<4. Installing Impulse Piping>

38

IM01C25A01-01E

F0408.ai

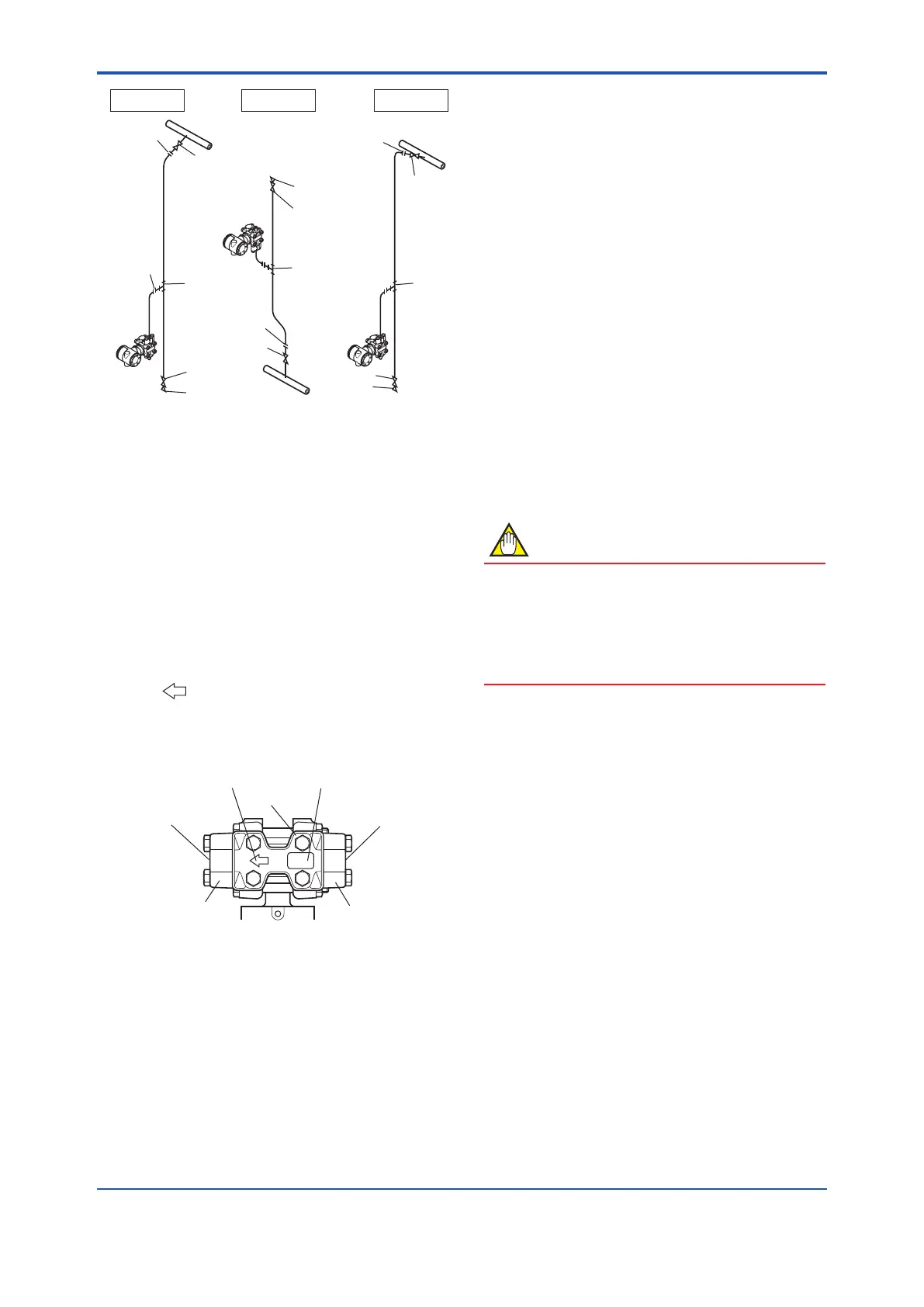

Liquid

Gas Steam

Union or flange

Tee

Tee

Drain plug

Drain valve

Drain valve

Drain plug

Union or flange

Union or

flange

Union or flange

Tap valve

Tap valve

Tee

Drain valve

Drain plug

Tap valve

Figure 4.8 Impulse Piping Connection Examples

(for gauge/absolute pressure

transmitters)

4.3 Process Piping Installation

Precautions (EJ115)

