31

11.2.4. Package MedicalDevices

1. Place the device in ethylene oxide (EO) compatiblepackaging.

2. Place one or more EO chemical indicators (CI) inside each container, wrapped tray, or sterilization pouch (Chapter 13: Process Monitoring, Load Release, and SterilizerQualification).

3. When sterilizing pouched items, seal the sterilization pouch using a heat sealer set to the appropriate time andtemperature or seal with the self-adhesive tab per the pouch manufacturer’s

instructions per use (IFU).

4. Wrap non-containerized trays with EO compatible wrapping material and secure with EO indicatortape.

5. For containerized items, ensure an external chemical indicator for EO ispresent.

NOTE: When loading devices inside a container or tray, leave sufficient space between the instruments to enable the sterilant to circulate. The containers used must be prepared and sealed

according to the procedures recommended by their respectivemanufacturers.

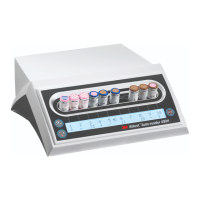

11.3. Loading the 3M™Steri-Vac™ Sterilizer/Aerator GSSeries

Loading baskets are recommended to facilitate loading the sterilization chamber. Loading baskets are designed with skids to avoid scratching the chamber floor. A transport cart can be used to

easily load, unload, and move loading baskets to and from the 3M™Steri-Vac™ Sterilizer/Aerator GSSeries.

DANGER: To reduce the risks associated with exposure to ethyleneoxide,

do not overload the sterilization chamber. Use good practices for loading the 3M™Steri-Vac™ Sterilizer/Aerator GS Serieschamber.

CAUTION: To reduce the risk ofinjury,

follow good ergonomic practices. Loading baskets should not be overfilled requiring excessive force in pulling and pushing loaded baskets in and out of the 3M™Steri-Vac™ Sterilizer/Aerator

GS Series chamber. Reference facility policies and procedures for appropriate ergonomic practices.

CAUTION: To reduce patient risks associated with exposure to potentially non-sterile devices or inadequate sterilizationprocedures:

Always use chemical indicators and biological indicators for monitoring the performance of sterilization cycles as described in this manual. Always use chemical indicators and biological

indicators per the device manufacturer’s instructions for use(IFU).

Do not overload the sterilization chamber. Use good practices for loading the 3M™Steri-Vac™ Sterilizer/Aerator GS Serieschamber.

11.3.1. LoadingRecommendations

Biological indicators, such as the 3M™ Attest™ Biological Indicators for ethylene oxide, in a routine biological indicator process challenge device (PCD, also known as a Test Pack or BI PCD)

should be used in every load. A BI PCD such as 3M™ Attest™ Biological Indicator Test Pack for EO or 3M™ Attest™ Rapid Readout Biological Indicator Test Pack for EO should be placed in

the center of the load (Chapter 13: Process Monitoring, Load Release, and SterilizerQualification).

• Always use loading baskets when loading the 3M™Steri-Vac™ Sterilizer/Aerator GSSeries.

• Do not overload the GS Series sterilizer. Arrange items in the loading baskets to ensure that water vapor and ethylene oxide (EO) can circulate freely betweenthem.

• Place peel pouches on their edges, ifpossible.

• Arrange sterilization pouches so that the transparent side of a pouch faces the opaque side of the adjacentpouch.

• Ensure no devices are touching the GS Series sterilizer chamberwalls.

11.3.2. Loading Medical Devices andInstruments

Sterilization pouches should be placed on their edges if possible. If a sterilization pouch is placed on its side or flat on the shelf, do not place any item on top of thepouch.

To the extent practical, the Operator should attempt to sterilize full loads of items having a common aerationtime.

A full load can be comprised of sterilization pouches, wrapped trays, and containers or a combination of variouspacks.

NOTE: In the U.S., the Environmental Protection Agency (EPA) National Emission Standards for Hospital Ethylene Oxide Sterilizers requires hospitals that do not have an air pollution control device

to adopt the management practice of running full loads except under medically necessary circumstances. The date and time of all EO sterilization cycles should be documented and any

loads not containing a full load for medically necessary reasons should be noted. The rule does not require hospitals to purchase air pollution control devices. The use of an air pollution

control device, however, is an acceptable alternative to the managementpractice.

Loading...

Loading...