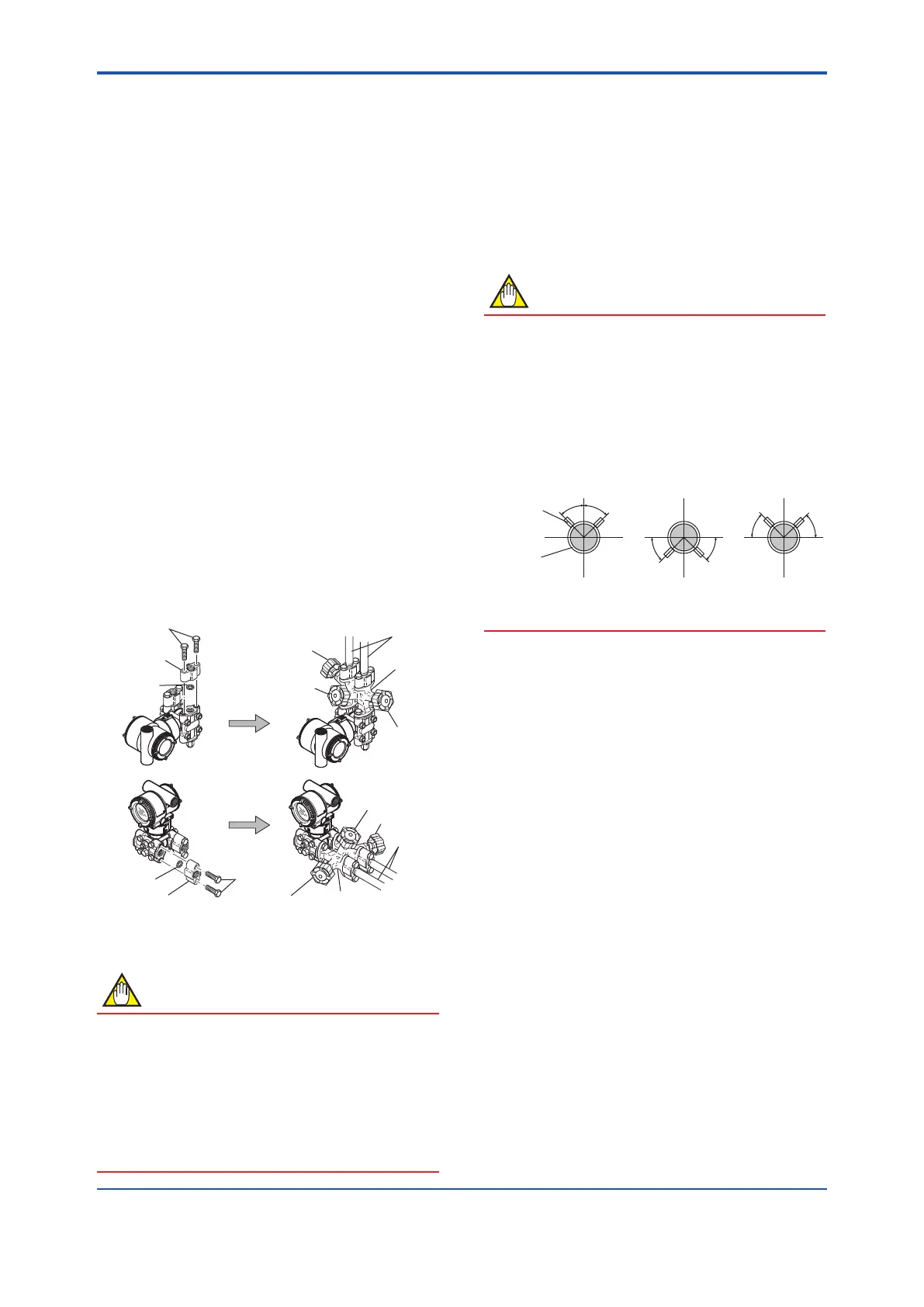

(1) Process Pressure Tap Angles

Ifcondensate,gas,sedimentorotherextraneous

materialintheprocesspipinggetsintotheimpulse

piping,pressuremeasurementerrorsmayresult.To

preventsuchproblems,theprocesspressuretapsmust

beangledasshowninFigure4.5accordingtothekindof

uidbeingmeasured.

NOTE

• Iftheprocessuidisagas,thetapsmustbe

verticalorwithin45°eithersideofvertical.

• Iftheprocessuidisaliquid,thetapsmustbe

horizontalorbelowhorizontal,butnotmorethan

45°belowhorizontal.

• Iftheprocessuidissteamorothercondensing

vapor,thetapsmustbehorizontalorabove

horizontal,butnotmorethan45°abovehorizontal.

[Gas]

Pressure

taps

Process

piping

[Steam][Liquid]

45°

45°

45° 45°

45°

45°

F0405.ai

Figure 4.5 Process Pressure Tap Angle

(For Horizontal Piping)

(2) Position of Process Pressure Taps and

Transmitter

Ifcondensate(orgas)accumulatesintheimpulsepiping,

itshouldberemovedperiodicallybyopeningthedrain

(orvent)plugs.However,thiswillgenerateatransient

disturbanceinthepressuremeasurement,andtherefore

itisnecessarytopositionthetapsandroutetheimpulse

pipingsothatanyextraneousliquidorgasgeneratedin

theleadlinesreturnsnaturallytotheprocesspiping.

• Iftheprocessuidisagas,thenasarulethe

transmittermustbelocatedhigherthantheprocess

pressure taps.

• Iftheprocessuidisaliquidorsteam,thenasa

rulethetransmittermustbelocatedlowerthanthe

process pressure taps.

(3) Impulse Piping Slope

Theimpulsepipingmustberoutedwithonlyanupwardor

downwardslope.Evenforhorizontalrouting,theimpulse

pipingshouldhaveaslopeofatleast1/10toprevent

condensate(orgases)fromaccumulatinginthepipes.

Loading...

Loading...