Benchmark 2.0 LN Installation, Operation & Maintenance Manual

CHAPTER 9 – RS232 COMMUNICATION

OMM-0046_0J AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 Page 111 of 168

GF-123 Ph.: 800-526-0288 06/18/2015

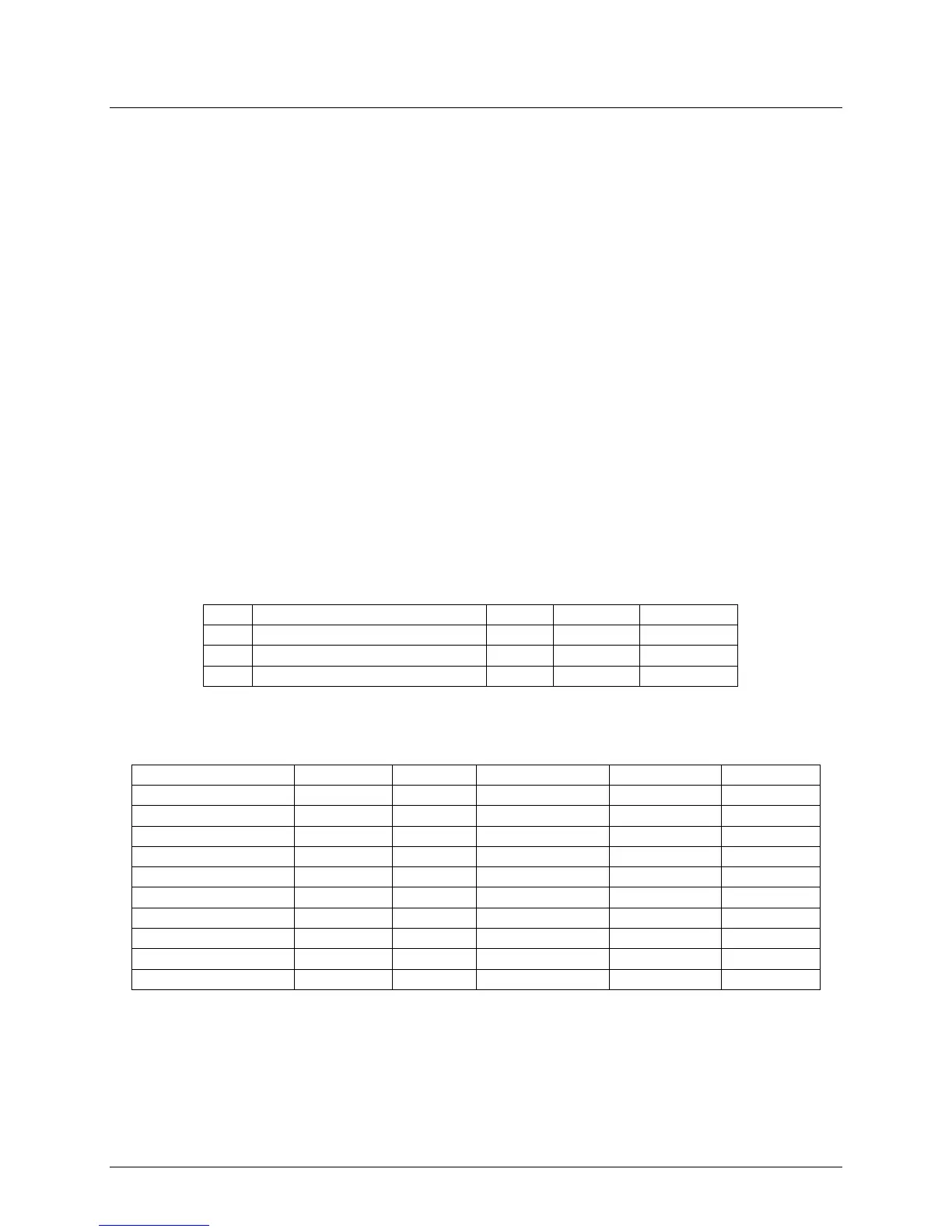

flame strength must change by more than 5%, or the run mode must change. At steady-state,

the run-length is allowed to reach a maximum of 30 minutes before the record is logged. This

means that no more than 30 minutes of data can be lost if the unit loses power. Table 9-2

shows a sample Operation Time Log for a boiler:

The Operation Time Log can only be accessed through the RS232 interface using a laptop or

other terminal device. Ten operation time records are displayed for each T command entry. The

operation time log can be cleared ONLY by factory authorized personnel using the Clear Log

option in the Factory menu.