4.3.1 Connecting Process Piping to the

Transmitter

(1) ConrmingtheProcessFluidFlow

Direction

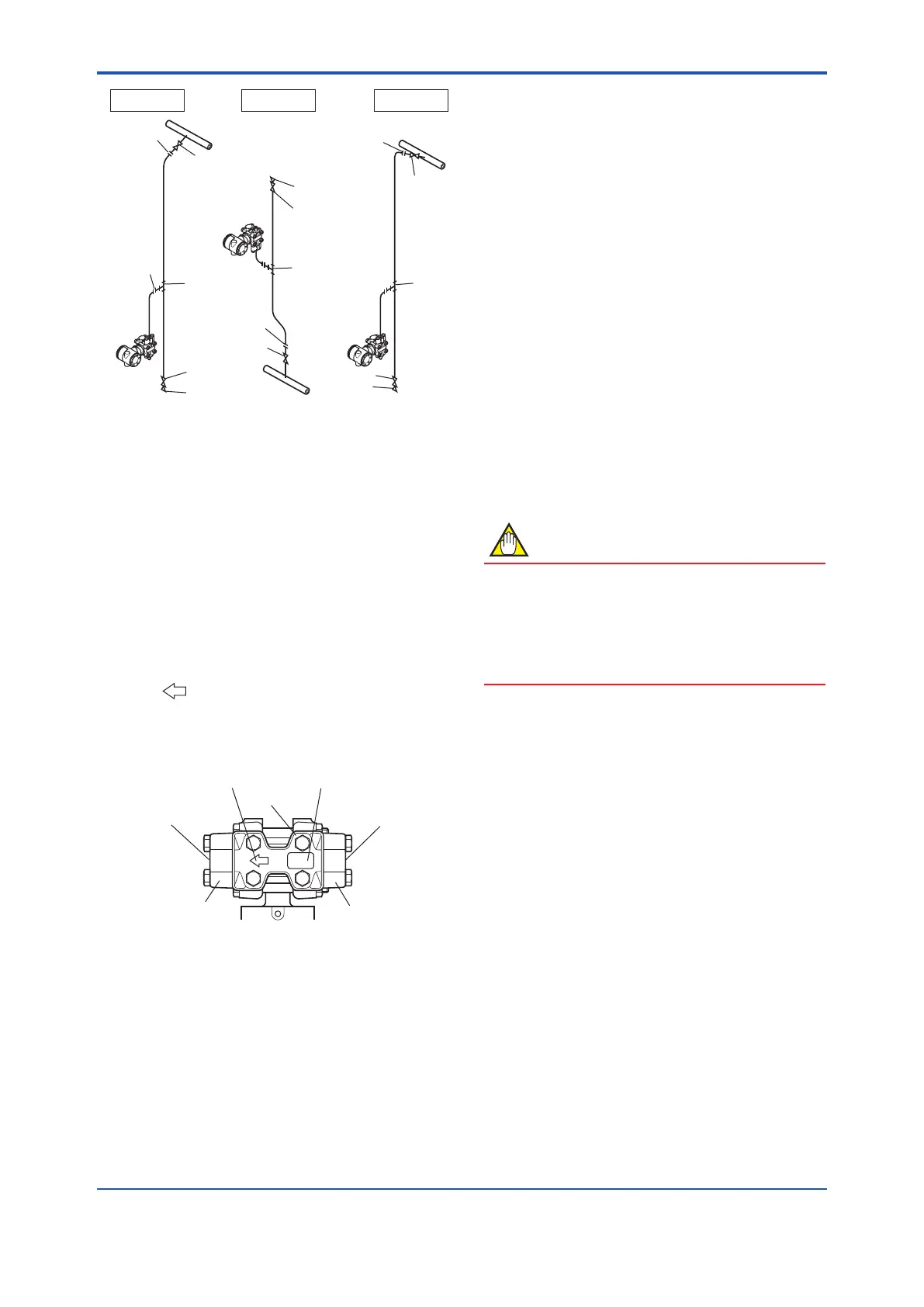

Themark“ ”onthemanifoldindicatesthedirectionin

whichtheprocessuidisowed(fromrighttoleft).

Whenconnectingtheprocesspipingtotheprocess

connector,conrmtheprocessuidowdirection.

F0409.ai

Flow direction (from right to left)

Manifold

Orifice name plate

Process connector

(low pressure side)

Process connector

(high pressure side)

Process connection

(outflow side)

Process connection

(inflow side)

Figure 4.9 Manifold and Flow Direction Indication

(2) Tightening the Process Connector

Mounting Bolts

Thetransmitterisshippedwiththeprocessconnector

mountingboltsonlylooselytightened.Afterconnecting

theprocesspiping,tightentheseboltsuniformlyto

preventleakswithatorqueof39to49N·m{4to5kgf·m}.

(3) Removing the Process Connector Port

Dustproof Cap

Theprocessconnectorportthreadsarecoveredwitha

plasticcaptoexcludedust.Thiscapmustberemoved

beforeconnectingthepiping.(Becarefulnottodamage

thethreadswhenremovingthiscap.Neverinserta

screwdriverorothertoolbetweenthecapandport

threadstoremovethecap.)

4.3.2 Routing the Process Piping

(1) Relationship between Process Fluid

and Manifold Locations (For the vertical

impulse piping type)

Ifcondensate(orgas)generatedintheprocesspiping

wereallowedtoaccumulate,thenitwouldbenecessary

toremoveitperiodicallybyopeningthedrain(or

vent)plug.However,thiswouldgenerateatransient

disturbanceinthepressuremeasurement.Therefore,the

processpipingmustberoutedsothatanycondensate(or

gas)generatedintheprocesspipingwillnotaccumulate

inthepressure-sensingassemblyofthetransmitter.

NOTE

• Iftheprocessuidisagas,thenasarulethe

manifoldmustbelocatedatthedownsideofthe

pressure-sensingassembly.

• Iftheprocessuidisaliquid,thenasarulethe

manifoldmustbelocatedattheupsideofthe

pressure-sensingassembly.

(2) Pipe Size for Process Piping

Usea15mm(1/2-inch)pipeforprocesspiping

connectiontotheprocessconnector.

(3) Preventing Freezing

Ifthereisanyriskthattheprocessuidinthetransmitter

pressure-sensingassemblycouldfreezeorsolidify,use

asteamjacketorheatertomaintainthetemperatureof

theuid.

(4) Process Piping Connection Examples

Figure4.10showsexamplesoftypicalprocesspiping

connections.Beforeconnectingthetransmittertothe

process,studythetransmitterinstallationlocation,the

processpipinglayout,andthecharacteristicsofthe

processuid(corrosiveness,toxicity,ammability,etc.),in

ordertomakeappropriatechangesandadditionstothe

connectioncongurations.

Notethefollowingpointswhenreferringtothesepiping

examples.

• Theprocesspipingmaterialusedmustbecompatible

withtheprocesspressure,temperature,andother

conditions.

Loading...

Loading...