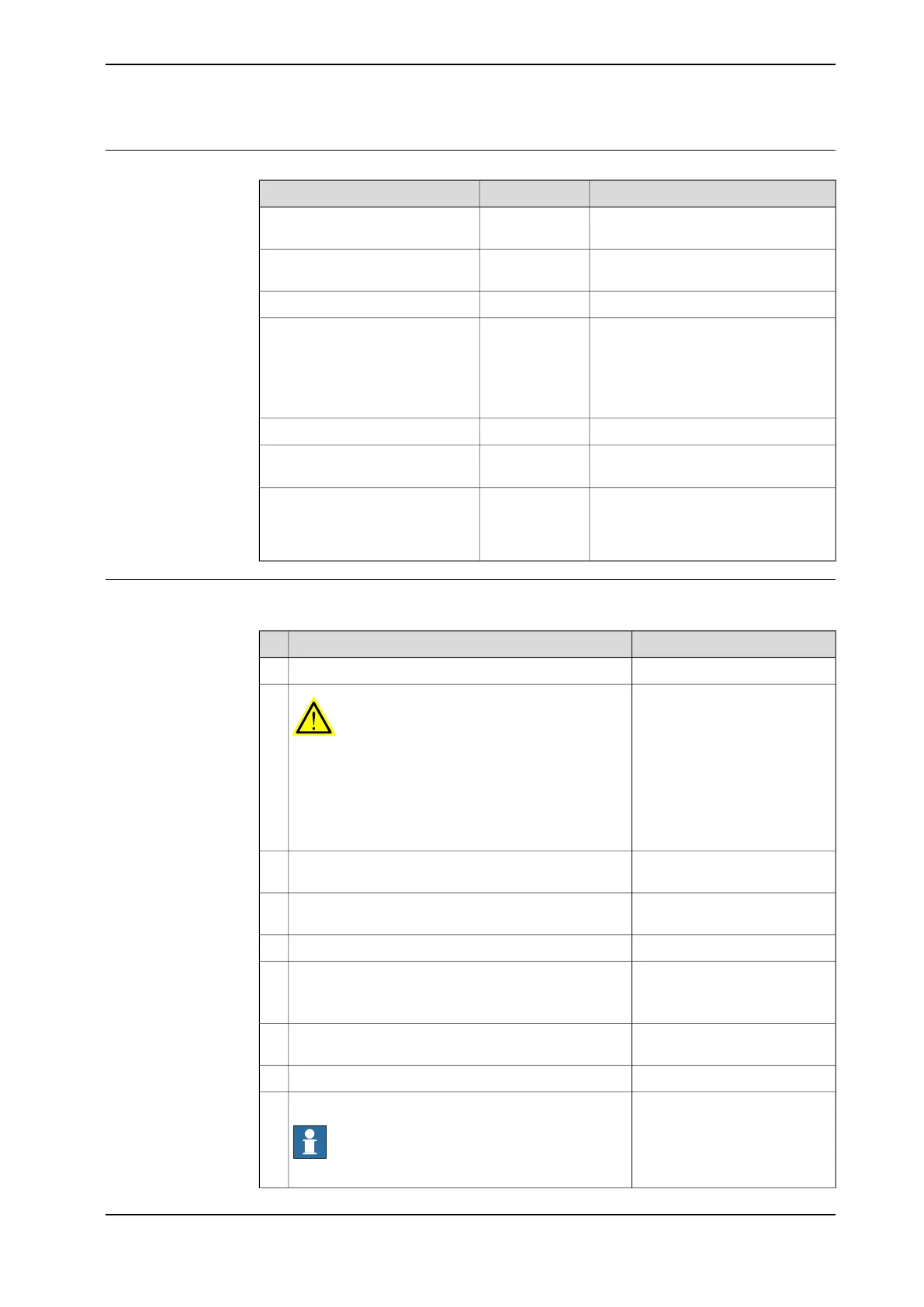

Required equipment

NoteArt. no.Equipment

3HAC039296-

001

Lubrication tool

Equivalent:

• Shell Gadus S2

3HAC042536-

001

Bearing grease

Isopropanol-Cleaning agent

Choose any of following equivalents:

• Shell: SRS Grease 4000

• Preem: Novatex Heavy EP 2

• Castrol: Entrepenadfett

• Statoil: Uniway 2X2N

-Piston rod grease

Loctite 243-Locking liquid

Content is defined in section Standard

tools on page 347.

-Standard toolkit

These procedures include references

to the tools required.

Other tools and procedures may

be required. See references to

these procedures in the step-by-

step instructions below.

