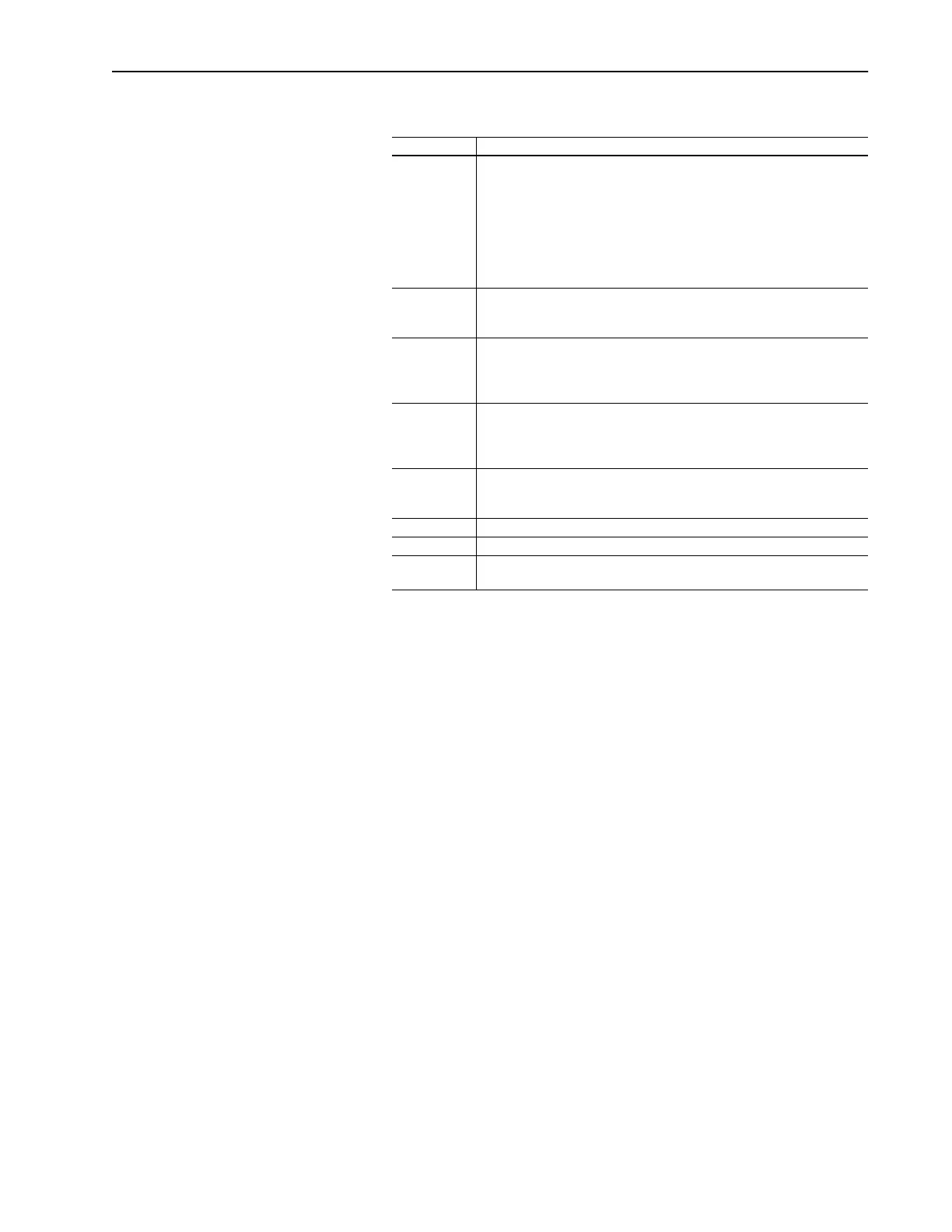

Creating Ladder Logic Programs 4–9

About the PLC Ladder Logic Program

Rung Description

0001 When the machine Start push button is pressed, the PLC sends a START

command to the drive. The drive will start if no STOP command is being sent

by the PLC or any other control device. (Start button is a normally open

contact in this example.) SCANport products will start only if the start bit

transitions high while the stop bit is already low.

The address (O:020) is determined by the rack and starting group settings

on the module. In the example, we use rack 02 and starting group module

word 0.

0002 When the machine Stop push button is pressed, the PLC sends a STOP

command to the drive. (Stop button is normally closed contact in this

example)

0003 A frequency command is transferred from the PLC data table to the drive. A

range of 0 to 32767 is equivalent to zero to maximum frequency. (In this

example, the drive frequency select parameters are set to receive a

frequency reference from the Remote I/O module.)

0004 When the machine Jog button is pressed, the PLC will send a JOG

command to the drive. The drive will start and run at the programmed jog

frequency if no STOP command is being sent by the PLC or other control

device. (Jog button is normally open contact in this example.)

0005 When the machine Clear Faults push button is pressed, the PLC sends a

CLEAR FAULTS command to the drive. (Clear Faults button is a momentary

normally open contact in this example.)

0006 When the drive is running, the PLC will receive a Drive Running status bit.

0007 When the drive is faulted, the PLC will receive a Drive Faulted status bit.

0008 A value is moved from the PLC data table into the drive parameter specified

by the Data In A1 parameter in the drive.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Loading...

Loading...