<3. Installation>

33

IM01C25A01-01E

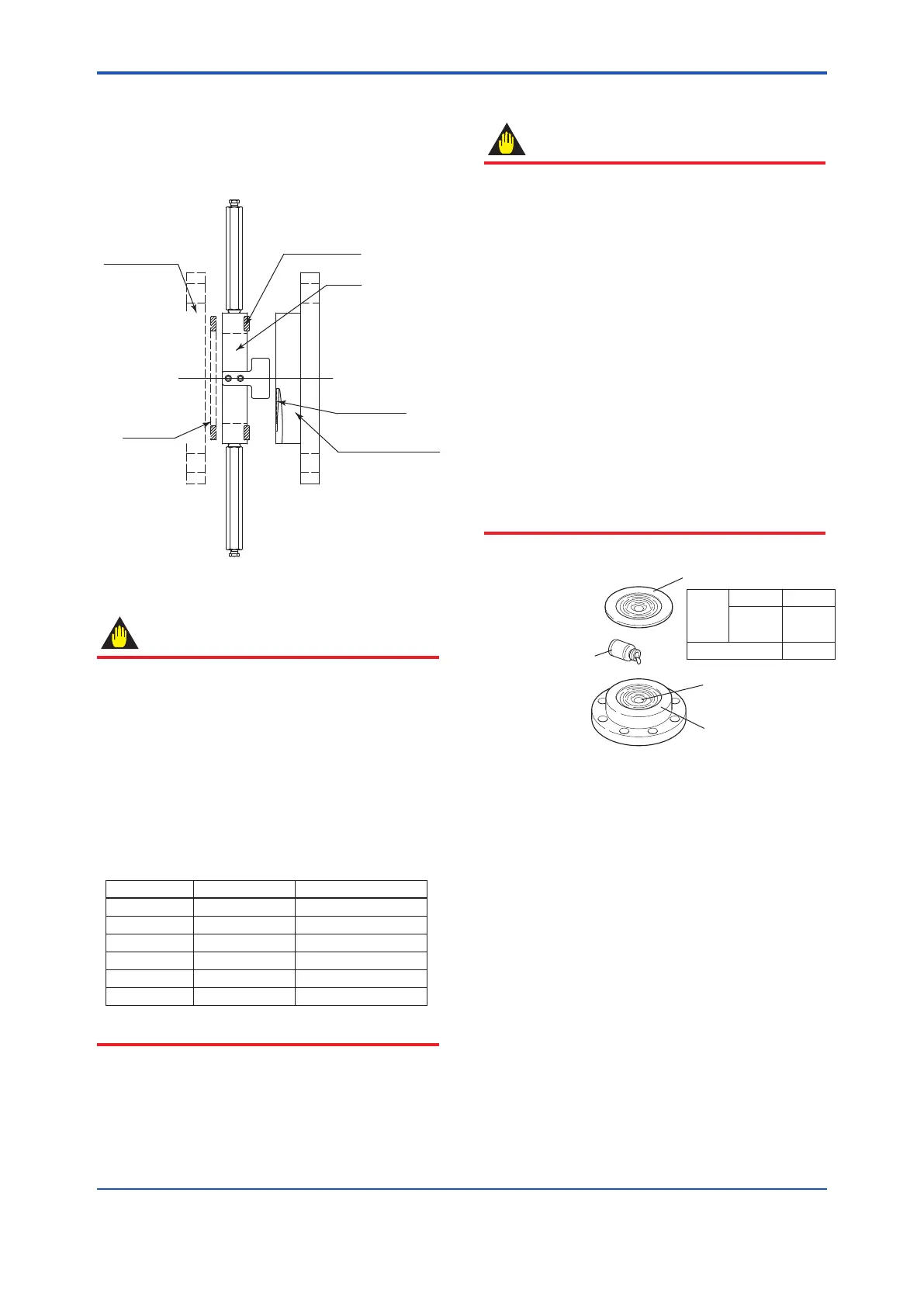

3.4.2 Mounting to Process Flange

Tightentheboltstocompletelyclosethegapbetweenthe

ringandthepressuredetectorsection.

Thematingange,gasket,studboltsandnutsareto

procuredbythecustomer.

F0310.ai

Ring

Diaphragm

Pressure-detector

section

Gasket

Mating flange

Spiral gasket

Figure 3.10 Mounting to Process Flange

IMPORTANT

• Conrmthatthereisnogapbetweenthering

andtheprocess-detectorsectionaftertheyare

mountedontheprocessange.Agapcanleadto

asudden,explosivereleaseofprocessuids.

• Whenmountingorremovingthering,takecarenot

totiltthepressuredetectordownwardasthering

can slip off and cause injury.

• Whenre-mountingthering,usethenewspiral

gasketasshowninbelowtable.

