Benchmark 2.0 LN Installation, Operation & Maintenance Manual

CHAPTER 4 – INITIAL START-UP

OMM-0046_0J AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 Page 55 of 168

GF-123 Ph.: 800-526-0288 06/18/2015

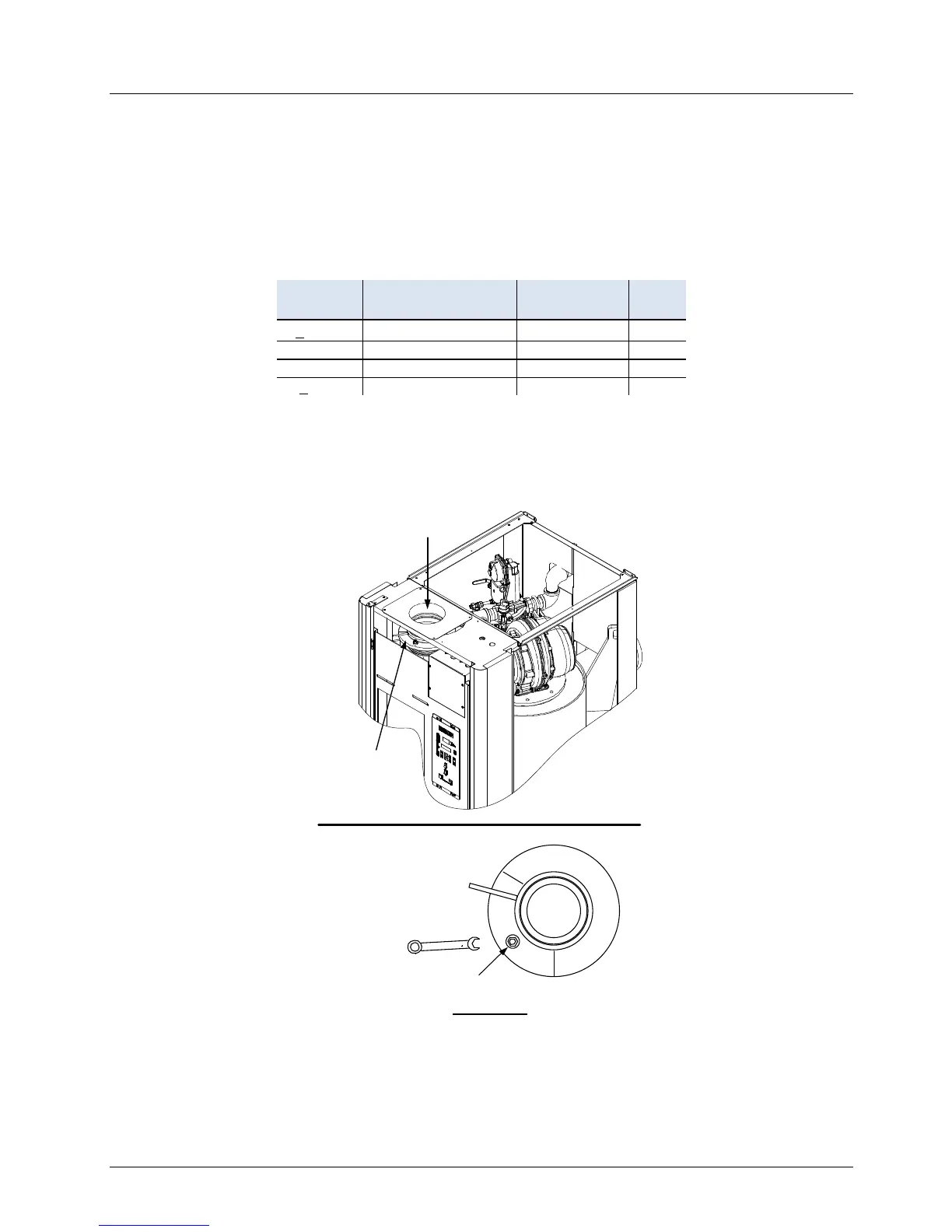

12. With the valve position at 100%, insert the combustion analyzer probe into the flue probe

opening and allow enough time for the combustion analyzer reading to stabilize.

13. Compare the measured oxygen level to the oxygen range for the inlet air temperature

shown in Table 4-1. Also, ensure that the carbon monoxide (CO) and nitrogen oxide (NOx)

readings do not exceed the values shown.

