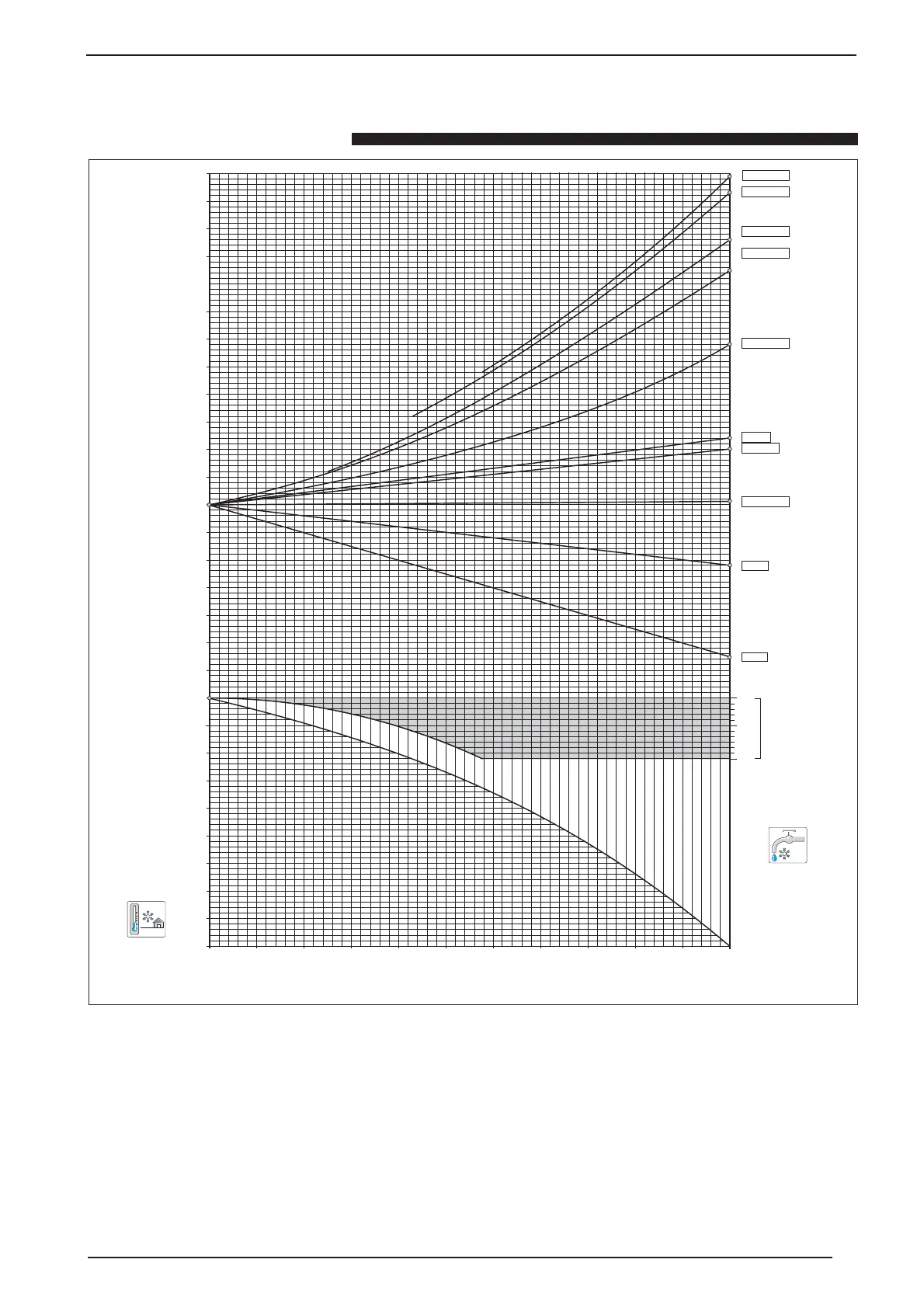

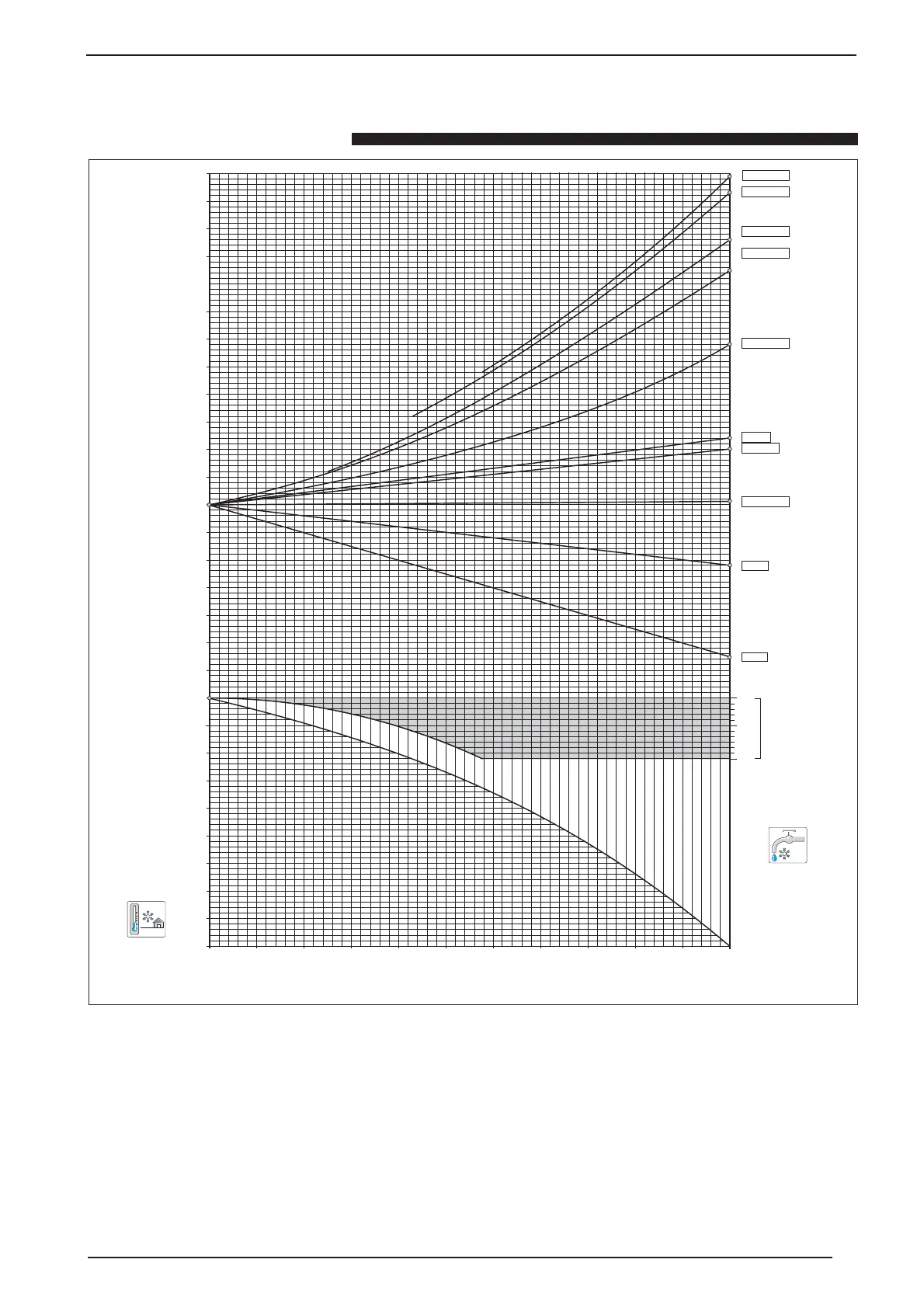

21

Ethylene glycol solution

-30

-25

-20

-15

-10

-5

0

5

0 5 10 15 20 25 30 35 40 45 50

-35

0,99

0,98

0,97

0,96

0,95

1,00

1,10

1,20

1,30

1,40

1,50

1,60

1,70

1,80

1,90

2,00

2,10

-35

55

-40

0,94

2,20

FcGPf

FcGPa

FcGPf (PdC)

FcGQPdc

FcGQF

FcGDpF (d)

FcGDpF (c)

FcGDpF (b)

FcGDpF (a)

FcGDpF (e)

Fattore correttivo

Temperatura aria esterna

(°C)

% GLICOLE

Temperatura

acqua prodotta (°C)

5

-6

(1)

0

Key::

FcGPf =

Correction factor

of the cooling

capacity

FcGPa =

Input power

correction factor.

FcGDpF (a) =(Evaporator) pressure drop

correction factor (evaluated with an

average temperature of -3.5 °C)

FcGDpF (b) = Correction factor of the

pressure drops (average temperature =

0.5 °C)

FcGDpF (c) = Correction factor of the

pressure drops (average temperature =

5.5 °C)

FcGDpF (d) = Correction factor of the

pressure drops (average temperature =

9.5 °C)

FcGDpF (e) =

Correction factor of the

pressure drops (average temperature =

47.5 °C)

FcGQF =Flow rate (evap) correction

factor mean temperature

=

9.5 °C)

FcGQC =Flow rate (condenser) correction

factor mean temperature

=

47.5 °C)

The water flow rate and pressure drop

correction factors must be applied

directly to the data obtained for operation

without glycole.

fig. 03

Loading...

Loading...