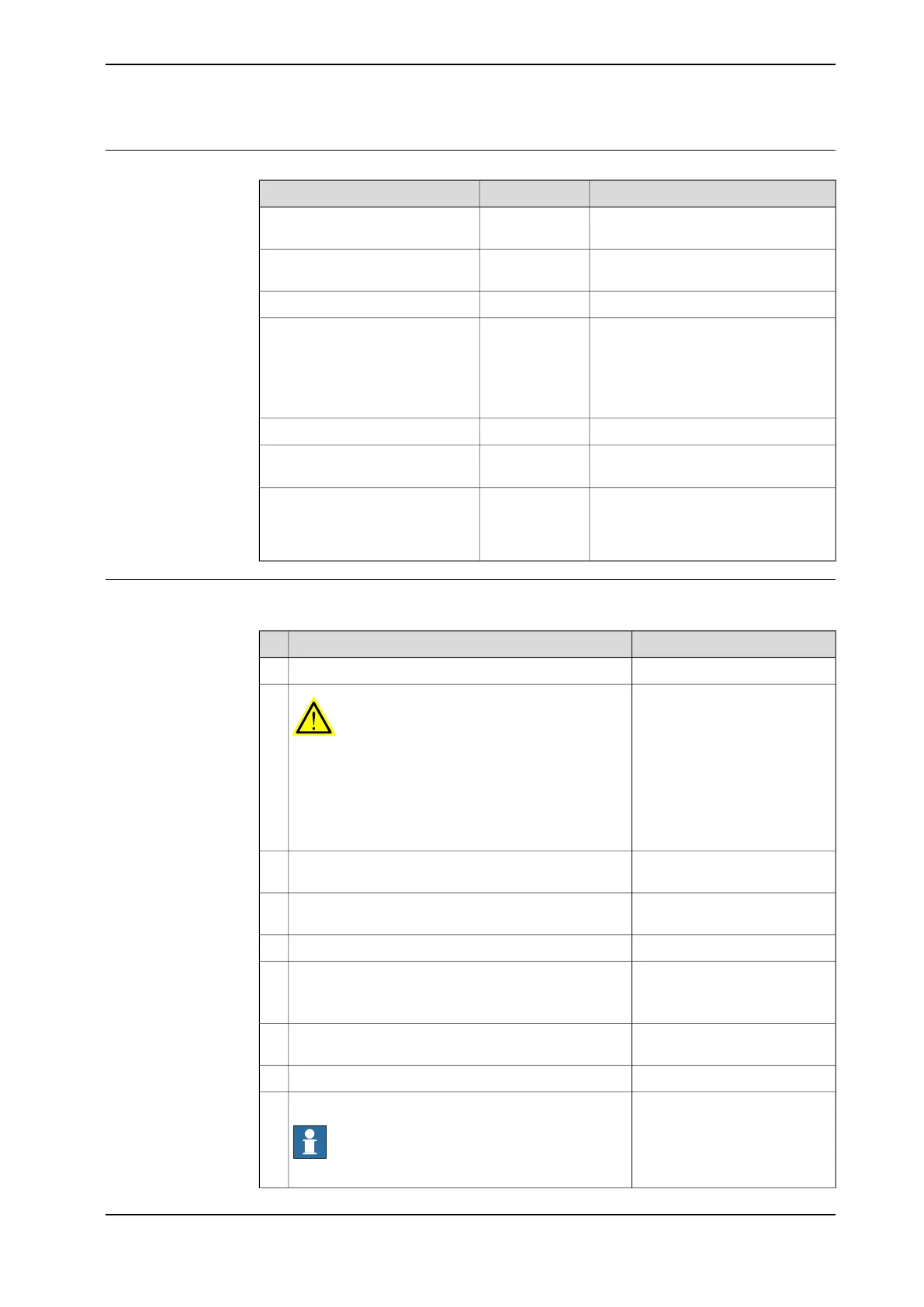

Lubricating, bearings

Use this procedure to lubricate the balancing device bearings.

NoteAction

Move axis 2 to calibration position.1

DANGER

Turn off all:

• electric power supply

• hydraulic pressure supply

• air pressure supply

to the robot, before entering the safeguarded space.

2

Be careful not to loose the sup-

port washer in the process.

Remove the locknut.3

Fit the lubricating tool. It should be tightened to the

bottom, by hand only.

4

Grease through nipple on the lubricating tool.5

Continue filling grease until clean grease exudes be-

hind the inner sealing ring.

6

Repeat this procedure at the other bearing!

Also clean of old grease on the

inner side!

Remove the lubricating tool and clean the threads on

the shaft ends of grease.

7

Apply some grease to the support washers.8

Tightening torque on lock nuts:

• 120 Nm

Apply locking liquid on the lock nuts (KM10).

Note

Do not apply locking liquid on the shafts!

9

Continues on next page

Product manual - IRB 660 137

3HAC025755-001 Revision: W

© Copyright 2006-2020 ABB. All rights reserved.

3 Maintenance

3.5.1 Lubricating balancing device bearings and piston rod

Continued

Loading...

Loading...