Table 4-1: Combustion Oxygen Levels for a

100%

Air/Fuel Valve Position

14. If necessary, adjust the iris air damper shown in Figure 4-5 until the oxygen level is within

the range specified in Table 4-1.

15. Once the oxygen level is within the specified range at 100%, lower the valve position to

80%.

AIR

INLET

IRIS AIR

DAMPER

(SEE VIEW

“A”)

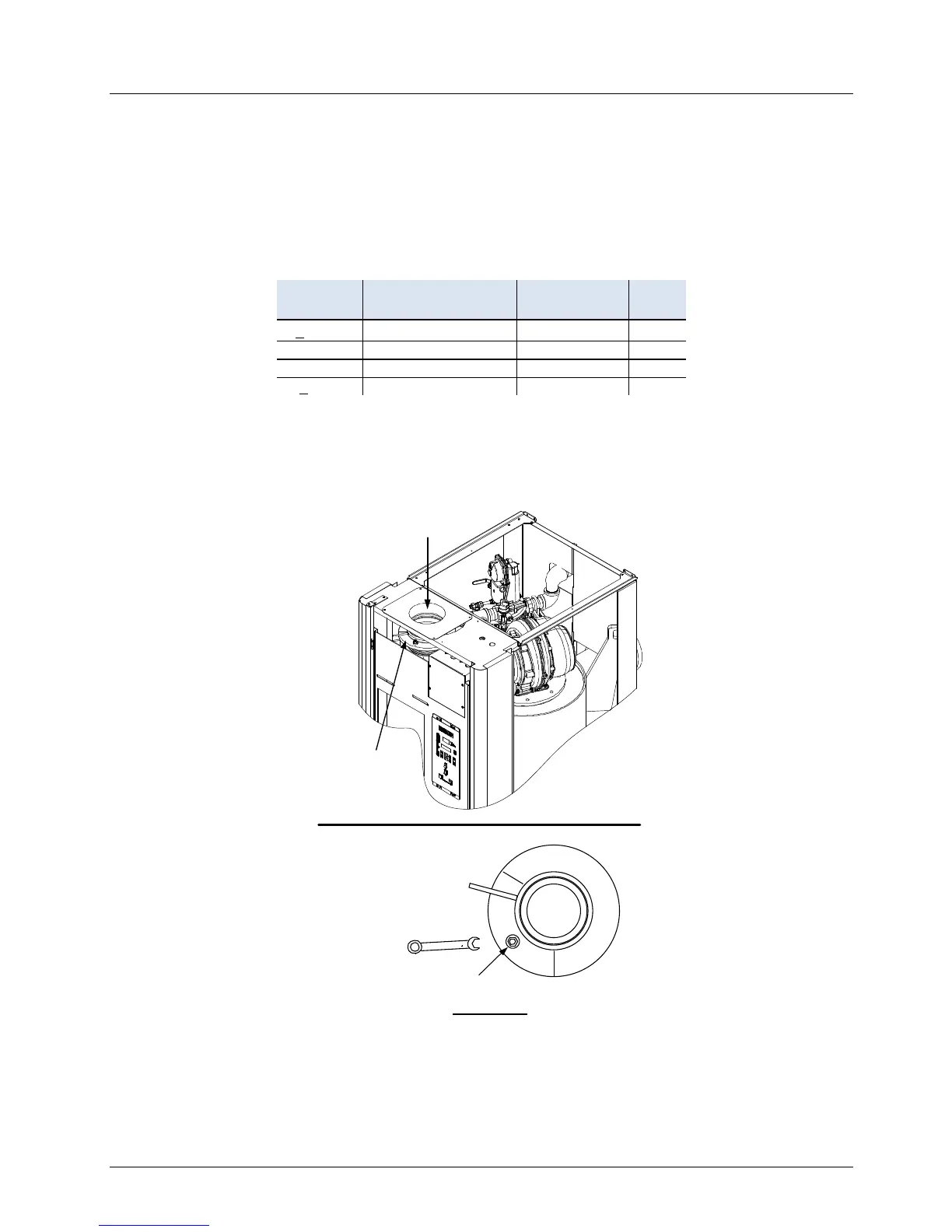

USE 1/2"

WRENCH TO

INCREASE

(CW) OR

DECREASE

(CCW) INLET

AIR

IRIS

ADJUSTMENT

VIEW A - A

Figure 4-5: Iris Air Damper Location/Adjustment

NOTE

The remaining combustion calibration steps are performed using

the Combustion Cal Menu included in the C-More Control System.

Loading...

Loading...