Table 3.1 Spiral Gasket for Pressure Detector

Section Side*

Part number Size Description

F9350SV ø100×ø120×t4.5 For3-inchange

F9970XF ø100×ø120×t4.5 For3-inchange**

F9350ST ø70×ø90×t4.5 For2-inchange

F9970XD ø70×ø90×t4.5 For2-inchange**

F9346ZH ø60×ø75×t4.5 For11/2-inchange

F9970XB ø60×ø75×t4.5 For11/2-inchange**

*: Material;316SST(Hoop),PTFETeon(Filler)

**: Foroil-prohibiteduse(Optioncode:/K1,/K2,/K5,/K6)

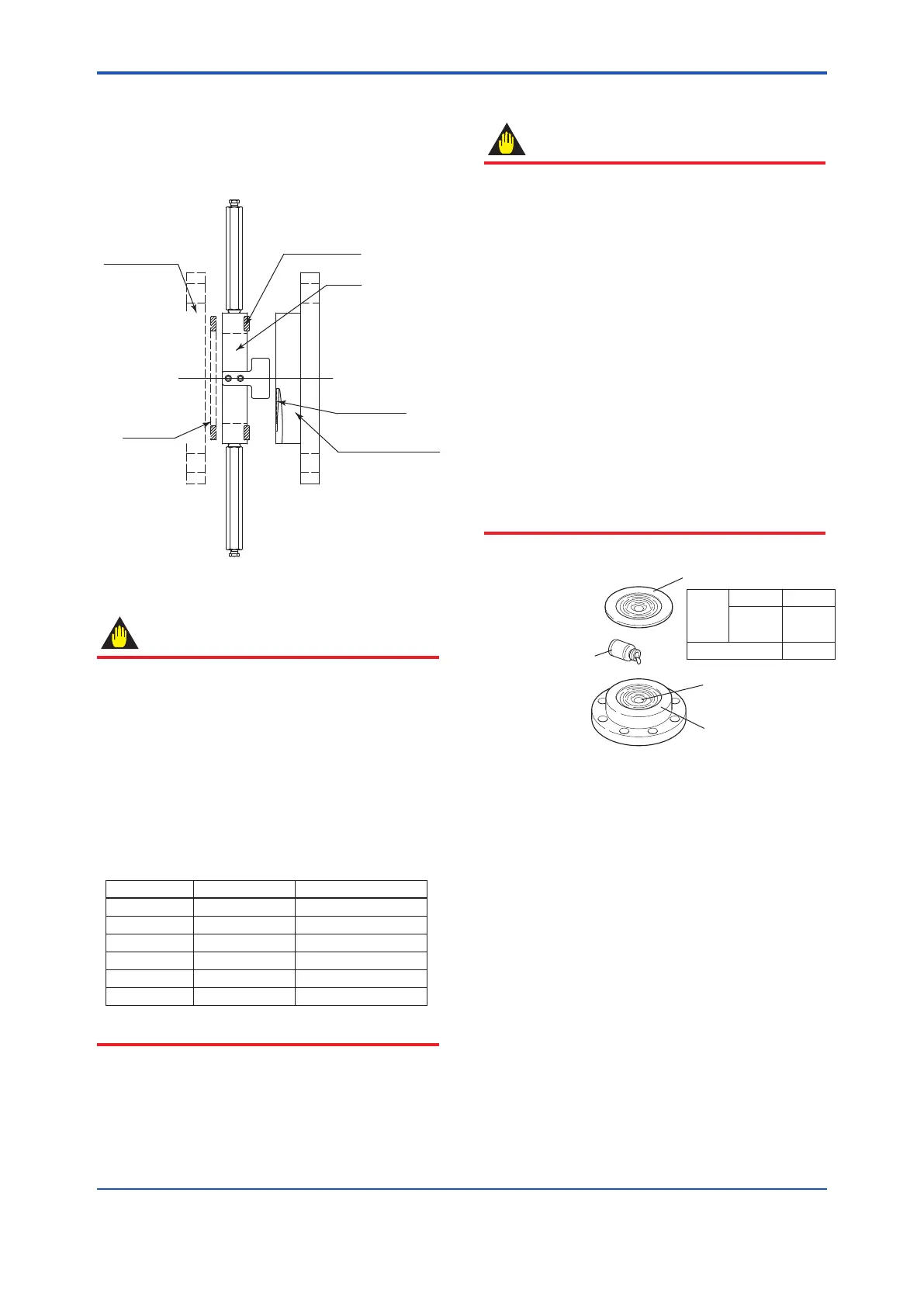

3.5 AfxingtheTeonFilm

IMPORTANT

TheFEPTeflonoptionincludesateflonfilmand

fluorinatedoil.Beforemountingthetransmittertothe

processange,afxtheteonlmasfollows:

1)Positionthediaphragmsealsothatthediaphragm

is in an upward position.

2)Pourtheuorinatedoilonthediaphragmand

gasketareacoveringitcompletelyandevenly.Be

carefulnottoscratchthediaphragmorchangethe

itsshape.

3)Afxtheteonlmoverthediaphragmandgasket

area.

4)Next,carefullyinspectthecoverandtrytoidentify

anyentrappedairbetweenthediaphragmand

theteonlm.Theairmustberemovedtoensure

optimumperformance.Ifairpocketsarepresent,

useyourngerstoremovetheairbystartingatthe

centerofthediaphragmandworkyourwayout.

5)PositionthegasketontheTeonlm.

6)Mountthetransmitterontotheprocessange.

F0311.ai

EJ210 F9347YD

EJ118

EJ438

F9347YA

2 inch

F9347XA3 inch

Teflon film

PART No.

Diaphragm

Fluorinated oil

[PART No. : F9145YN]

Gasket area

Figure3.11 AfxingtheTeonFilm

Loading...

Loading...