3. INSTALLATION

3.1 Installation Precautions

(1) Ambient Temperature

Avoid locations that are subjected to considerable

temperature variations and uctuations. When the

installation site is subjected to heat radiation from

the plant, adopt insulation measures or ensure

adequate ventilation.

(2) Atmospheric Conditions

Avoid installing the vortex owmeter in a corrosive

atmosphere. When the vortex owmeter must be

installed in a corrosive atmosphere, take measures

to ensure adequate ventilation, and prevent the

entry or build-up of rain water in wiring ducts.

(3) Mechanical Shock or Vibration

The vortex owmeter has been designed to be a

strong structure. However, install it at a location

that is subjected to minimal mechanical shock or

vibration.

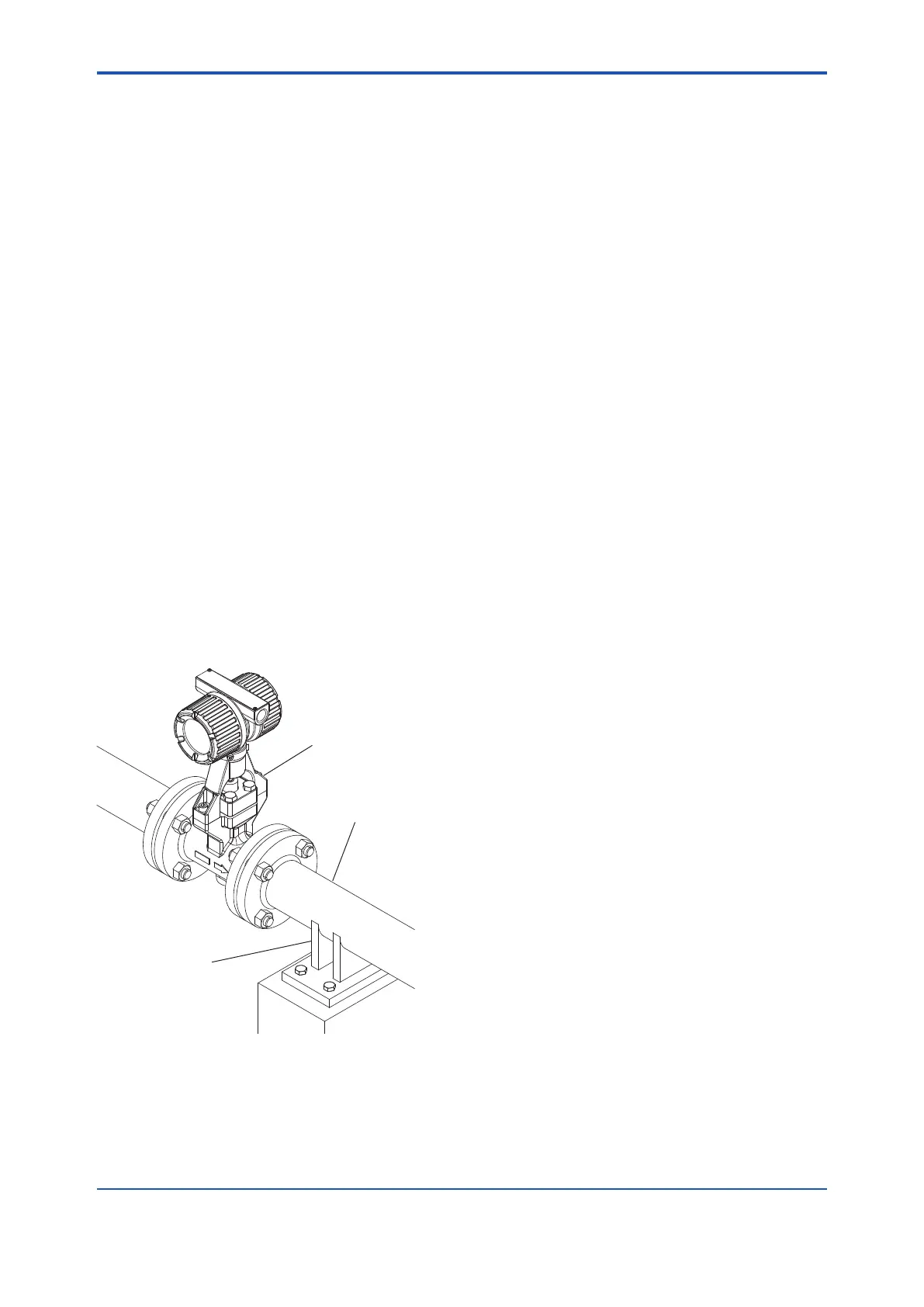

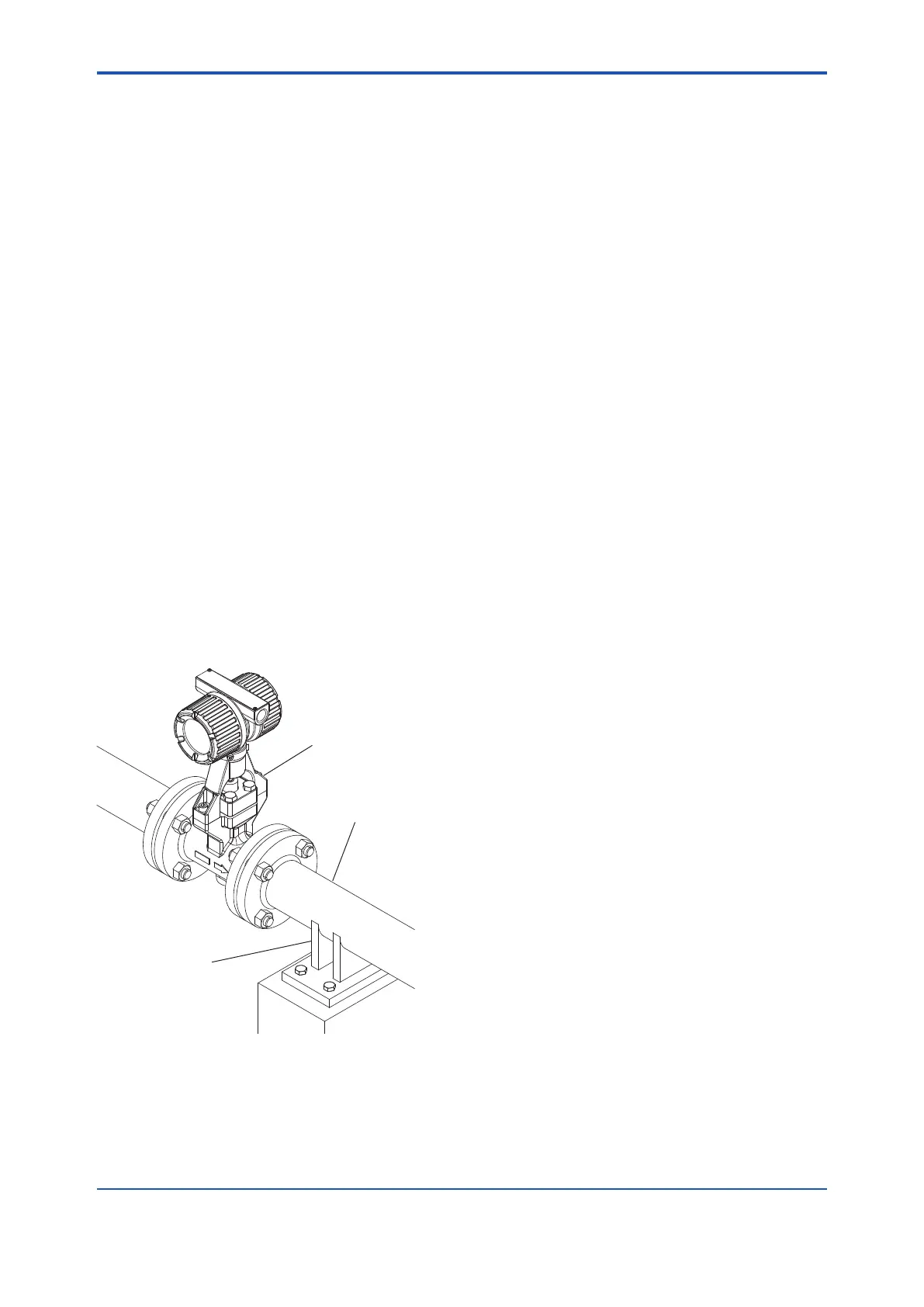

If the owmeter is subjected to vibrations, it is

recommended that pipeline supports are provided

as shown in Figure 3.1.

Vortex Flowmeter

Piping line

Piping support

F0301.ai

Figure 3.1 Example of Pipeline Support

(4) Piping Line

When passing uids along the piping line of the

vortex owmeter, pay attention to the following

points to ensure safe and accurate use.

(a) Make sure that the connector bolts for installing the

vortex owmeter and piping line are tightened rmly.

(b) Make sure that there are no leaks on the piping.

(c) Do not apply a pressure higher than the specied

maximum working pressure.

(d) Do not loosen or tighten the ange mounting bolts

when the assembly is pressurized. Be sure to

depressurize the piping line before doing this.

(e) Handle the vortex owmeter carefully when

measuring toxic liquids, so that the liquids do not

splash into the eyes or face. When using toxic gases,

be careful not to inhale them.

(5) Other

• Choose a location where there is sucient

clearance around the vortex owmeter to allow

work such as routine inspection.

• Choose a location that allows easy wiring and

piping.

<3. Installation>

10

IM 01F07A01-01EN

Loading...

Loading...