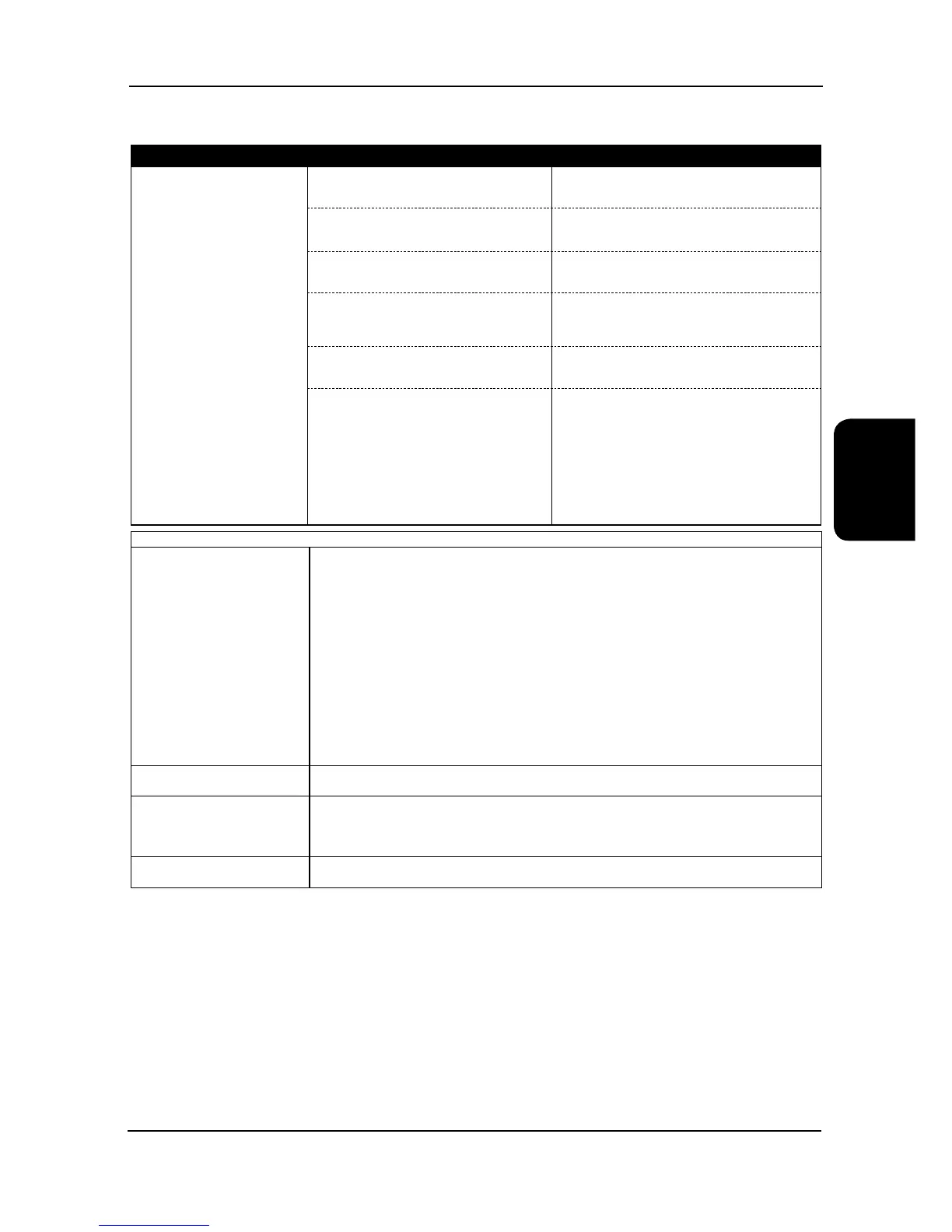

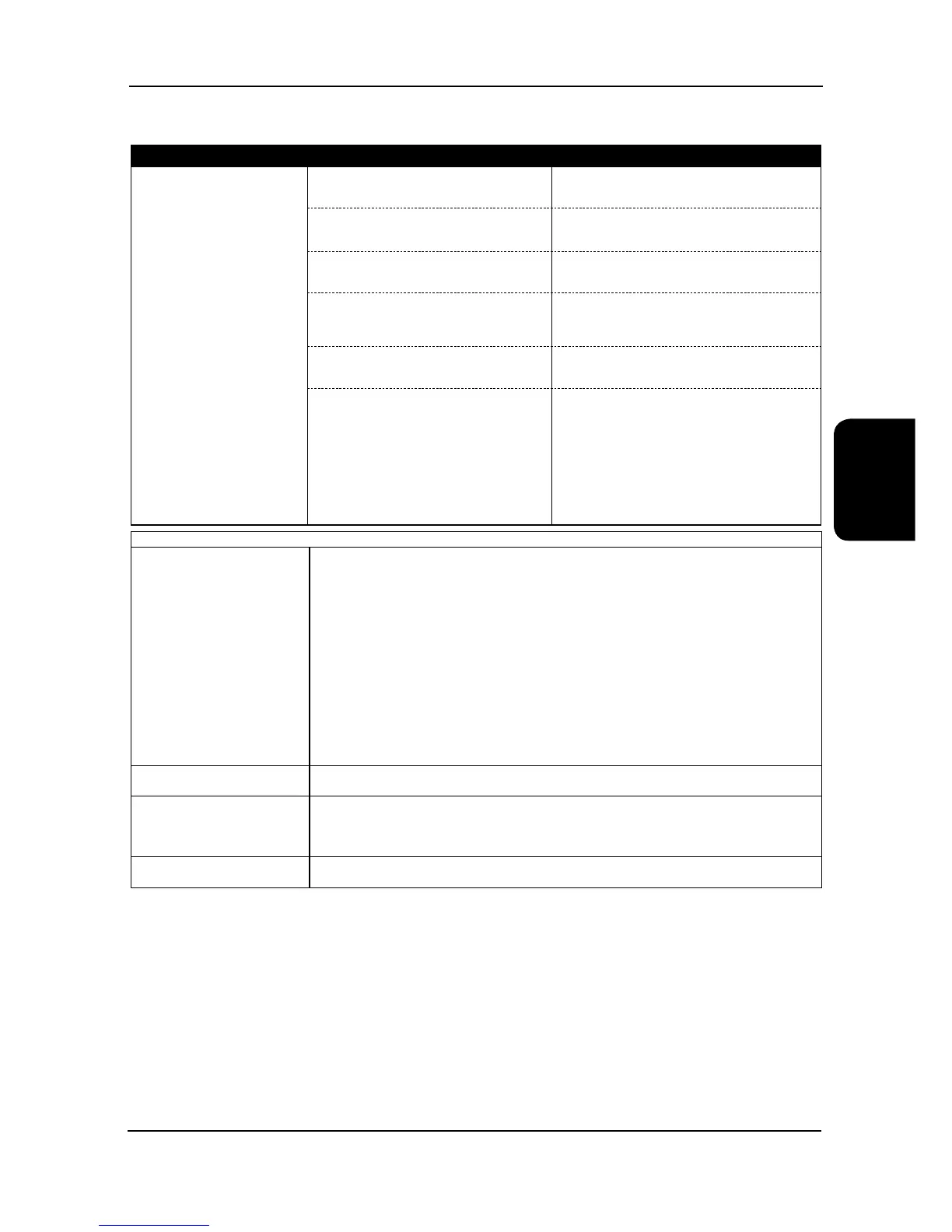

FAULT POSSIBLE CAUSE REMEDY/ACTION

High room temperature

Damper not operating correctly

Damper jammed in free cooling position

during high ambient conditions.

Compressor(s) not operating. See unit not operating power off - power on.

Compressor(s) not operating efciently.

Important: Check electrical phase rotation.

Fit gauges and investigate.

Heatload too great for system.

High ambient affecting condenser

performance. Investigate design and loads -

clean coil ns.

Low airow Dirty lters - replace.

Control malfunction.

Check transformer/secondary supply -

replace if faulty.

Recalibrate controls if necessary.

Check motor and wiring from controller.

Check sensor not short-circuited - repair/

replace.

Compressor not operating. No power to compressor. Check electrical connectors, isolator,

MPCBs,contactor and control circuit wiring

action. Always investigate fuse/contactor

problem before replacements.

Compressor discharge gas temperature

protection device open.

Allow time to reset. Internal device, change

compressor if it does not reset.

Defective compressor motor. Check windings resistance. If burnt out follow

burn out procedure using drier in suction line.

Always replace the contactor.

Klixon tripped and does not reset. Sometimes it takes up to 4 hours to reset.

Replace compressor if necessary.

Low pressure switch operated (large or

complete loss of refrigerant charge).

Repair leak and recharge system. Evacuate

before charging using good refrigeration

practice.

Fan tripped. Fan motor seized. Free motor or replace.

Fan jammed. Remove obstruction.

Low evaporating temperature. Low refrigerant charge. Recharge refrigerant. (R410A)

Expansion valve faulty or incorrectly set. Replace or adjust expansion valve.

Insufcient airow through evaporator

coil.

Check lter for clogging and fan speed.

Excessively high evaporating

temperature.

Expansion valve faulty. Replace valve.

Troubleshooting

Loading...

Loading...