51

Stop

Sterilizer

Aeration time elapsed (hh:mm):

0:05

1:00

11:55

55.0

Menu

Menu

˚

C

04/20/2015

20:54:20

Gas expose time elapsed (hh:mm):

Cycle time remaining (hh:mm):

Cycle:

Stage:

Count:33

Aeration paused

Open door Show chart

98.0

kPa

55

˚

C

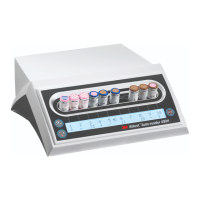

Figure60.

Aeration StagePaused

12.10. Empty 3M™ Steri-Gas™ EO GasCartridges

The 3M™ Steri-Gas™ EO Gas Cartridge should be aerated for a minimum of two hours before disposal. Cycles with two or more hours of aeration time will provide sufficient aeration as required

for a Steri-Gas EO Gas Cartridge. An empty cartridge will aerate while located inside the 3M™Steri-Vac™ Sterilizer/Aerators GS Series chamber cartridge bay. After aeration is complete,

remove the cartridge from the holder and dispose of the cartridge in a non-incinerated waste receptacle or recycle the cartridge per your facility’srequirement.

12.11. Aeration of a Biological Indicator Process ChallengeDevice(BIPCD)

The components of the biological indicator (BI) process challenge device (PCD, also known as a Test Pack) should also be aerated prior to disposal. A 3M branded BI PCD will normally be

sufficiently aerated with a load with two hours or greater aeration time. For other brands of BI PCDs, contact the manufacturer for recommended aeration time. Dispose of the BI PCD components

per manufacturer’s instructions for use(IFUs).

12.12. Sterilization CycleCancellations

12.12.1. Manual CycleCancellation

The Operator can manually interrupt a cycle at any time prior to ethylene oxide (EO) gas injection. If the sterilization cycle is manually cancelled any time after EO gas injection, the

3M™ Steri-Vac™ Sterilizer/Aerator GS Series will automatically proceed to or repeat EO Removal and Flushing stages to clear the chamber of EO gas before the door is unlocked. A manual

cycle interruption error message will appear on the display screen and cycle reports. On double door sterilizers, if a cycle is cancelled in any stage up to and including the Flushing stage, the

Load Door is the only door that the sterilizer will allow to be opened as the cycle is not considered complete. When the Flushing stage is complete, the Unload Door is the only door that the

system will allow to be opened to ensure that the load can only be accessed from the unload side of the sterilizer. Refer to Chapter 15: Cautions, Error Messages, and Troubleshooting for error

codes and their respective corrective actions.

12.12.2. Automatic CycleCancellation

The 3M™ Steri-Vac™ Sterilizer/Aerator GS Series may automatically cancel a cycle and progress to a safe error recovery stage if a fault condition is detected by the sterilizer. An error message

will be evident on the display screen and cycle reports. On double door sterilizers the Unload Door cannot be opened after an automatic cycle cancellation as the cycle is not considered

successfully complete. Refer to Chapter 15: Cautions, Error Messages, and Troubleshooting for error codes and their respective corrective actions.

12.13. PowerOutages

If a power outage occurs while a cycle is in progress, the 3M™Steri-Vac™ Sterilizer/Aerator GS Series will remain in a safestate.

When the power resumes, if critical cycle parameters monitored are still within acceptable limits for the specific stage of the cycle, the cycle will continue and a caution indication will appear on

both the display screen and the cycle report to notify the user that a power outageoccurred.

When the power resumes, if the critical parameters are outside acceptable limits, the cycle will automatically proceed to an error recovery state. A cycle error indication will appear on both the

display screen and the cycle report to notify the user. Refer to Chapter 15: Cautions, Error Messages, and Troubleshooting for error codes and their respective correctiveactions.

Loading...

Loading...