Service Tools/Test Equipment

• Spanners

• Manometer

• Thermometer

• Refractometer

Safety Equipment

• Safety Glasses / Goggles

• Gloves

• Overalls

Maintenance

Waterside

Procedures

Binder Points

Binder points should be tted to both the ow and return pipe work adjacent to the evaporator.

Water Strainer

A water strainer must be tted to the inlet side of the evaporator.

Failure to do so may result in severe damage and will void the AIREDALE warranty.

Water Flow Rate

Check that the design water ow rate is available to the unit. If not available do not turn unit on.

Waterside Pressure Drop

Measure the waterside pressure drop of the unit ensuring that the pump (if tted) is operating.

Glycol Strength

Check and record the glycol type and strength. Low levels of glycol can cause freeze up problems when operating at

low temperatures or during the unit off state during cold ambient conditions.

Glycol concentration is measured by use of a Refractometer.

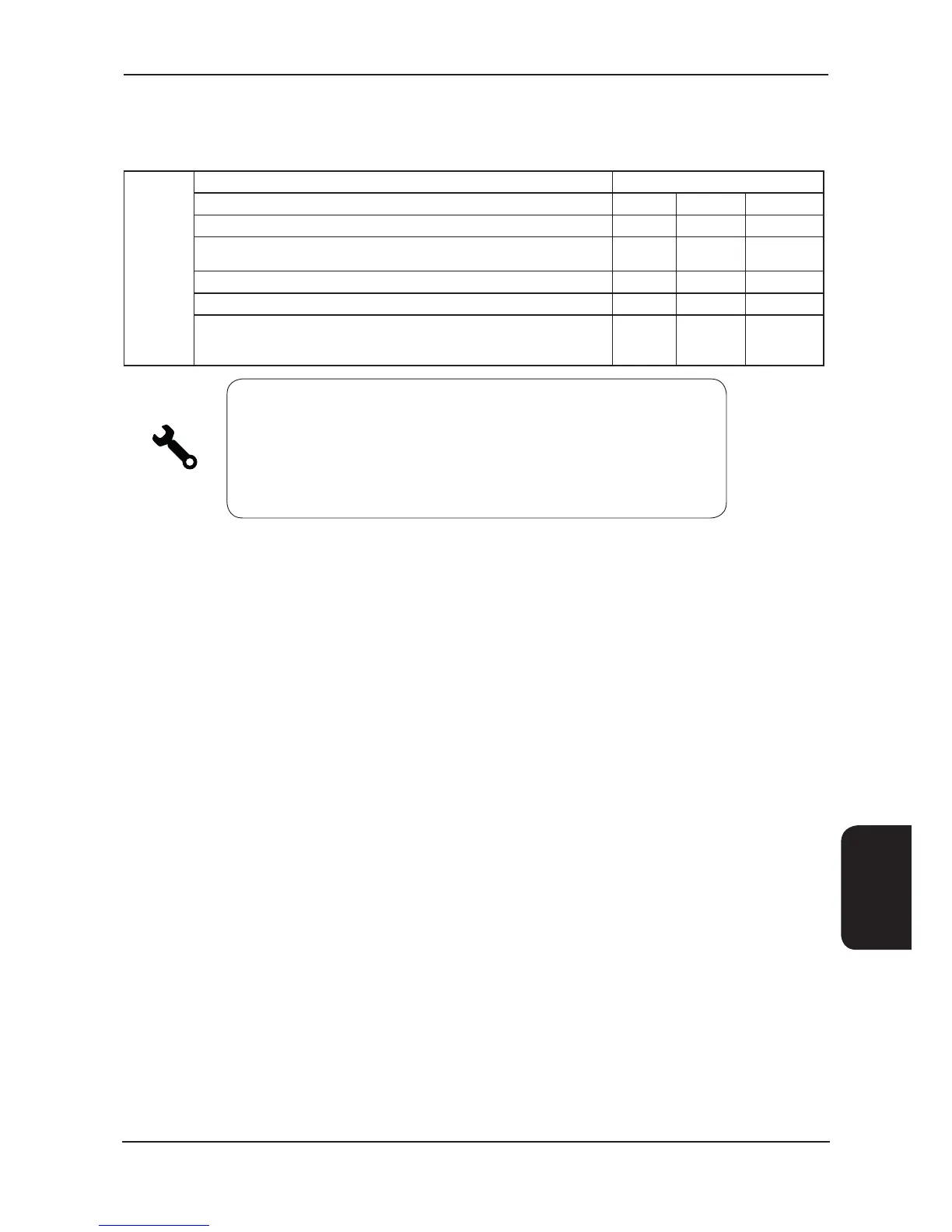

Waterside

Task Frequency

3 Months 12 Months 60 Months

Check pressure drop of water strainer. If excessive clean the strainer ●

Visually inspect pipe and pipework insulation. Check pipework clamps are

secure

●

Inspect for water leakage ●

Check pressure drop of evaporator. If excessive clean evaporator ●

Check condition of Water/Glycol solution to ensure that the system is protected

against corrosion, scale and microbiological fouling, ensuring maximum heat

transfer efciency

●

Loading...

Loading...