Commissioning

52 - EN FEX300, FEX500 CI/FEX300/FEX500-EN

6.4.2 Transmitter with single-compartment housing

G01321

„A“ „B“

1

2 3

3

4

6

5

7 8

9

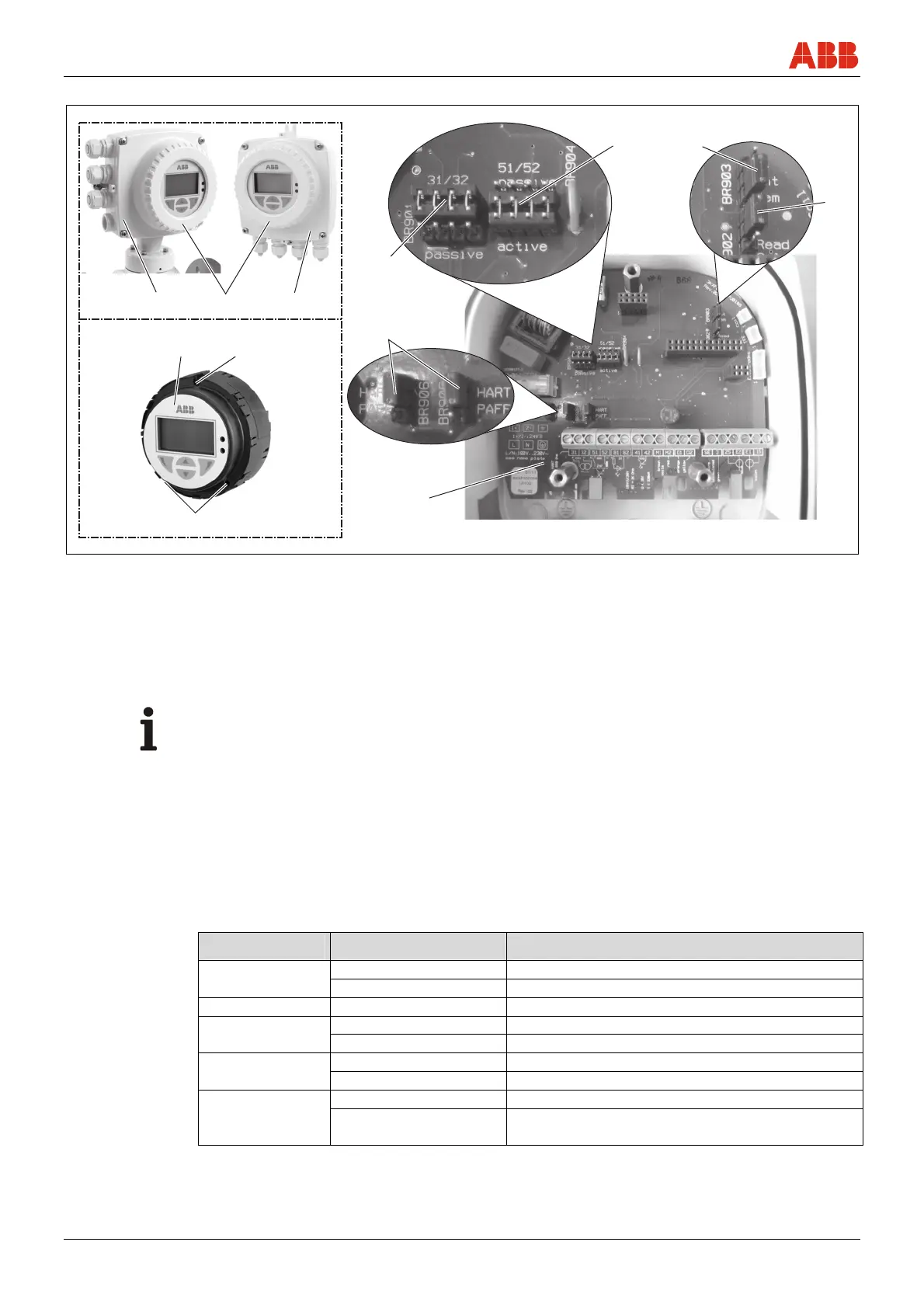

Fig. 51: Jumpers in the single-compartment housing

A Integral mount design

B Remote mount design

1 Housing cover

2 Transmitter plug-in module

3 Fixing screws

4 Backplane (in the transmitter housing)

5 Jumpers (BR905, BR906) for communication

6 Jumper (BR901) for active / passive current output

7 Jumper (BR904) for active / passive pulse output

8 Jumper (BR903) for integral / remote mount design

9 Jumper (BR902) for hardware write protection

Important (Note)

The backplane is mounted in the transmitter housing (not the transmitter plug-in module).

Configure the outputs as follows:

1. Switch off power supply.

2. Open the housing cover.

3. Remove the mounting screws for the transmitter electronics unit

4. Pull out the transmitter electronics unit

5. Set jumpers on backplane in accordance with the following table.

Jumper Number Function

BR901 active Current output 31 / 32 active

passive Current output 31 / 32 passive

BR902 Read only Hardware write protection active

BR903 integral Transmitter with integral mount design

remote Transmitter with remote mount design

BR904 active Pulse output 51 / 52 active

passive Pulse output 51 / 52 passive

BR905, BR906 HART Digital communication via HART protocol

PA/FF Digital communication via PROFIBUS PA or

FOUNDATION Fieldbus

6. Install the transmitter in reverse order.

Loading...

Loading...