- 100 -

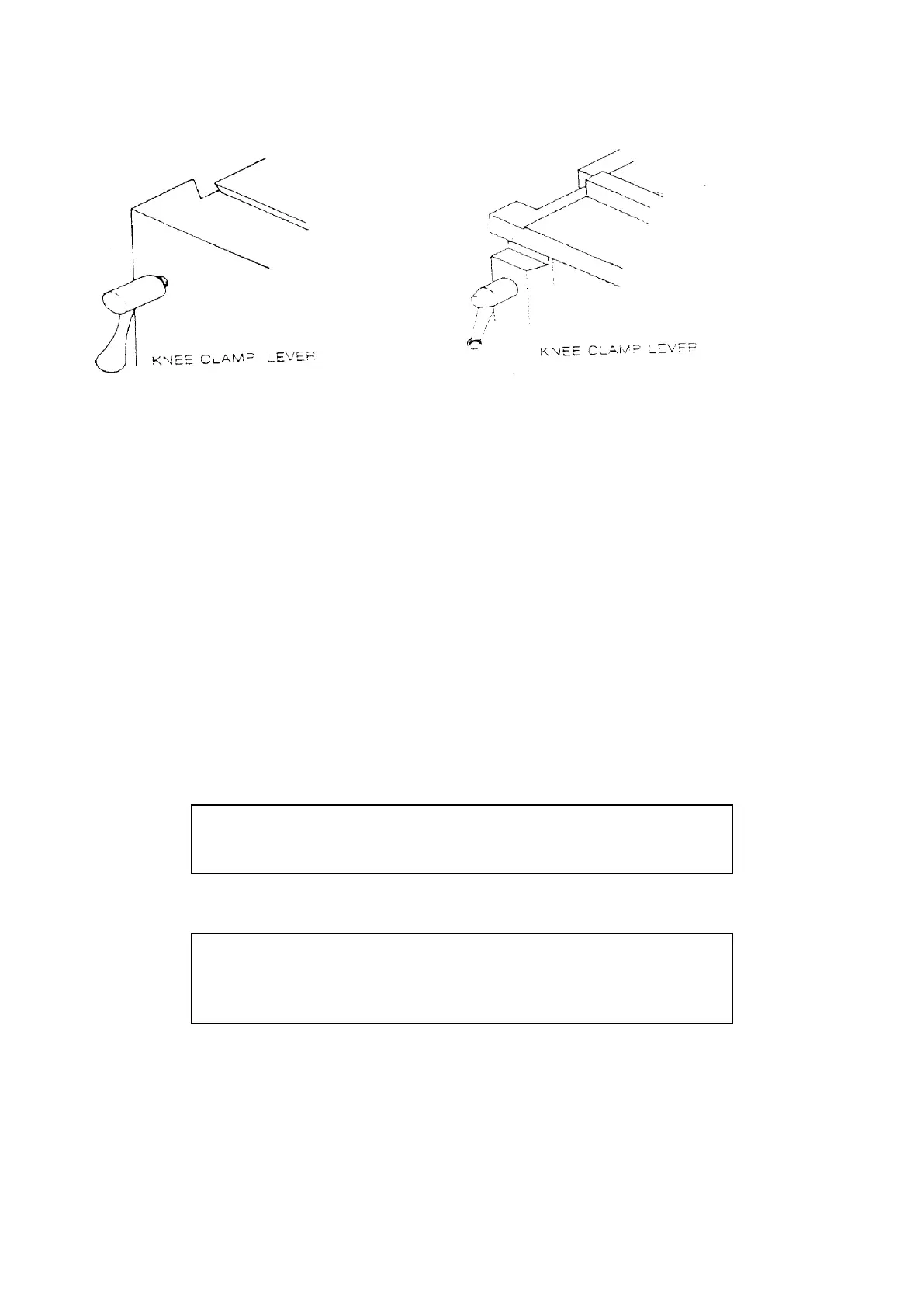

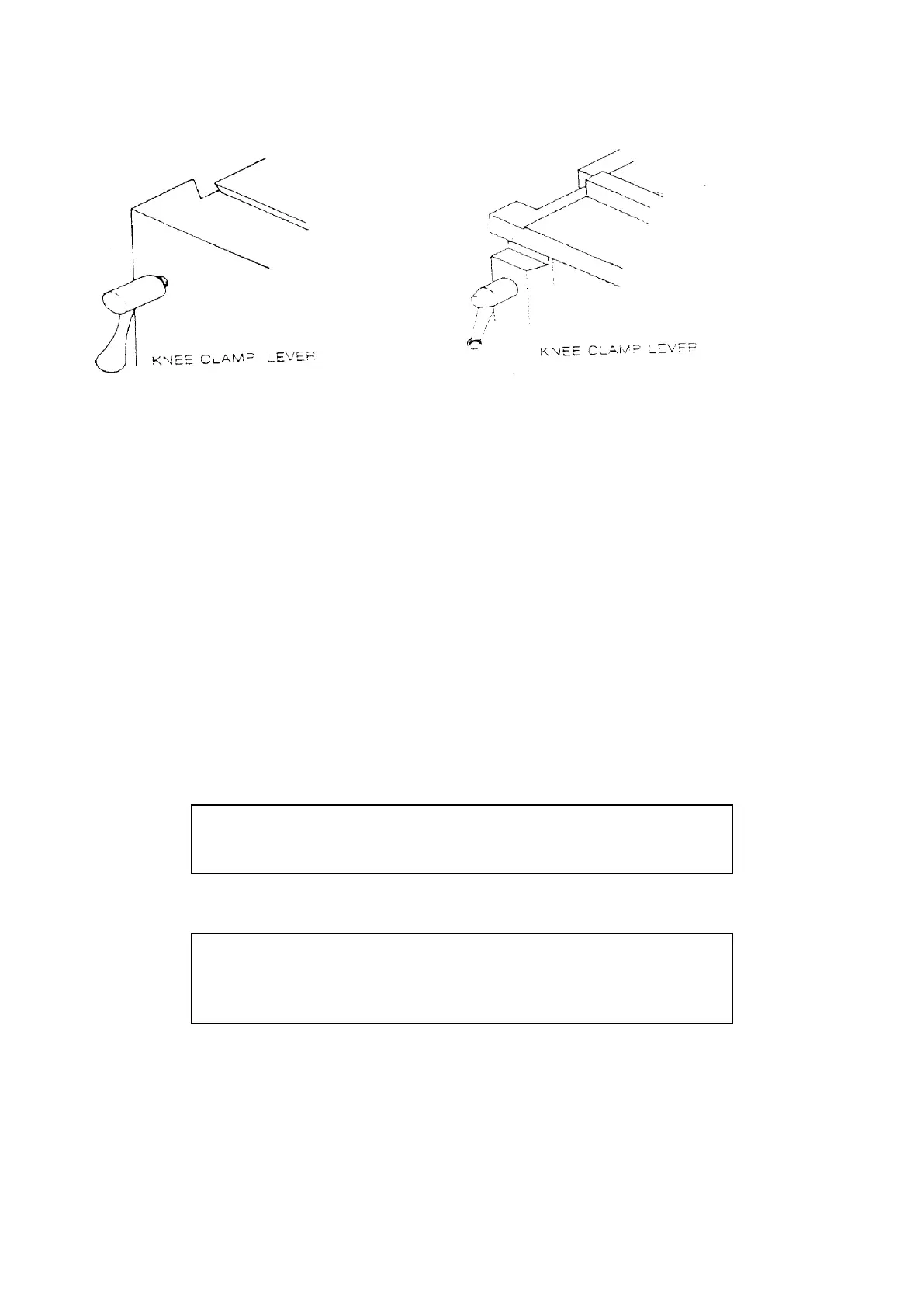

For 3VS, 3VSII & 3VK For 3VKH, 5VK & 6VK

Figure 17. Knee clamping lever

6-17. Operation Recommendations

Use 2, 3, or 4 flute end mills. Eight flute end mills are usually not as satisfactory

for general milling. When using shell mills, face mills or any other tooling, proper

machining practice should be observed.

For 3VS, 3VSII, 3VK & 3VKH

Power quill feed can be used for drills up to

3

/

8

” diameter in mild too l steel.

Overload clutch is preset to hold up to 200 lbs. down pressure on quill. Use manual

feed for drills over

3

/

8

”.

For 5VK & 6VK

Power quill feed can be used for drills up to

5

/

8

” diameter in mild tool steel.

Overload clutch is preset to hold up to 300 lbs down pressure on quill.

CAUTION

THIS CLUTCH SHOULD NOT BE TAMPERED WITH IN

THE FIELD

CAUTION

DO NOT TRY TO CHANGE SPINDLE SPEED ON E-

MILL VARISPEED HEAD UNTIL MOTOR IS RUNNING.

THIS COULD CAUSE PARTS TO BREAK.

Spindle Feeds are adjusted by turning variable resistor on the front of the belt

housing. There are two ranges shown; 60 to 500, and 500 to 4500.

60 to 500 RPM is obtained through the back-gear drive and is referred to as low

range. To engage the back-gear, use the lever marked HI-NEUTRAL-LO on the

right side of the head. Move this lever to the “LO” position and use low range on

the variable speed dial.

Loading...

Loading...