NOTE

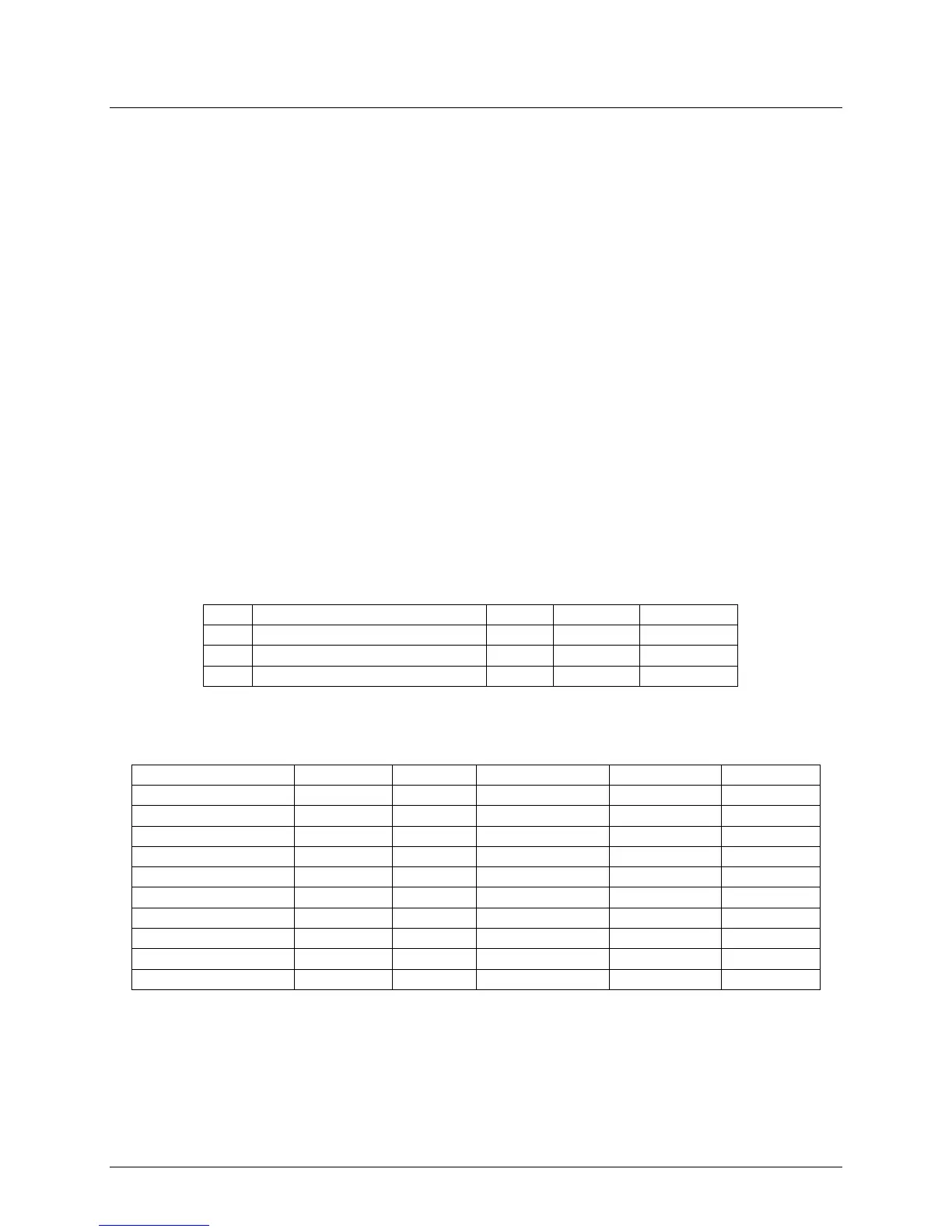

The Sensor (S) Log can store up to 1200 records. Therefore, to view the

most recently logged record, enter “S” followed by 0 (zero) and then press

Enter (i.e. S0 <Enter>). To view earlier records in reverse chronological

order, enter S and press Enter. To go back 200 or 700 records, enter S200

or S700, etc. and press Enter.

9.4.3 Sensor Log

The sensor values can be logged at a different rate if needed by setting the Sensor Log Interval

in the Diagnostics Menu. The log interval can vary from once every minute to once every day.

Table 9-3 shows a sample Sensor Log every 5 minutes for a boiler running in Constant Setpoint

mode.

Table 9-1. Sample Fault Log Display

Direct Drive Signal Fault

Table 9-2. Sample Operation Time Log Display

Loading...

Loading...