Maintenance

Refrigeration

Service Tools/Test Equipment

• Refrigerant Manifold gauges

• Spanners

• Voltmeter

Safety Equipment

• Safety Glasses / Goggles

• Gloves

• Overalls

Procedures

HP/LP Safety Pressure Switch Settings

Check operating of HP / LP cut-out,

Settings

LP cut-out – (Auto reset for 3 times when the Low Pressure is detected over a period of 1 hour)

Has a 2 minute delay on start-up (similar to a Low ambient kit)

Low pressure cut-out 0.5 +/- 0.2 Barg

HP switch (manual reset): High pressure switch 40.25 bar +/- 1 Barg

HP limiting function 35 barg / 2 barg differential (this reduces the number of compressors operating i.e. 2 comp and

down to 1 comp.

Compressor Oil Level (Full load)

Check the compressor oil level at full load. (record oil level)

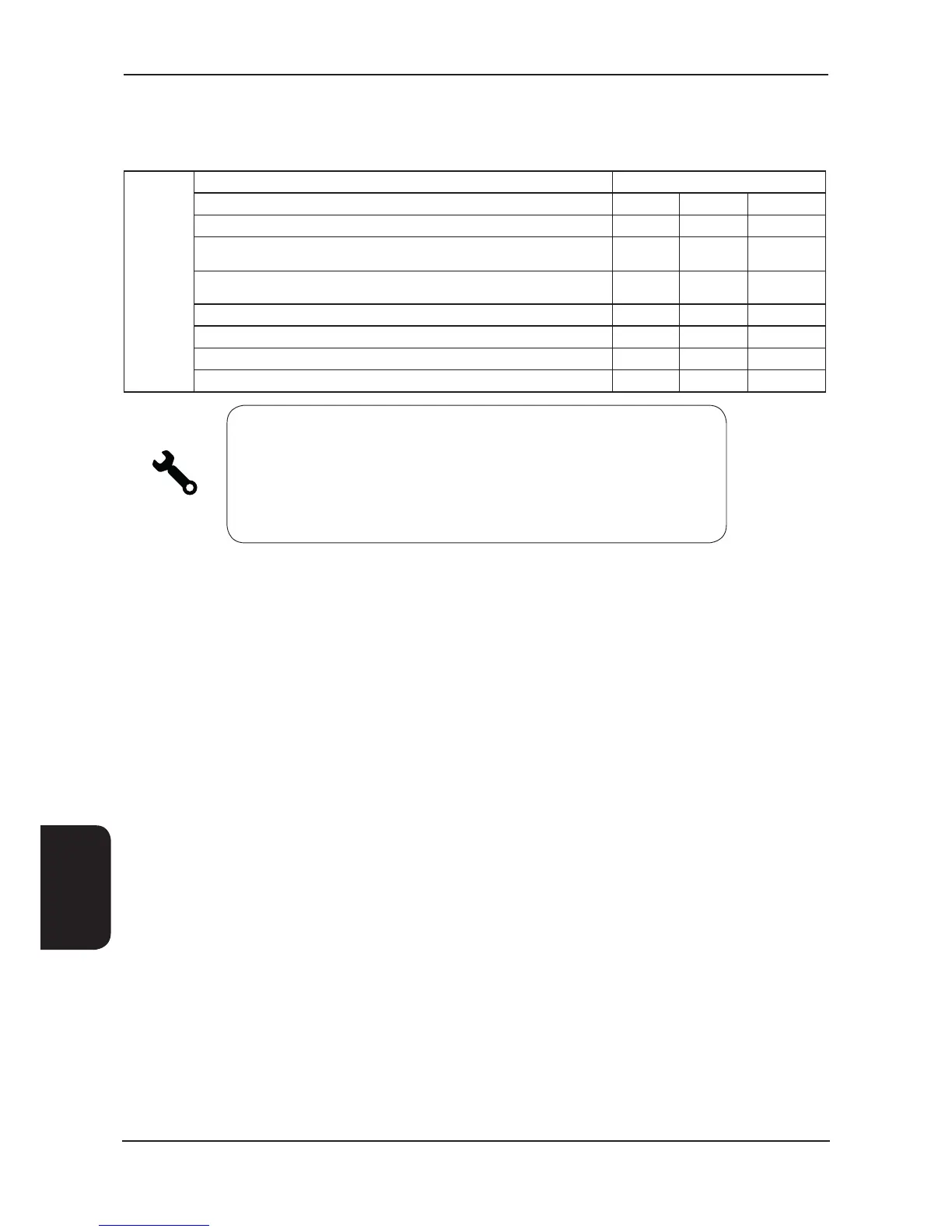

Refrigeration

Task Frequency

Compare the following and compare results with commissioning records:

3 Months 12 Months 60 Months

Suction, Liquid and Discharge pressures ●

Refrigeration system temperatures, Suction, Liquid and Discharge. Record

superheat and subcooling temperatures

●

Check each circuit sight glass for dryness and bubbles for indication of leaks ●

Head pressure control is maintained ●

Record details on F-Gas record ●

Check compressor oil level ●

Pressure relief valves ●

Loading...

Loading...