- 98 -

6-15 Ram Position

A. Ram can be moved by loosening three ram lock studs on turret and moving to

desired position.

CAUTION

CARE SHOULD BE TAKEN TO LOCK RAM SECURELY

AFTER SETTING.

NOTE

It is recommended that on heavy milling work, head should

be kept as close to column as possible, where maximum

rigidity is obtained.

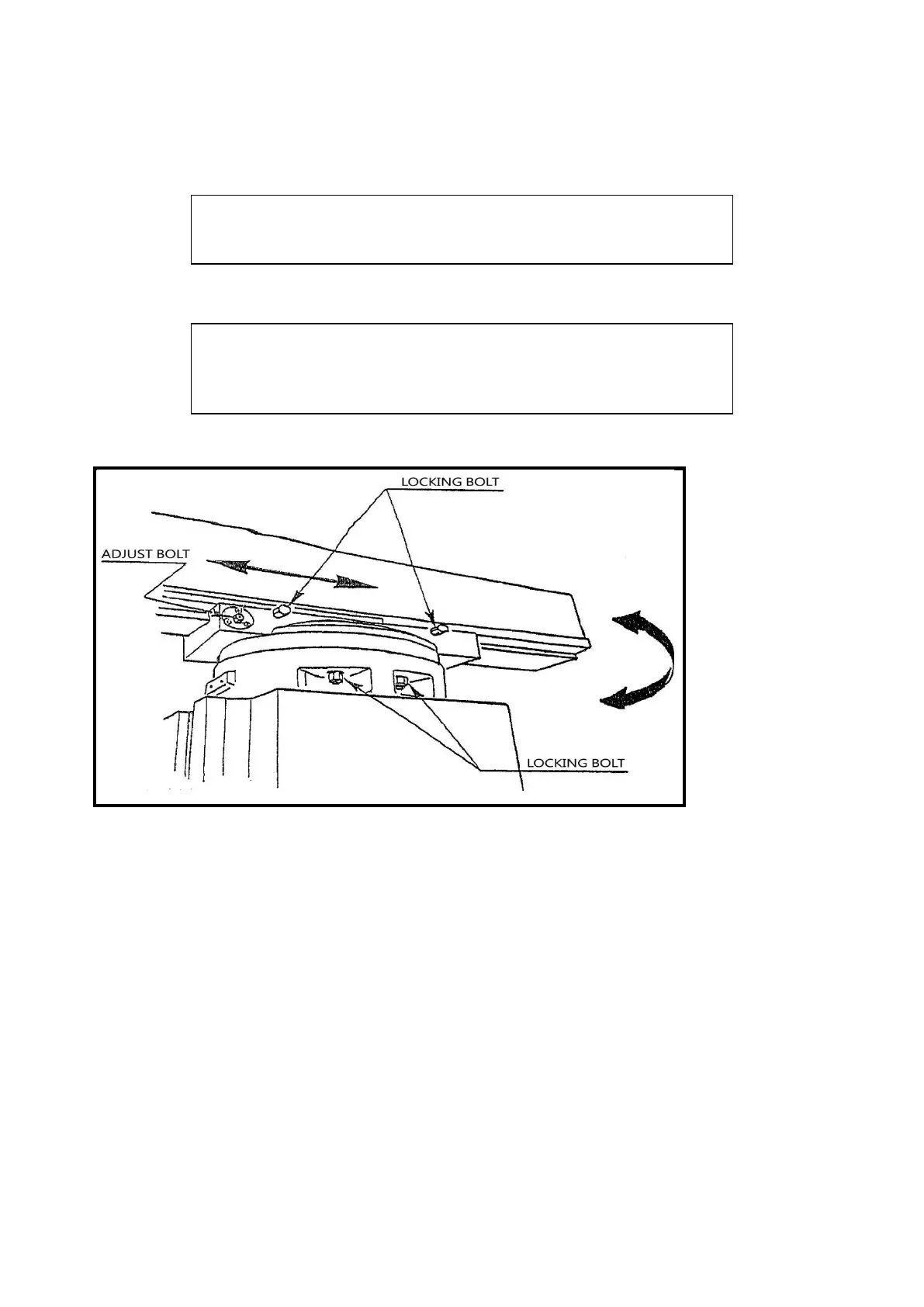

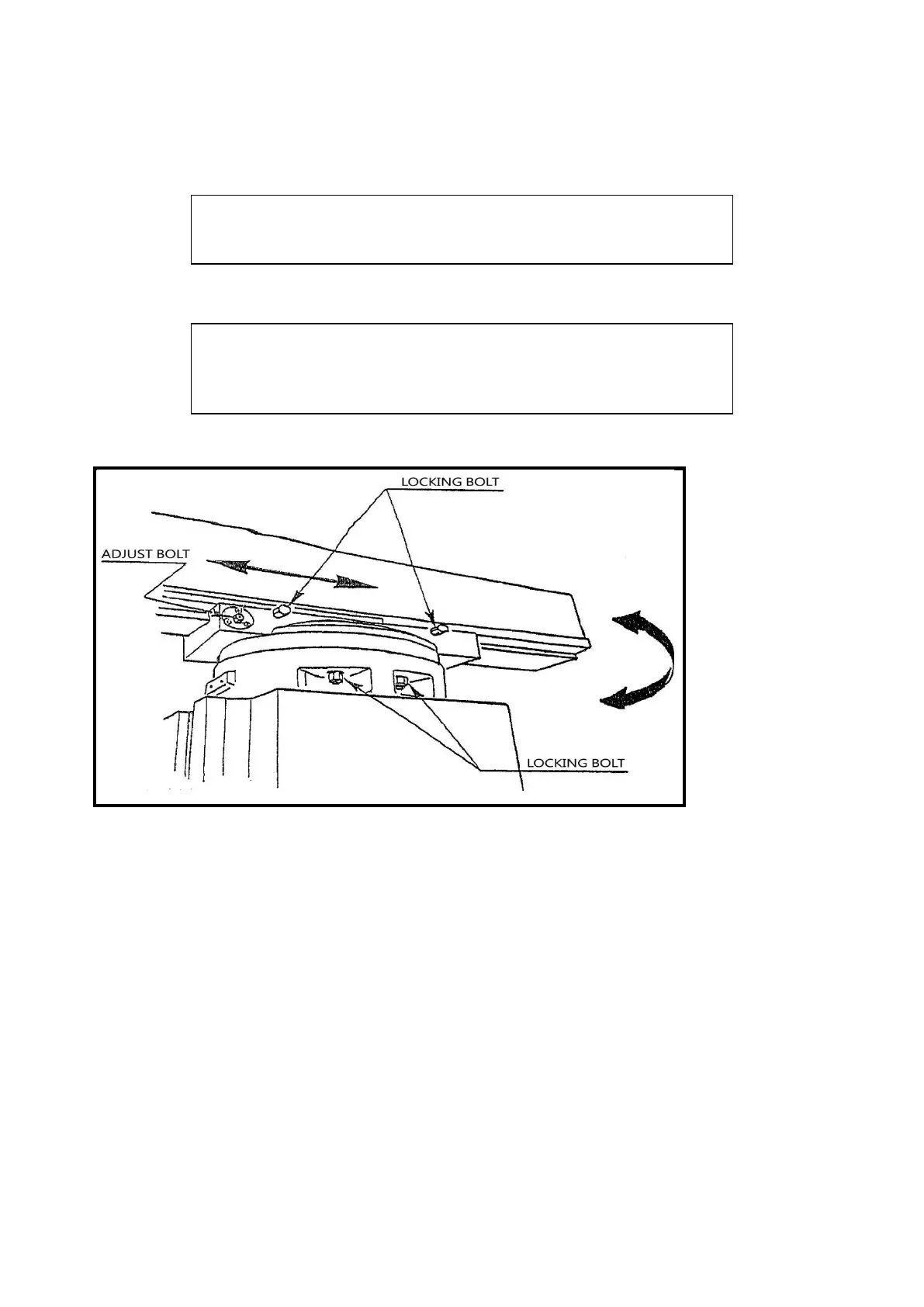

B. Swiveling Turret and Moving Ram on 6VK

SWIVELING TURRET:

1. USE SPANNER WRENCH TO UNLOCK THE FOUR

LOCKING BOLTS.

2. ROTATE TO THE REQUIRED ANGLE SETTING.

3. LOCK THE FOUR BOLTS.

MOVING RAM:

1. USE SPANNER WRENCH TO UNLOCK THE TWO BOLTS.

2. TURN THE ADJUSTMENT BOLT TO MOVE THE RAM TO

THE REQUIRED POSITION.

3. LOCK AND TIGHTEN THE REAR BOLT FIRST, THEN THE

FRONT ONE.

6-16 Clamping Table, Saddle and Knee:

When milling with longitudinal table feed only it is advisable to clamp the knee to

the column and the saddle to the knee to add rigidity to these members and provide

Loading...

Loading...